Circulation type shell mould pouring line

A pouring line and circulation technology, which is applied in the field of mechanical processing, can solve the problems of high labor intensity, low production efficiency, and large floor space, and achieve the effects of increasing work efficiency, high automation, and reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

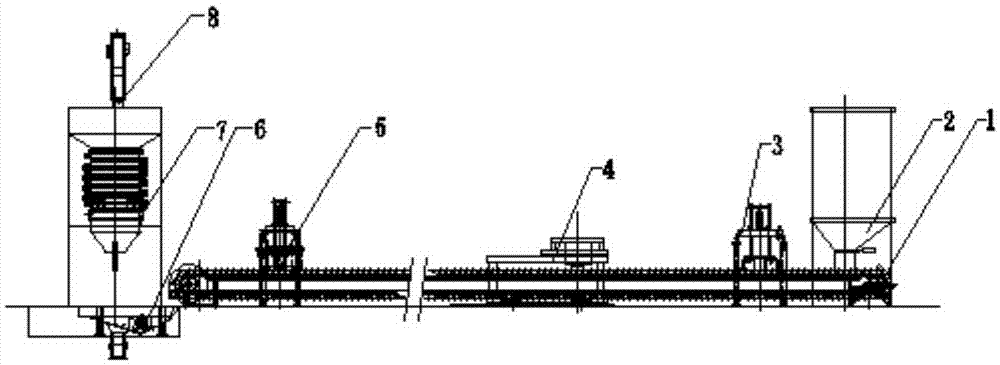

[0015] Such as figure 1 A circulating shell casting line is shown, which mainly includes: a slab conveying line 1, an upper sand storage mechanical device 2 installed at the beginning of the slab conveying line 1, and a mechanical device 2 installed at the end of the slat conveying line 1 The hoist 8; the scale plate conveying line 1 is sequentially installed with a shell type on-line mechanism 3, a bottom pouring machine 4 and a casting off-line mechanism 5 from the beginning to the end; the lower end of the hoist 8 is installed with a return Sand warehouse 7; the lower end of the sand return sand warehouse 7 and the lower end close to the end of the scale plate conveying line 1 are equipped with a vibrating separator 6 . Further, the bottom pouring pouring machine 4 is on the slab conveying line 1, and at the end of the middle part of the shell type on-line mechanism 3 and the casting off-line mechanism 5, the lower end is equipped with a rolling wheel; further, the describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com