Rapid production method of Chinese chestnut wine

A production method and technology for chestnut wine, applied in the field of rapid production of chestnut wine, can solve the problems of long production cycle, low production efficiency of chestnut hotels, and inability to fully utilize chestnuts, and achieve the effects of avoiding waste and shortening production time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below by means of specific embodiments:

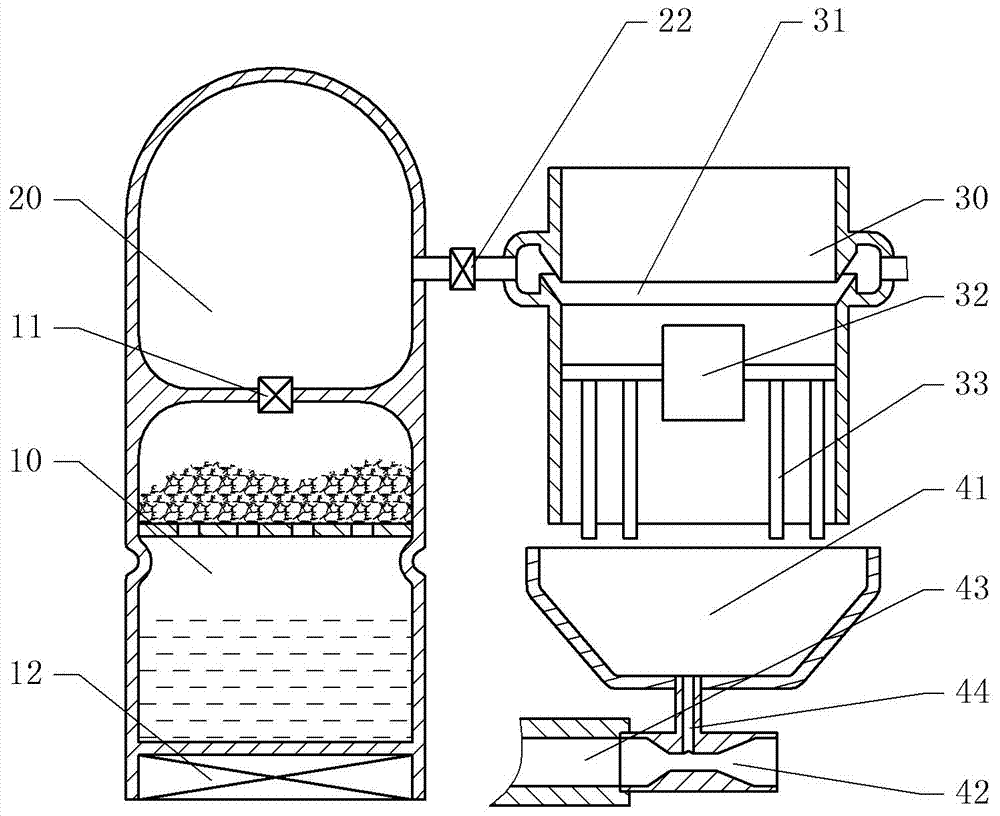

[0031] The reference numerals in the accompanying drawings of the description include: steam cylinder 10, check valve 11, heater 12, pressure steam tank 20, pressure control valve 22, air amplification cylinder 30, steam inlet 31, centrifugal separation cylinder 32, draft tube 33. Separation liquid collection hopper 41, mixing pipe 42, wine liquid inlet pipe 43, material suction pipe 44.

[0032] The rapid production method of chestnut wine in this embodiment includes using a chestnut wine production equipment to produce chestnut wine.

[0033] Such as figure 1 As shown, the chestnut wine production equipment includes a cooking device, a condensing device and a mixing device. The cooking device includes a heater 12, a steam drum 10 and a pressure steam tank 20;

[0034] The mixing device comprises a wine liquid inlet pipe 43, a mixing pipe 42, a separation liquid collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com