Reciprocating impact part of multistage protection sealing telescopic sleeve

A telescopic shaft sleeve and impact part technology, applied in cutting machinery, earth-moving drilling, slitting machinery, etc., can solve problems such as increased power consumption, leakage of lubricating and cooling medium, poor sealing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

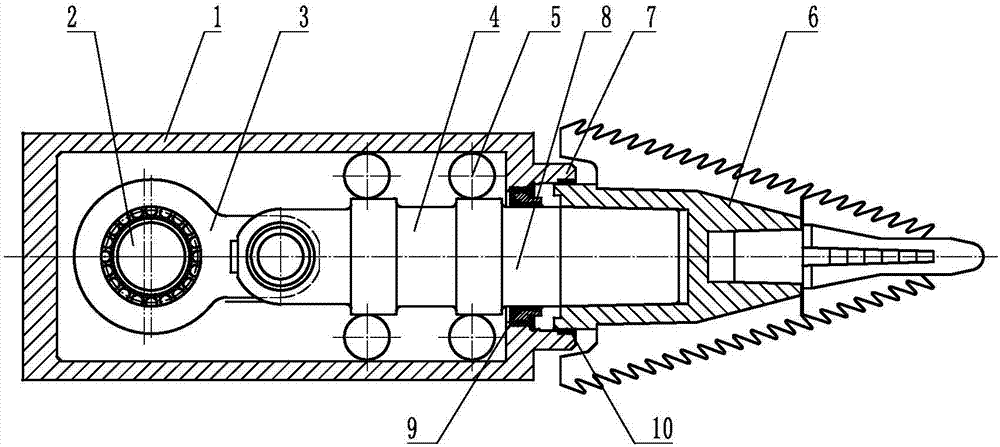

[0044] Such as figure 1 As shown, a reciprocating impact part of a multi-stage protective seal telescopic sleeve includes a multi-stage protective guide shaft casing 1, a crankshaft 2, a connecting rod 3, a guide impact member 4, a guide member 5 and a main reciprocating tooth 6, etc., and the multi-stage The guide shaft housing 1 supports the guide piece 5, etc. The guide piece 5 supports the guide impact piece 4 and guides the guide impact piece 4, the crankshaft 2 is connected with the connecting rod 3, the crankshaft 2 drives the connecting rod 3, and the connecting rod 3 drives the guide impact piece 4 Reciprocating impact, crankshaft 2, connecting rod 3, guide impact piece 4, guide piece 5, etc. are arranged in the multi-stage protective guide shaft box 1, one end of the guide impact piece 4 protrudes outside the multi-stage guide shaft box 1, and the guide impact The multi-stage protective guide shaft casing 1 at the extension end of the part 4 is provided with a multi-...

Embodiment 2

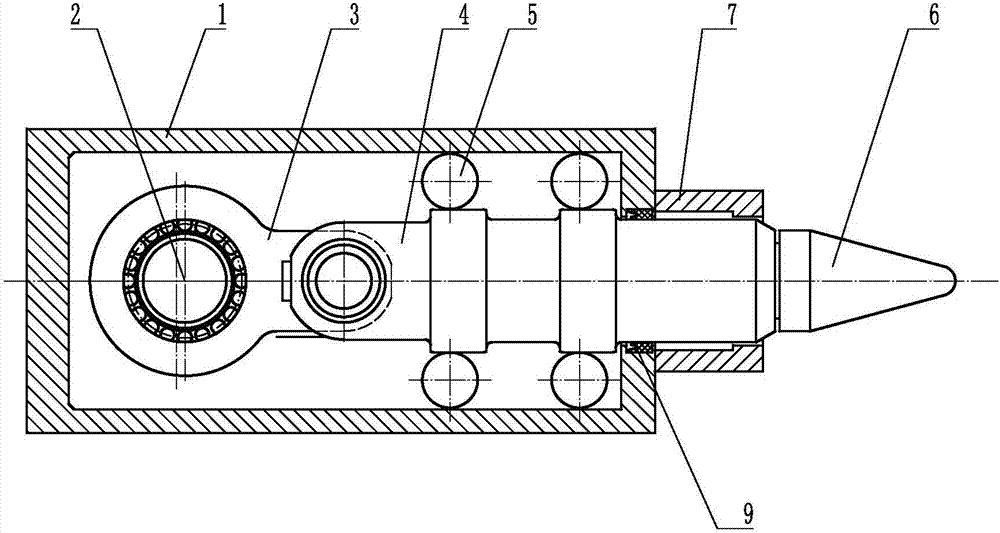

[0047] Such as figure 2 As shown, a reciprocating impact part of a multi-stage protective seal telescopic sleeve includes a multi-stage protective guide shaft casing 1, a crankshaft 2, a connecting rod 3, a guide impact member 4, a guide member 5 and a main reciprocating tooth 6, etc., and the multi-stage The guide shaft housing 1 supports the guide piece 5, etc. The guide piece 5 supports the guide impact piece 4 and guides the guide impact piece 4, the crankshaft 2 is connected with the connecting rod 3, the crankshaft 2 drives the connecting rod 3, and the connecting rod 3 drives the guide impact piece 4 Reciprocating impact, crankshaft 2, connecting rod 3, guide impact piece 4, guide piece 5, etc. are arranged in the multi-stage protective guide shaft box 1, one end of the guide impact piece 4 protrudes outside the multi-stage guide shaft box 1, and the guide impact The multi-stage protective guide shaft casing 1 at the extension end of the part 4 is provided with a multi...

Embodiment 3

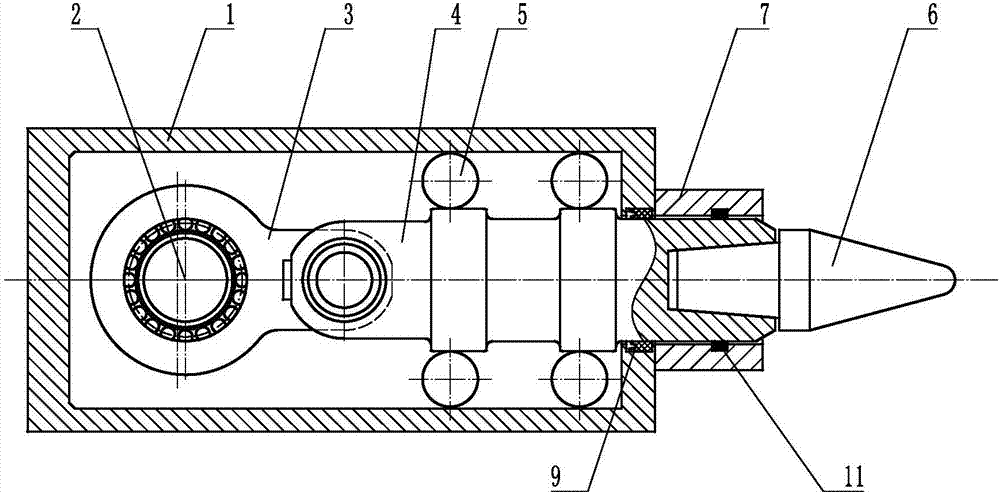

[0050] Such as image 3 As shown, a reciprocating impact part of a multi-stage protective seal telescopic sleeve includes a multi-stage protective guide shaft casing 1, a crankshaft 2, a connecting rod 3, a guide impact member 4, a guide member 5 and a main reciprocating tooth 6, etc., and the multi-stage The guide shaft casing 1 supports the guide piece 5, the guide piece 5 supports the guide impact piece 4 and guides the guide impact piece 4, the crankshaft 2 is connected with the connecting rod 3, the crankshaft 2 drives the connecting rod 3, and the connecting rod 3 drives the guide impact piece 4 to reciprocate Impact, crankshaft 2, connecting rod 3, guide impact piece 4, guide piece 5, etc. are arranged in the multi-stage protection guide shaft box body 1, one end of the guide impact piece 4 protrudes outside the multi-stage protection guide shaft box body 1, and the guide impact piece 4 The multi-stage protective guide shaft casing 1 at the protruding end is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com