Layered optimization method for multistage multi-spraying-pipe ejector

An optimization method and ejector technology, applied in the field of ejection, can solve the problems that the ejector design method cannot be considered, the ejection efficiency is low, and the prediction accuracy is not high, so as to save development costs, increase ejection efficiency, reduce The effect of deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

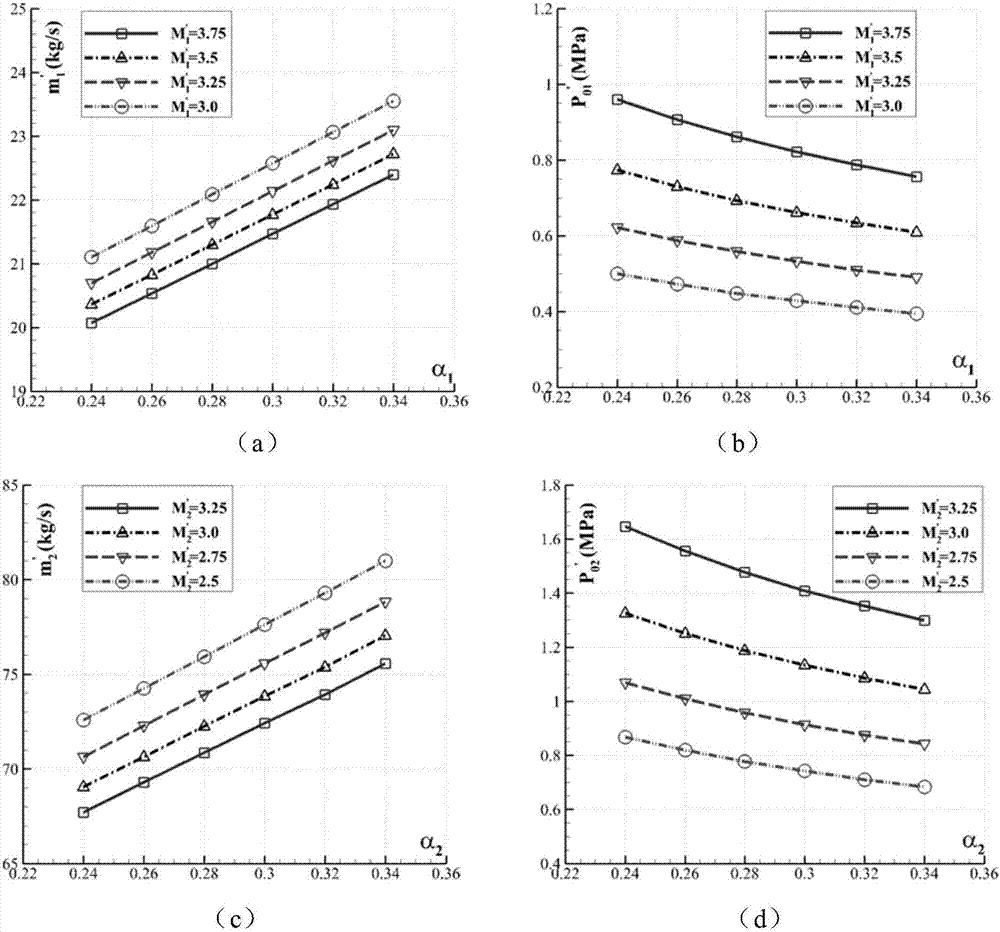

[0074] Design conditions: a hypersonic wind tunnel operates with a Mach number of 5-8, the total pressure of the front chamber is 0.8-8.5MPa, the total temperature is 375-750K, and the outlet diameter of the wind tunnel nozzle is 100mm. It is required to design an ejector that meets the operating conditions of the wind tunnel.

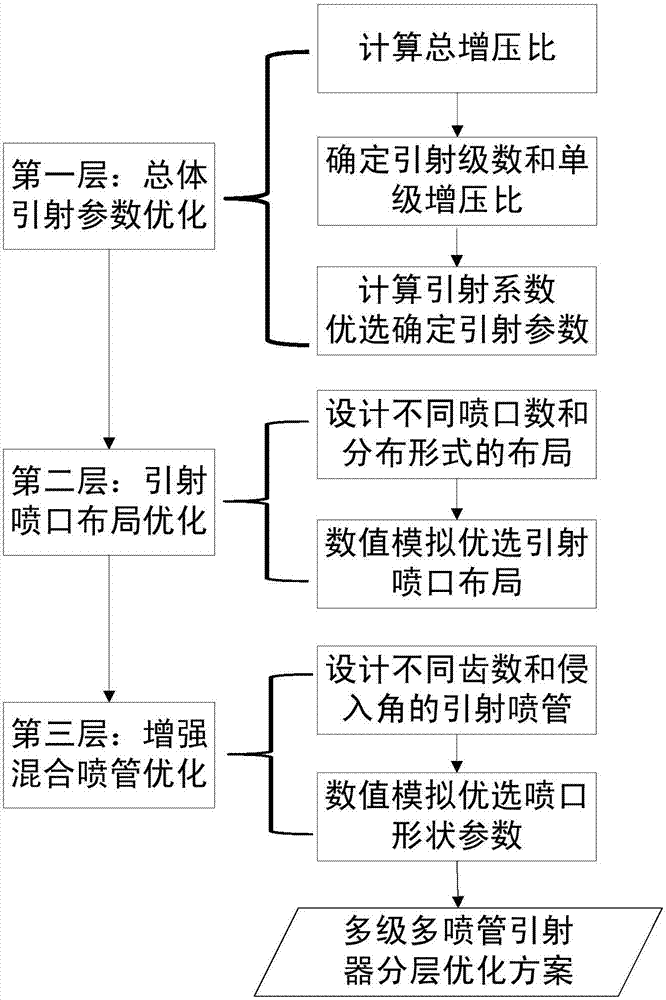

[0075] (1) Optimization of the overall parameters of the ejector

[0076] (1.1) Calculate the total boost ratio

[0077] When the wind tunnel Mach number M=5-8, the total pressure of the ejected airflow P 01 It can be estimated according to the formula: P 01 =P 0 σ s / 1.8, where P 0 is the total pressure in the antechamber of the wind tunnel, σ s is the ratio of the total pressure after the normal shock wave to the total pressure before the normal shock wave at the corresponding wind tunnel Mach number, and 1.8 is an empirical coefficient considering various losses. Calculate the total pressure of the ejected airflow and the flow rate of the ejec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com