Three-dimensional reconstruction method for defective blade tip of aircraft engine compressor blade

An aero-engine and three-dimensional reconstruction technology, which is applied in the field of robot vision, can solve the problems of not considering the similarity of curves and surfaces, poor extension smoothness, etc., and achieve the effects of easy programming, improved smoothness, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

[0037] The invention provides a three-dimensional reconstruction method (abbreviation method) of aeroengine compressor blade tip defect, it is characterized in that concrete steps are as follows:

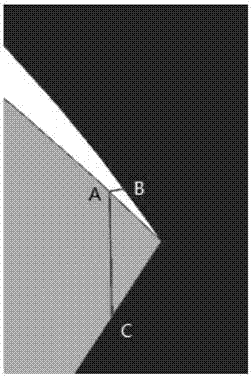

[0038] 1. Optical three-dimensional measurement: select the repairable worn blade, use the optical three-dimensional measurement method to measure the repairable worn blade, and obtain the point cloud of the blade (see figure 1 ); figure 1 Shown in is the point cloud of the data points obtained from the three-dimensional measurement and displayed under the Geomagic Studio software; the specific method is to project sinusoidal fringes to the repairable worn blade to obtain a new relationship between phase and height h'=f(Δφ') and The previousl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com