Automatic hydraulic numerical-control tube bending machine

A pipe bending machine and hydraulic technology, applied in the field of machinery, can solve the problems of difficulty in forming batches, inability to achieve springback compensation, and bending qualified arc pipe fittings, so as to reduce the workload of shape calibration, reduce the difficulty of quality control, and satisfy the The effect of machining accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with drawings and embodiments.

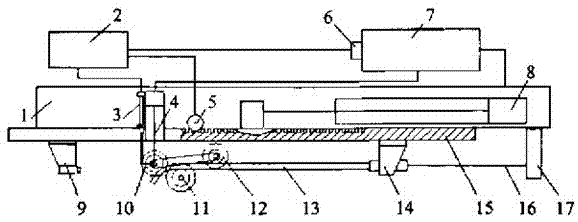

[0013] Such as figure 1 , the fully automatic hydraulic CNC pipe bending machine is mainly composed of bed, industrial computer, displacement sensor, Y cylinder, photoelectric encoder, X, Y servo valve, hydraulic servo system, X cylinder, feeding bracket, moving wheel, fixed roller, It is composed of a roller, a rectangular tube, a jacking bracket, a slide rail, a core holder and a core holder bracket.

[0014] According to the design graphics of the bar to be processed, the special software installed at random generates the plane curve data of each point of the pipe in the "edit" interface (can be edited and modified), and enters the "control" interface to generate control data. After the "automatic" start, the Y cylinder returns, and the slide rail moves to the right together with the pipe to be bent to realize the "feeding" process. During the "bending" process of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com