Chemical laser embedded control equipment log processing system and method

An embedded control and laser technology, applied in the transmission system, digital transmission system, electrical components, etc., can solve the problems that cannot satisfy the fault diagnosis record analysis function of chemical lasers, the log record form is single, and the log content is limited. Status positioning analysis and diagnosis processing, which is beneficial to daily maintenance and reduces the effect of risk and safety cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described in detail below in conjunction with the examples.

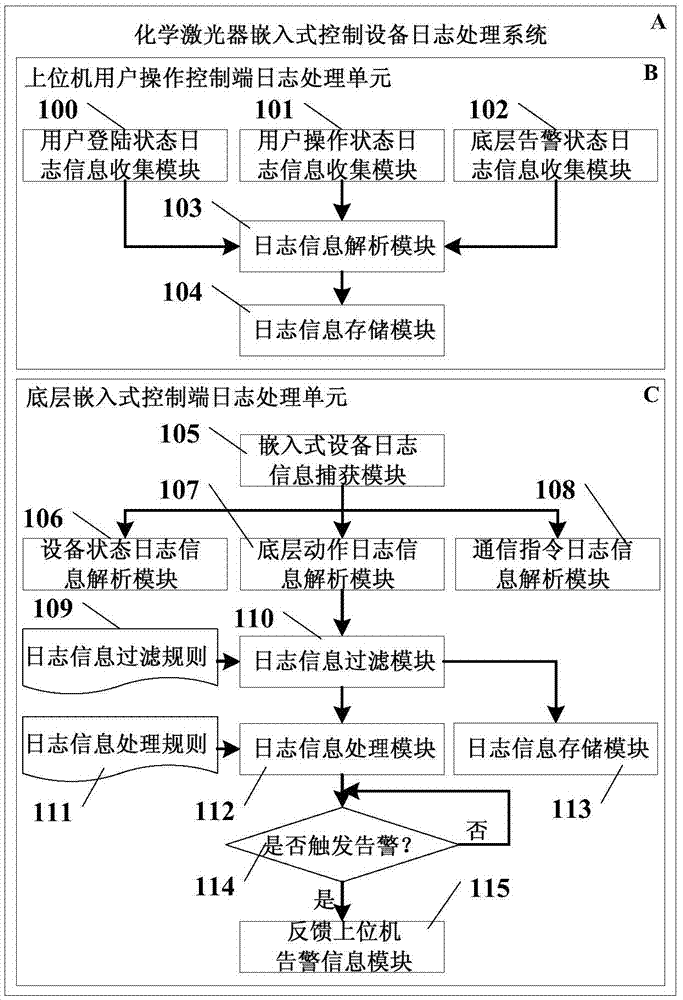

[0050] A log processing method capable of capturing, collecting and analyzing work logs of a chemical laser embedded control device. The log processing method of the chemical laser embedded control device of the present invention comprises a log processing unit of the user operation control terminal of the upper computer of the chemical laser embedded control device and a bottom embedded control terminal log processing unit.

[0051] The log processing unit of the user operation control terminal of the upper computer is set in the upper computer, including a user login status log information collection module, a user operation status log information collection module, and an underlying alarm status log information collection module, as well as a log information processing module and a log information storage module .

[0052] The underlying embedded control terminal log ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com