Cylinder body reciprocating type extruder used for 3D food printing

An extruder, reciprocating technology, applied in the field of cylinder reciprocating extruders, can solve problems such as unfavorable large-scale production, lack of stability and uniformity in efficiency, and difficult to achieve precise control, and achieve stable extrusion process. , the effect of high extrusion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

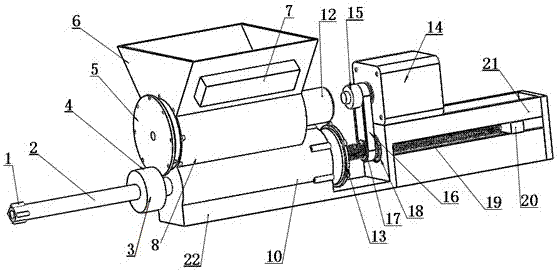

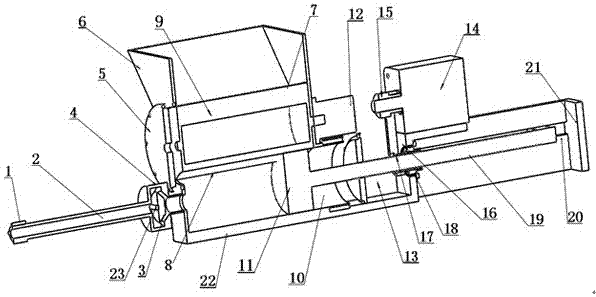

[0028] combined with Figure 1-3 As shown, a cylinder reciprocating extruder for 3D food printing includes a material hopper 6 for feeding, a material bin 8 that is airtightly connected to the discharge end of the material bin 6, and a material bin 8 that is connected with the material bin 6. 8. Airtightly connected cylinder body 10, one end of the cylinder body 10 is connected with a guide pipe 2 for discharging materials, and a piston for extruding materials into the guide pipe 2 is installed in the cylinder body 10 11. A control valve 9 for stirring and circulating materials is installed in the material bin 8. The control valve 9 is coaxially installed with the material bin 8 and driven by the first motor 12 arranged on the outer side of the material bin 8, so as to Used to stir the material and transfer the material flow into the cylinder 10;

[0029] The side of the piston 11 far away from the draft tube 2 is fixedly connected with a screw rod 19 for driving the piston 1...

Embodiment 2

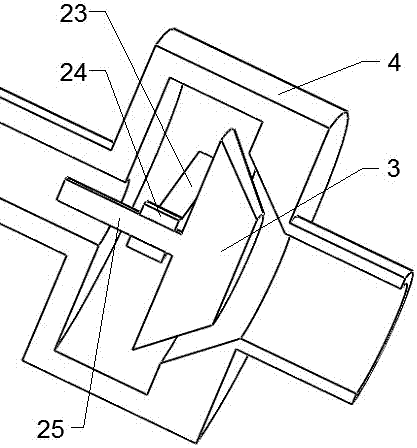

[0035] In order to further realize the present invention, this embodiment is based on Embodiment 1, by further setting an anti-backflow mechanism to prevent the reverse flow of materials, specifically adopting the following structure, combined with the attached Figure 1-3 As shown, an anti-backflow device is provided between the draft tube 2 and the cylinder body 10, and the anti-backflow device includes an anti-backflow housing 4 that is fixedly connected to the draft tube 2 and the cylinder body 10, and the anti-backflow housing 4. The limit column 23 is fixedly connected inside, and the end of the limit column 23 is fixedly connected with an annular sliding sleeve 24 with an opening. The anti-backflow valve plug 3 inside, the anti-backflow valve plug 3 realizes reciprocating movement in the anti-backflow valve plug 3 through the sliding rod 25 slidingly connected with the sliding sleeve 24 between the anti-backflow valve plug 3 and the anti-backflow housing 4 A spring in a...

Embodiment 3

[0037] In order to further realize the present invention, this embodiment is based on Embodiment 2. The lower part of the cylinder body 10 is provided with a cylinder body base 22, and the cylinder body base 22 extends toward one end of the screw rod 19 and is connected to The machine base that accommodates the screw mandrel 19 is fixedly connected, the second motor 14 is installed on the upper end of the machine base, and the end of the screw mandrel 19 that has an external thread is threaded with a screw nut 17, and the screw nut 17 is fixed A fixed bearing 18 nested on the side wall of the machine base is connected, and the screw nut 17 is drivingly connected with a drive wheel 15 detachably and fixedly connected to the output shaft of the second motor 14 through a transmission belt.

[0038] In this embodiment, the end of the screw rod 19 close to the base is provided with an anti-rotation column 20 that prevents the screw rod 19 from rotating with the screw nut 17, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com