A method and device for removing glue from a heat sink of a semiconductor device

A semiconductor and cooling plate technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as low efficiency, damage to semiconductor components, and failure to clean the cooling plate, so as to save costs and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical problems solved by the present invention, the technical solutions adopted and the technical effects achieved clearer, the technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

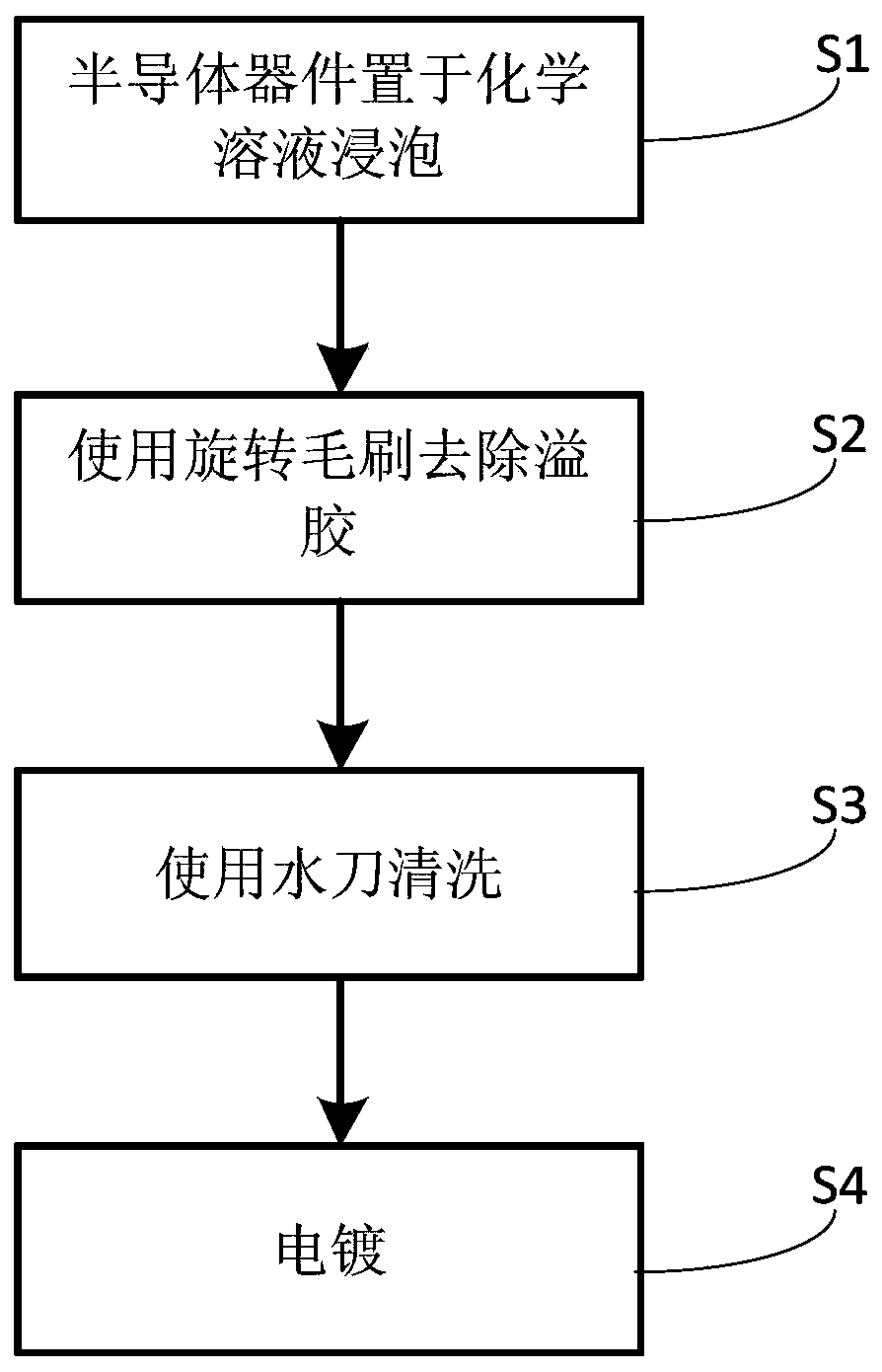

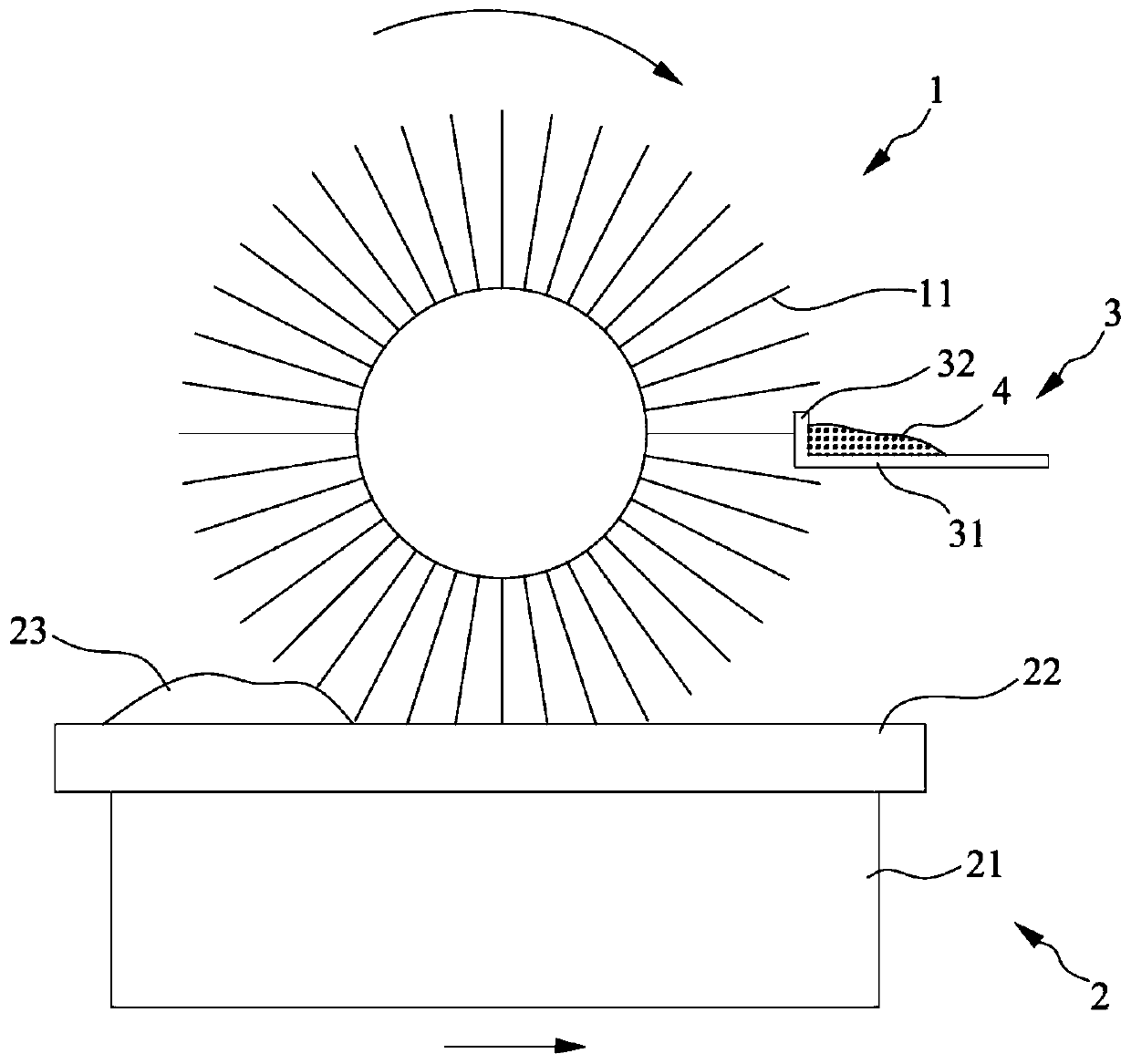

[0029] like figure 2 As shown, when the semiconductor device 2 is packaged by injection molding, the injection molding packaging layer 21 is formed under the heat dissipation plate 22, and the overflow glue 23 may be produced on the heat dissipation plate 22, and sometimes the overflow glue 23 is very serious, and the high-pressure water is used after soaking and softening in a chemical solution. Knives also cannot be removed cleanly, so if figure 1 As shown, the invention provides a kind of deglue method of the radiator plate of semiconductor device, comprises the following steps:

[0030] S1: Soak the semiconductor device 2 in a chemical solution to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com