Economical gantry type numerical control drilling machine control system based on PLC

A technology of control system and CNC drilling machine, applied in the field of machinery, can solve problems such as low production efficiency, unstable product quality, and inability to achieve popular use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

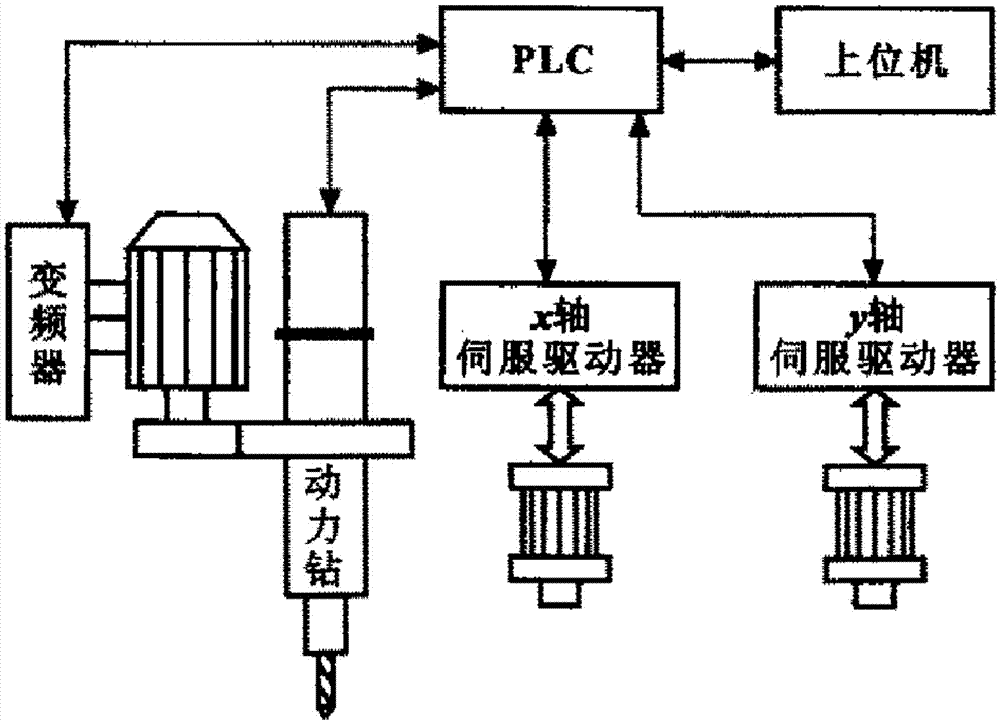

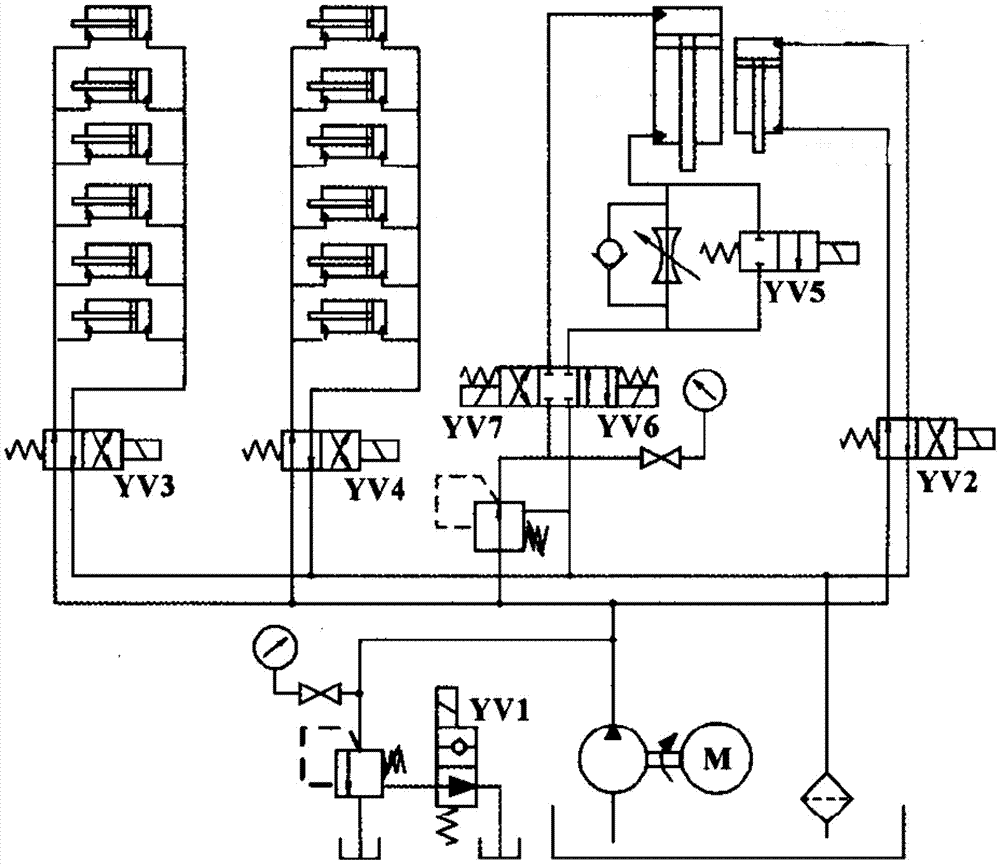

[0016] like figure 1 , The electrical control system mainly includes four parts, namely the configuration monitoring part of the upper computer, the PLC control part, the x-y axis servo positioning motion control part, the spindle frequency conversion speed regulator and the hydraulic power drilling feed part. During processing, the PLC and servo controller are used to control the movement, positioning and drilling of the CNC drilling machine in real time.

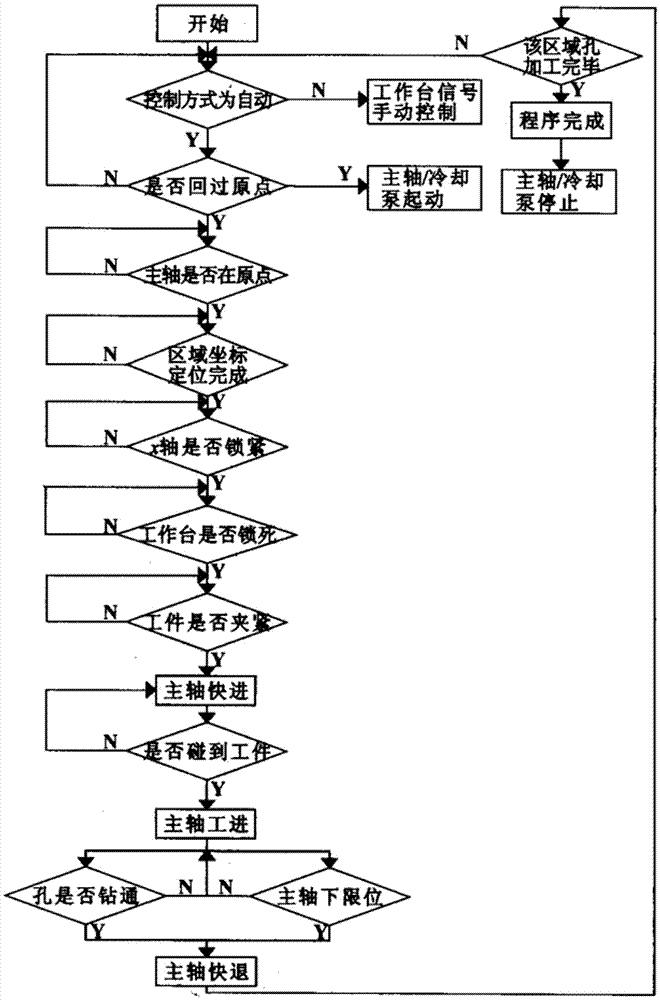

[0017] Using the host computer monitoring software can not only write the processing files for positioning drilling, but also realize the monitoring of PLC data transmission and CNC operation status through the operation of the screen in the configuration environment of the host computer. The programming function can be used to manually write the processing program. The operator only needs to input the size and hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com