Tee-joint switching device for boiler denitration

A three-way and denitration technology, applied in the chemical industry, can solve the problems of boiler negative pressure fluctuation, increase the frame height, and stop the furnace, and achieve the effect of reducing the construction workload, avoiding erosion and wear, and saving investment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

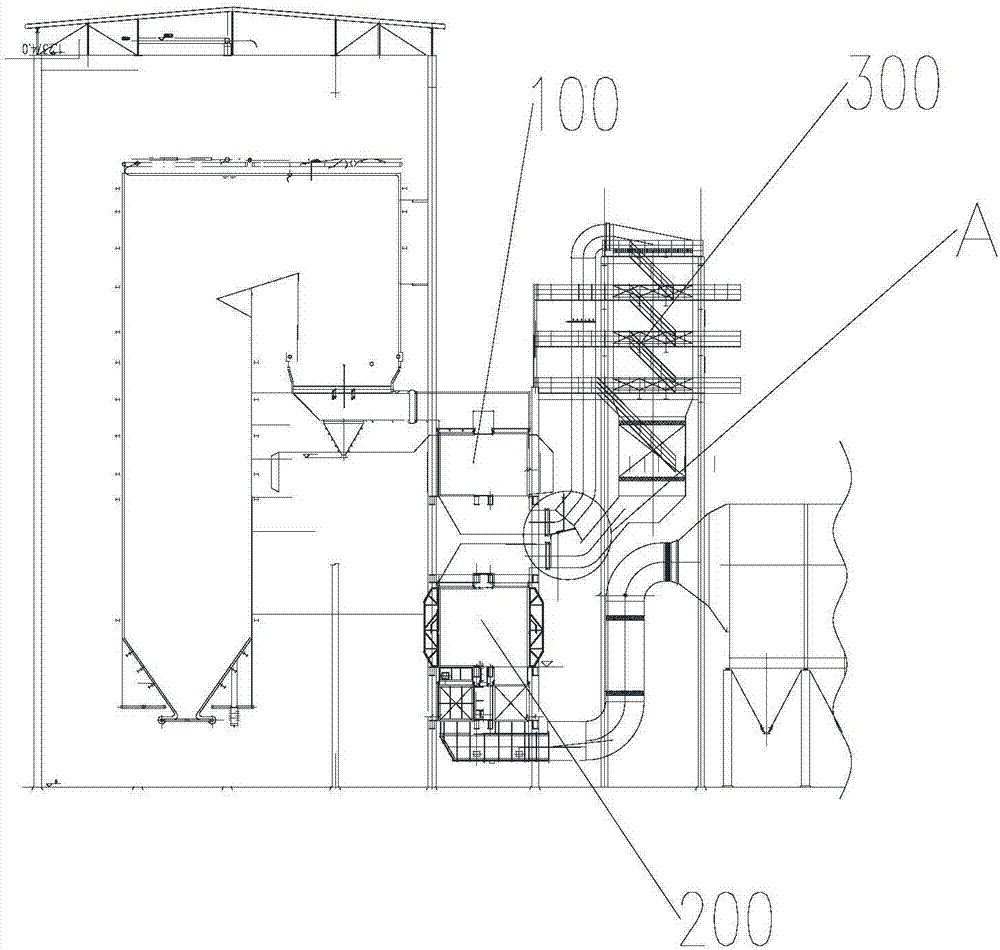

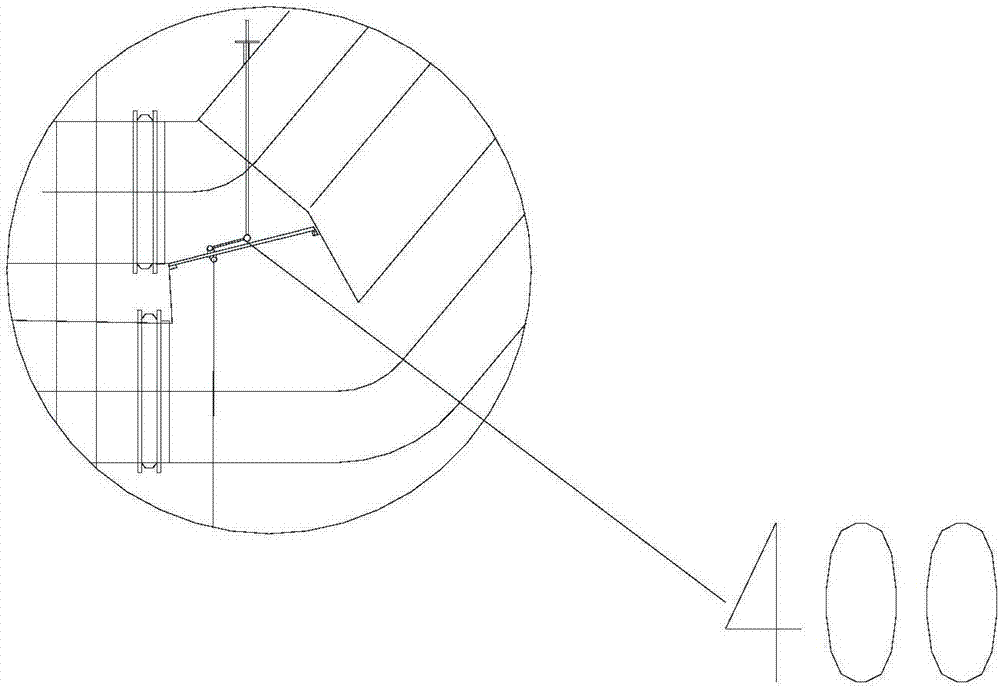

[0028] figure 1 It is a schematic diagram of a boiler using a three-way switching device in an embodiment of the present invention. figure 2 yes figure 1 Enlarged view of A. combine figure 1 and figure 2 It can be seen that the three-way switching device 400 for boiler denitration of the present invention is located between the denitration reactor 300 , the low-temperature economizer or air preheater 200 , and the high-temperature economizer or air preheater 100 .

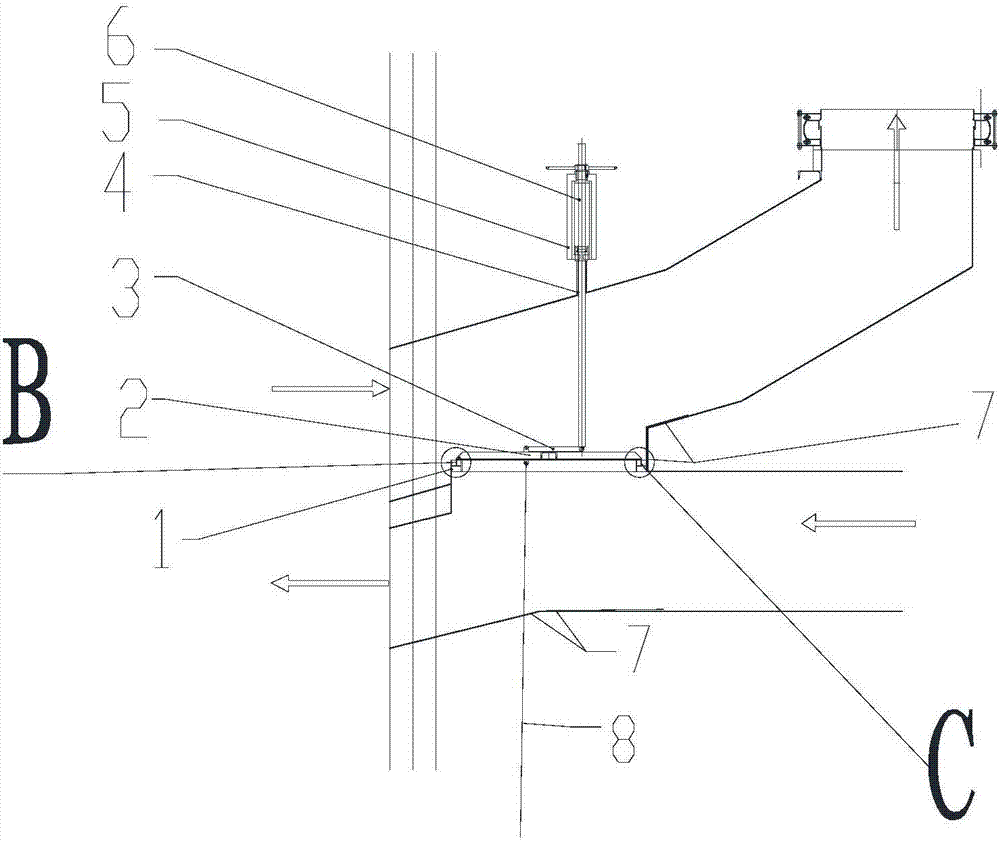

[0029] image 3 It is a structural schematic diagram of the three-way switching device when the sealing baffle is closed in another embodiment of the present invention. Such as image 3 As shown, the boiler denitrification tee switching device 400 of this embodiment includes a frame 1 and a sealing baffle 2 .

[0030] The frame 1 is located at the connection between the inlet and outlet of the flue of the denitration reactor, the flue of the low-temperature economizer or the air preheater, and the flue of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com