High-efficiency vertical crushing device

A crushing device and high-efficiency technology, which is applied in recycling technology, grain processing, mechanical material recycling, etc., can solve the problems of increasing economic costs, reducing work efficiency, and waste of electric energy, and achieves convenient operation, improved efficiency, and improved conveying efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

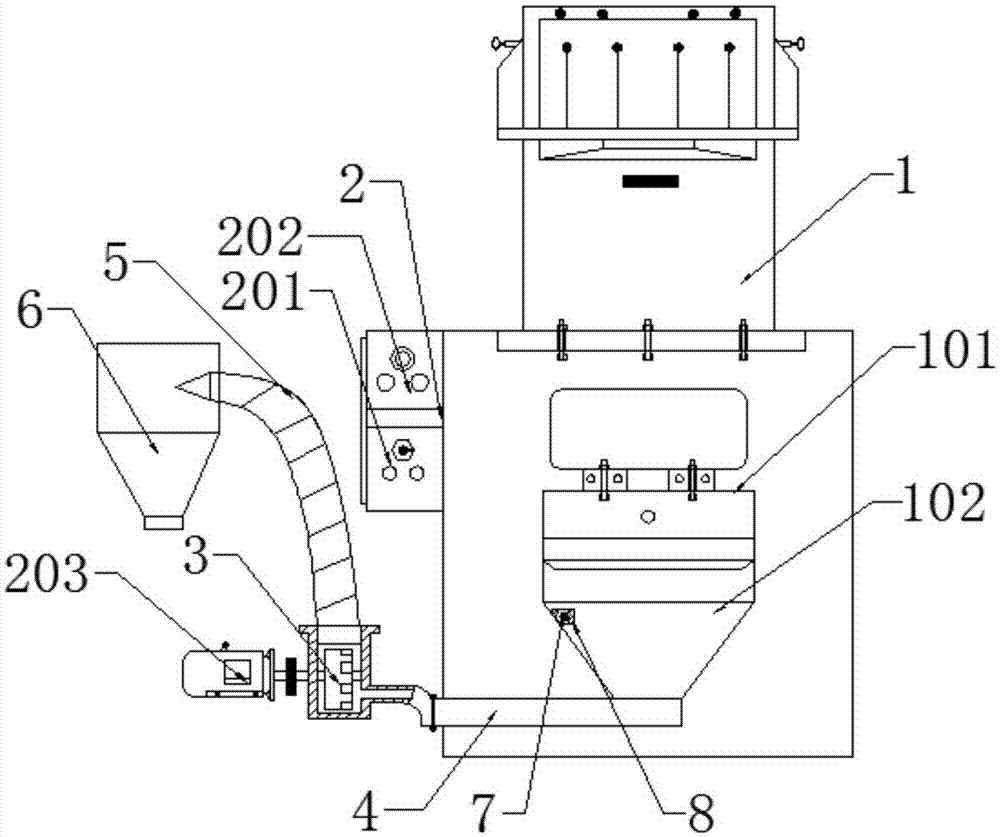

[0019] Such as figure 1 As shown, the present invention provides a high-efficiency vertical pulverizing device, including a pulverizer body 1, a fan 3 and a control system 2, the fan 3 is arranged at the lower outside of the pulverizer body 1, and the control system 2 is arranged at the bottom of the pulverizer body 1 Outer middle. The discharge port at the bottom of the pulverizer body 1 is connected to the feed port of the fan 3 through the pipe I4, and the discharge port of the fan 3 is connected to the recovery bin 6 through the pipe II5. Based on the purpose of convenient installation and equipment layout, as a preference, the pipe I4 can use hard pipes, which has a high degree of integration and can reduce the occupied area of the whole machine; while the pipe II5 can use plastic hoses, this structure can According to the specific installation space, adjust the appropriate installation scheme, which is flexible and convenient.

[0020] A pulverizing chamber 101 is se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com