Integrated modeling method for global analysis of power plant boiler steel structure

A modeling method and technology for power plant boilers, applied in the field of steel structures in structural engineering, can solve problems such as amplifying the effect of horizontal earthquakes, reducing the rationality and economy of structural design results, and inability to accurately reflect the size and distribution of boiler horizontal forces. Achieve the effect of simple mechanical model, high calculation efficiency and easy modeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

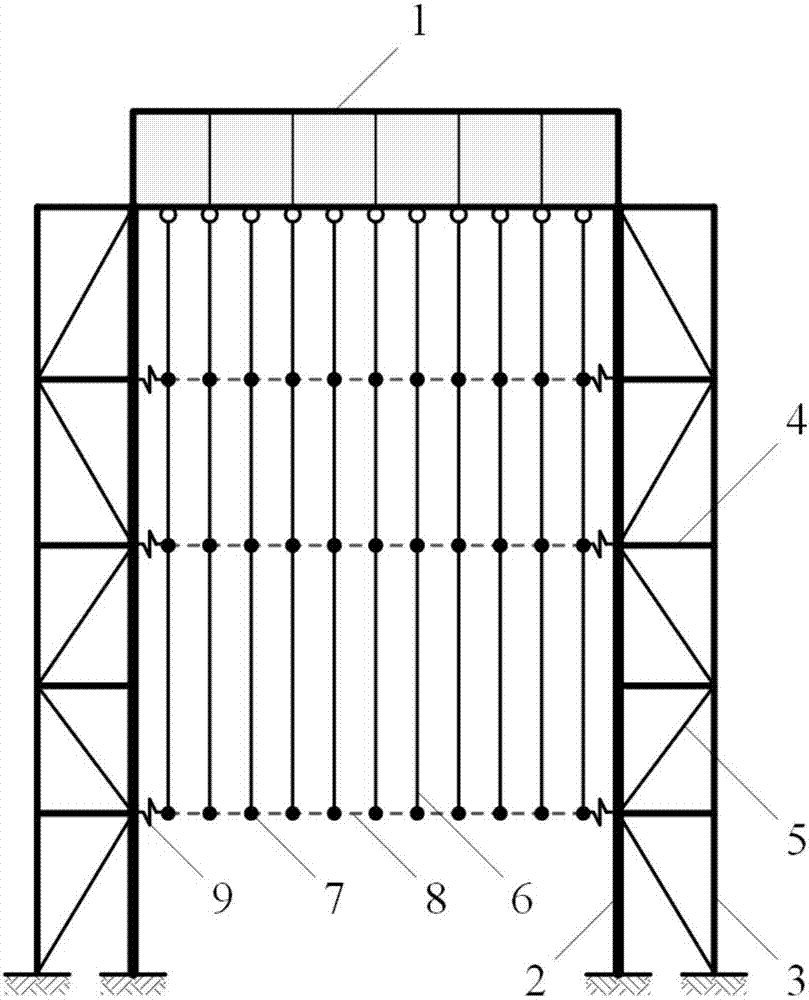

[0020] figure 1 Schematic diagram of the calculation model for the integrated modeling method for the overall analysis of the steel structure of the utility boiler. The integrated calculation model is divided into two parts: the frame structure model and the simplified mechanical model of the boiler body. The frame structure model is composed of a large plate beam 1, an inner steel column 2, an outer steel column 3, a steel beam 4 and a vertical support 5. The simplified mechanical model of the boiler body is mainly composed of rigid tie rods 6 and mass points 7 .

[0021] According to the design conditions and related geometric dimensions and section types, use the beam element model to establish the inner steel column 2, outer steel column 3, steel beam 4 and vertical support 5 in the frame model, and use the beam element or shell element or soli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com