A reaming clamping device

A clamping device and reaming technology, which is applied in the field of reaming processing, can solve the problems of reduced service life, non-straight hole wall generatrix, hole wall vibration lines, etc., and achieve long tool life, low hole wall roughness, and stable working conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

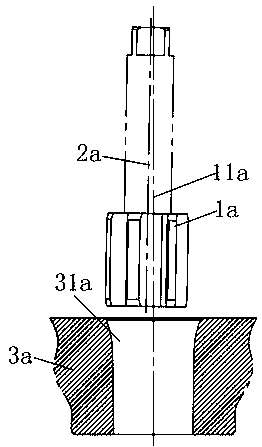

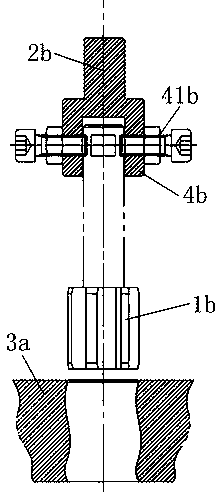

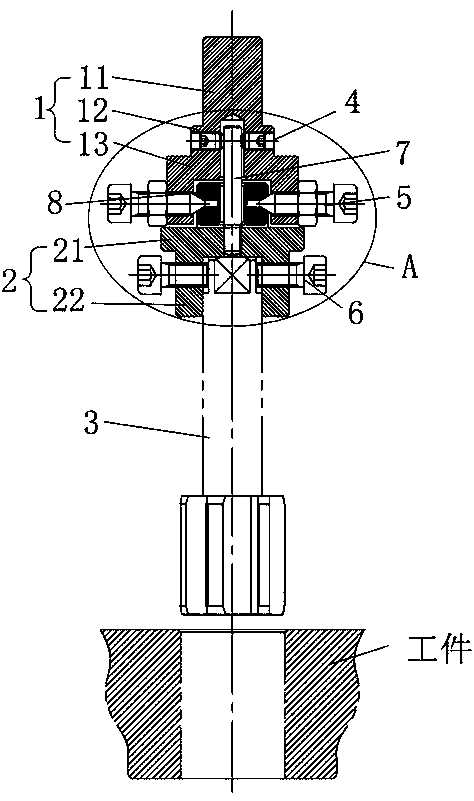

[0049] In the first embodiment, the first adjusting screw 4, the second adjusting screw 5 and the third adjusting screw 6 are all provided with three, and the three first adjusting screws 4 are evenly distributed along the circumferential direction of the fixing clamp handle 1, and the three The second adjusting screw 5 is evenly distributed along the circumferential direction of the clamp handle 1, and the three third adjusting screws 6 are evenly distributed along the circumferential direction of the tool mounting sleeve 2; when three are used, the adjustment can be realized more accurately, and the structure is simple.

[0050] The second embodiment, the first adjusting screw 4, the second adjusting screw 5 and the third adjusting screw 6 are all provided with four, and the four first adjusting screws 4 are evenly distributed along the circumferential direction of the fixing clamp handle 1, and the four A second adjusting screw 5 is evenly distributed along the circumferenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com