Rapid forming method used for manufacturing silkworm cocooning frames

A molding method and silkworm technology, applied in the directions of additive manufacturing, manufacturing tools, manufacturing auxiliary devices, etc., can solve the problems of unsuitability for mass production, poor reusability, low production efficiency, etc., to facilitate data processing work, ensure quality and Accuracy and the effect of ensuring molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

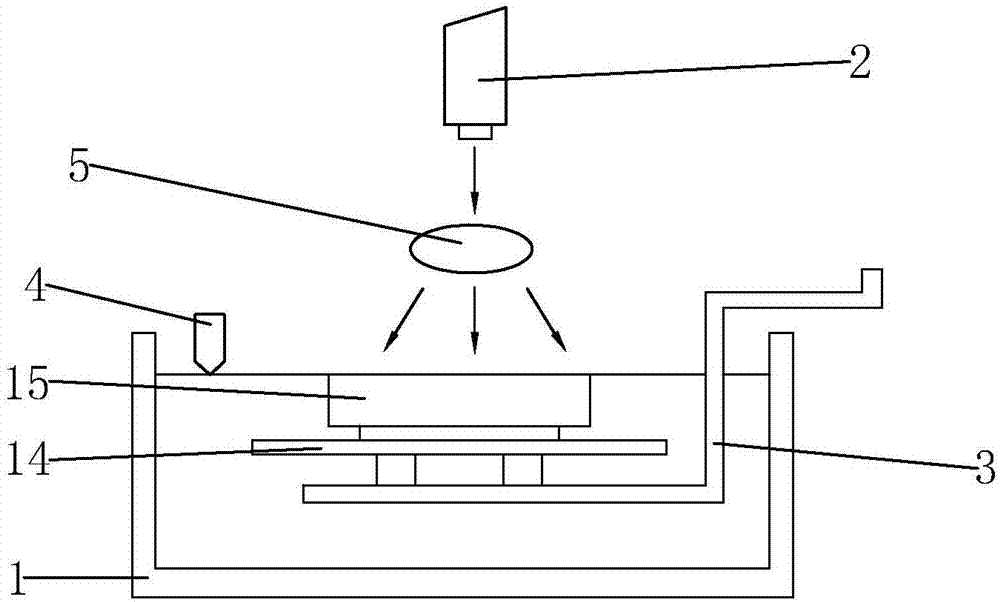

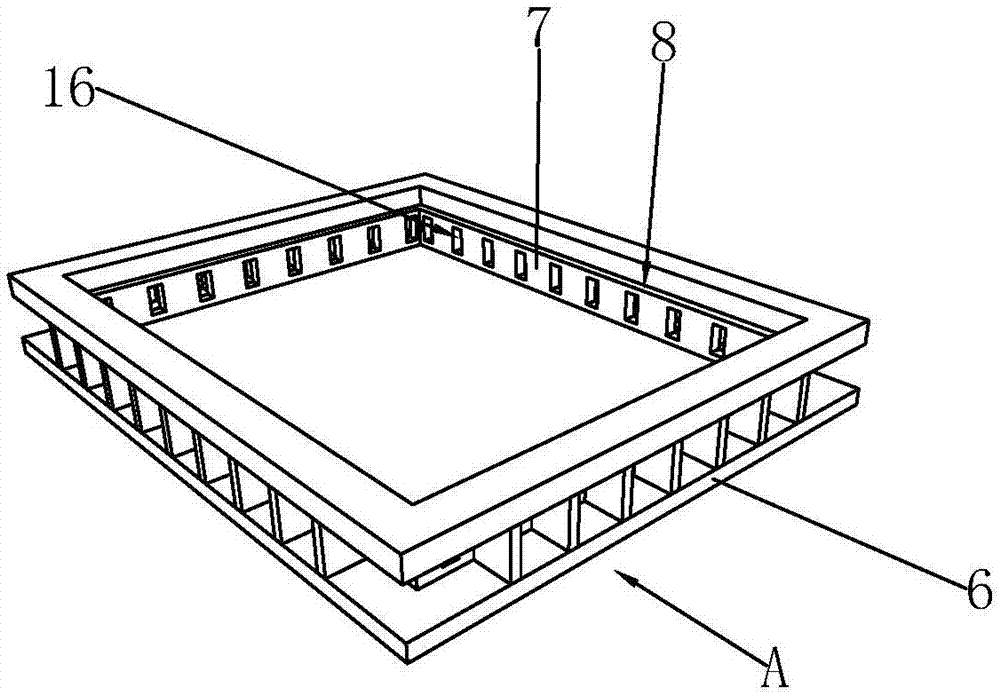

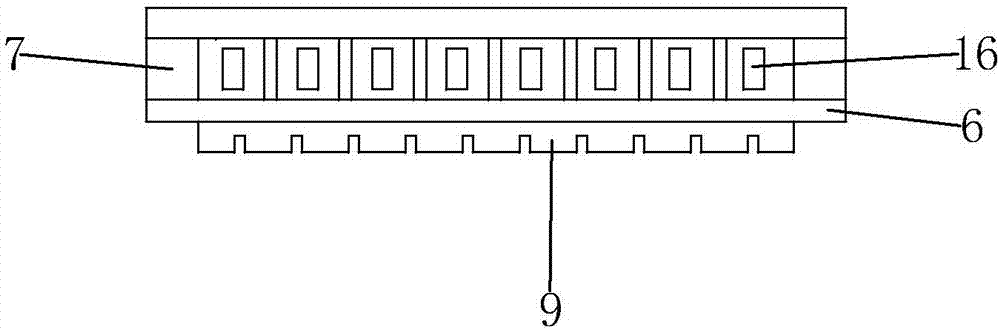

[0032] like Figure 1 to Figure 4 Shown, be the rapid prototyping method that the present invention is used to manufacture silkworm cocoon frame, comprises the following steps:

[0033] (a) Obtain cross-section information: Use computer-aided design software to build a three-dimensional solid model of silkworm frame molds, which is convenient for verifying the rationality, assemblability and aesthetics of product structures, and timely corrections to reduce losses if problems are found. Comparing with silkworm frame solid products, approximate the three-dimensional solid model and create STL format file. The STL format file is simple and practical. It is a standard interface file in the field of rapid prototyping. It uses a series of small triangular planes to approximate the original model. , each small triangle is described by 3 vertex coordinates and a normal vector, and the size of the triangle can be selected according to the accuracy requirements. Aiming at the free cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com