Wiring substrate

A technology for wiring substrates and substrates, which is applied to circuit substrate materials, printed circuit components, electrical components, etc., and can solve problems such as cracks, narrow installation area of radiators, and size constraints.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Next, modes for implementing the present invention will be described.

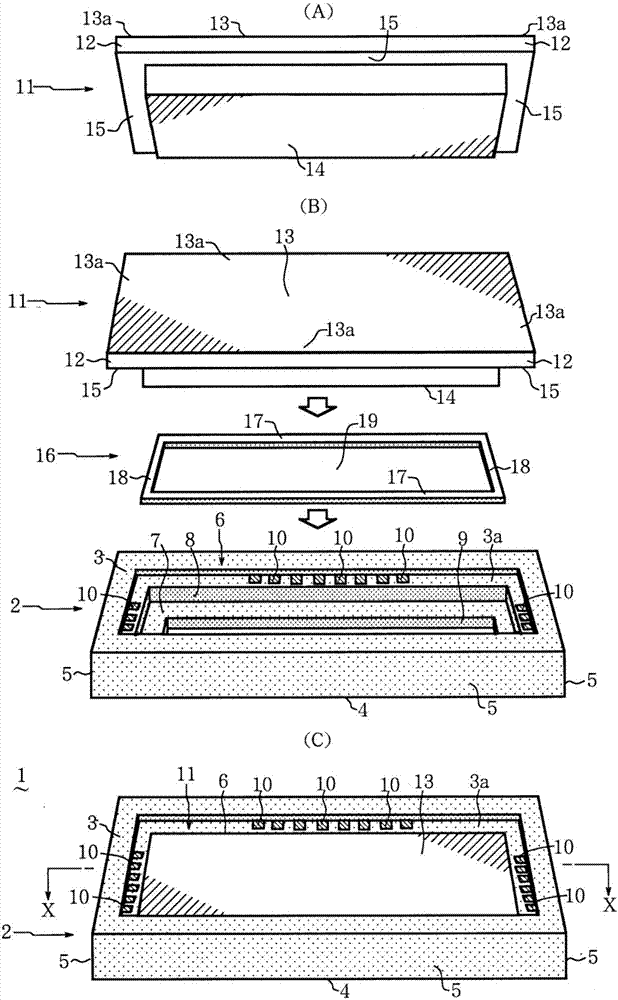

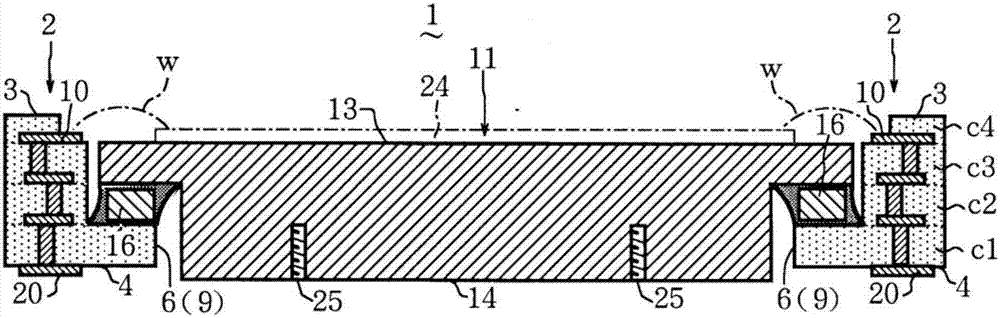

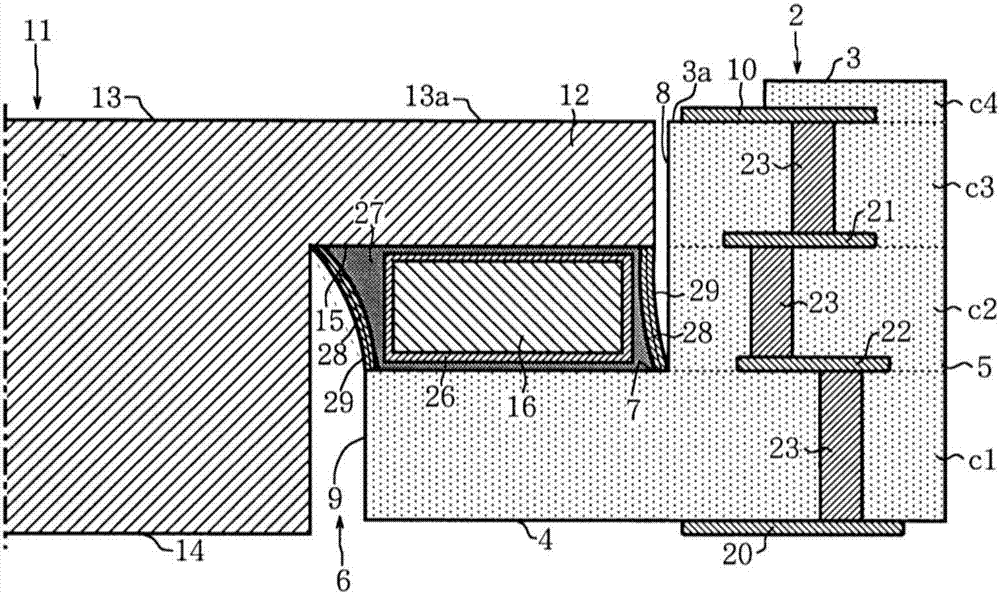

[0059] figure 1 (A) is a perspective view of the heat sink 11 used in the wiring board 1 of the present invention as viewed from the back surface 14 side, figure 1 (B) is an exploded perspective view of the wiring board 1 of the present invention, and is a perspective view of the heat sink 11 as viewed from the surface 13 side, a perspective view of the stress buffer ring 16 as viewed from the surface side, and a perspective view of the substrate main body 2 as viewed from the surface 3. Stereoscopic view from side view.

[0060] Such as figure 1 of (A), figure 1 As shown in (B), the above-mentioned heat sink 11 has: a surface 13 and a back surface 14, which are rectangular (rectangular) when viewed from above; In the shape of a rectangular frame. The surface 13a of the flange 12 is on the same plane as the above-mentioned surface 13, and the opposite side (back side 14 side) of the flange 12 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com