Predicting method of material grain size distribution in ball-milling process

A particle size distribution and material technology, applied in neural learning methods, biological neural network models, special data processing applications, etc., can solve problems such as complex dynamic characteristics of the process, time-varying and complex ore sources, and inability to guarantee long-term prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0016] Aiming at the shortcomings of insufficient prediction of particle size distribution of ball milling materials in the prior art and inability to correct the prediction results on-line, the present invention proposes a method for predicting particle size distribution of ball milling materials.

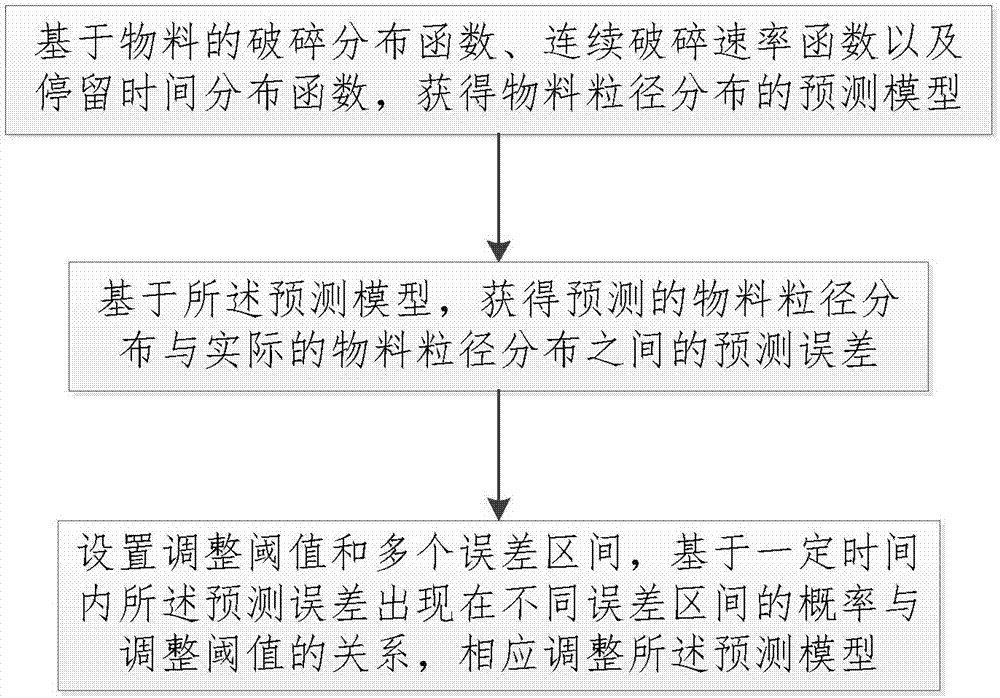

[0017] figure 1 A schematic flow chart of a method for predicting material particle size distribution in a ball milling process according to an embodiment of the present invention is shown, as can be seen from the figure, including:

[0018] S1. Based on the crushing distribution function of the material, the continuous crushing rate function and the residence time distributi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com