Installation method of pipeline bridge crossing canyon

An installation method and pipeline bridge technology, applied in bridges, bridge applications, bridge construction, etc., can solve problems such as difficult quality control, long construction period, and poor safety, and achieve the effects of easy quality control, shortened construction period, and reduced construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

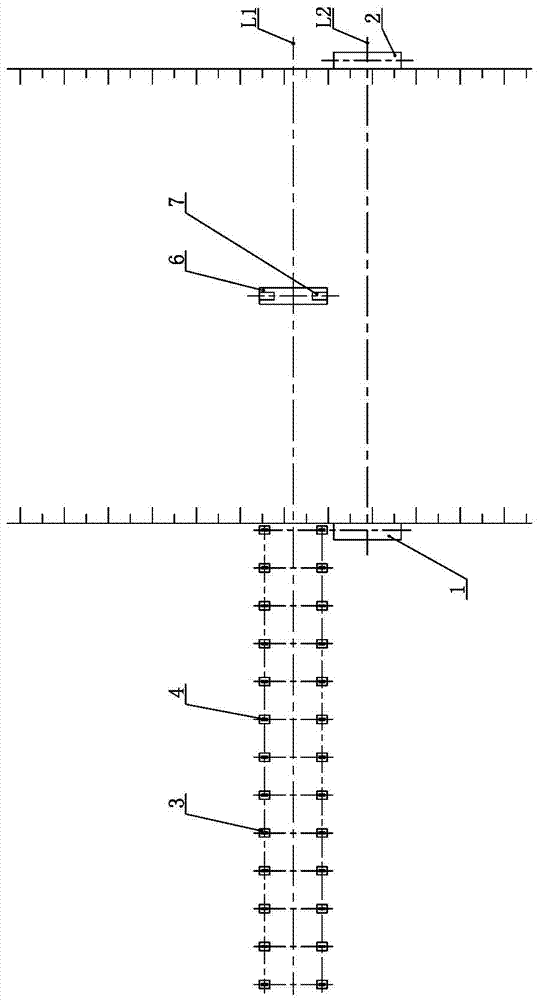

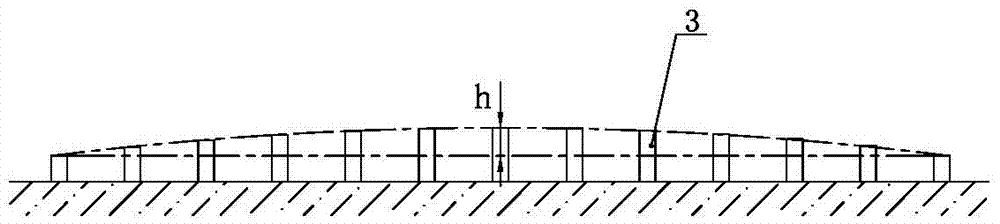

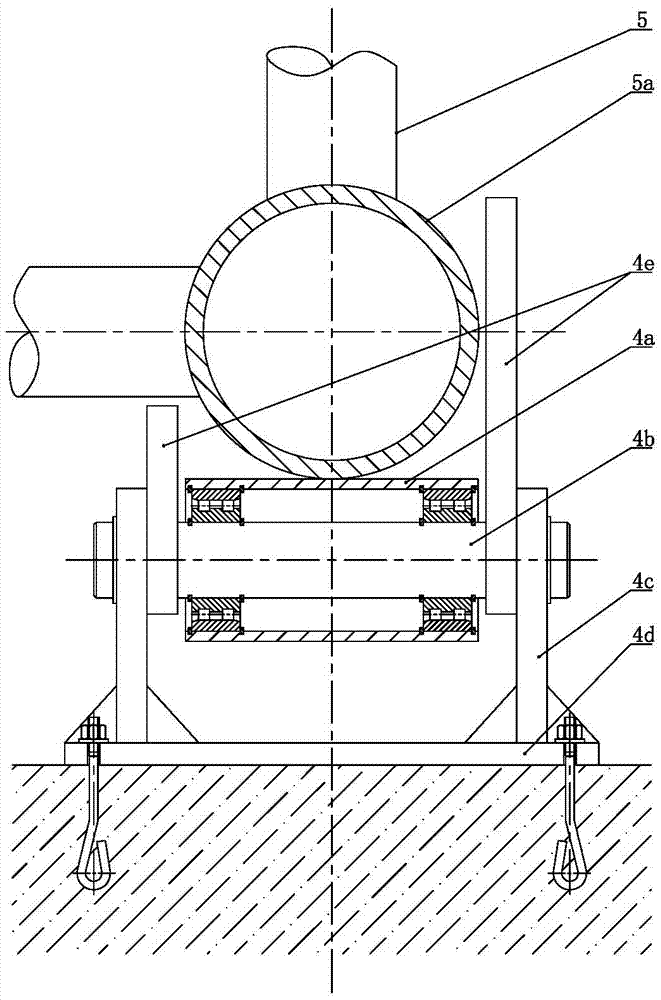

[0028] Such as Figure 1 to Figure 9 As shown, the installation method of the pipeline bridge crossing the canyon of the present invention includes the following steps in sequence: (1) Measure and set the line, determine the crossing line L1 on the canyon section, and determine the positions of the left pier 1 and the right pier 2 on the left and right banks of the canyon , The left pier 1 and right pier 2 are located on the crossing line L1; (2) the left pier 1 and the right pier 2 are poured on the left and right banks of the canyon, and the inherent pipeline bridge connection embedded parts are anchored on the top of the left pier 1 and right pier 2 respectively; (3) A transmission line L2 parallel to the crossover line L1 is set on the front or back side of the crossover line L1, and the center distance between the transmission line L2 and the crossover line L1 is 1.2 to 1.5 times the width of the pipeline bridge 5; ⑷ in the canyon The pipeline bridge 5 is made on the left b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com