Visual follow detection gluing system

A detection system and gluing technology, applied in the field of visual follow-up inspection gluing system, can solve the problems of construction without considering complex working environment, unfavorable application of complex working environment, affecting the quality of finished vehicles off-line, etc., so as to avoid transformation and buffering. Vigorous swing, the effect of improved automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

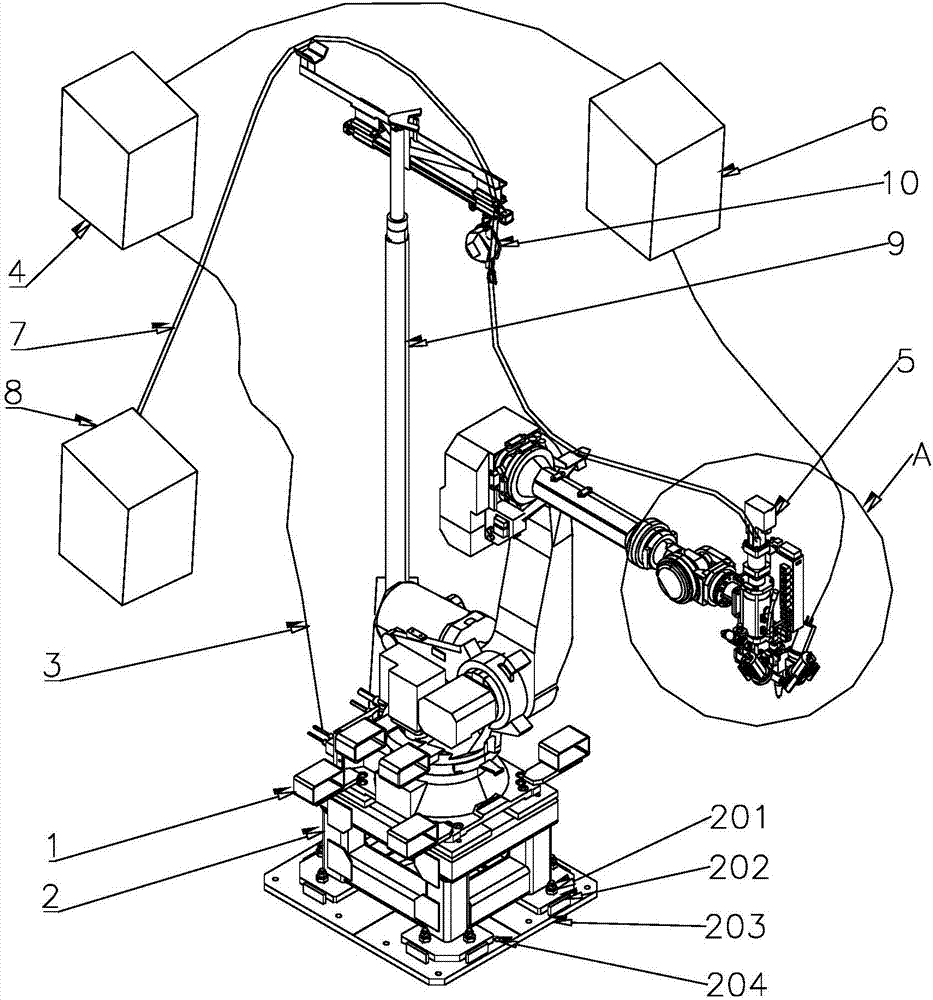

[0024] Such as figure 1 , 2 As shown, the visual following detection gluing system includes a gluing robot 1, the gluing robot 1 is installed on the robot stand 2, the gluing robot 1 is connected to the robot control cabinet 4 through the cable 3, and the robot stand 2 is square Table-shaped, the four corners of the bottom are precisely fixed on the platform fixing plate 203 by bolts 201 and stoppers 202 respectively, and the platform fixing plate 203 is fixed on the ground by anchor bolts 204 .

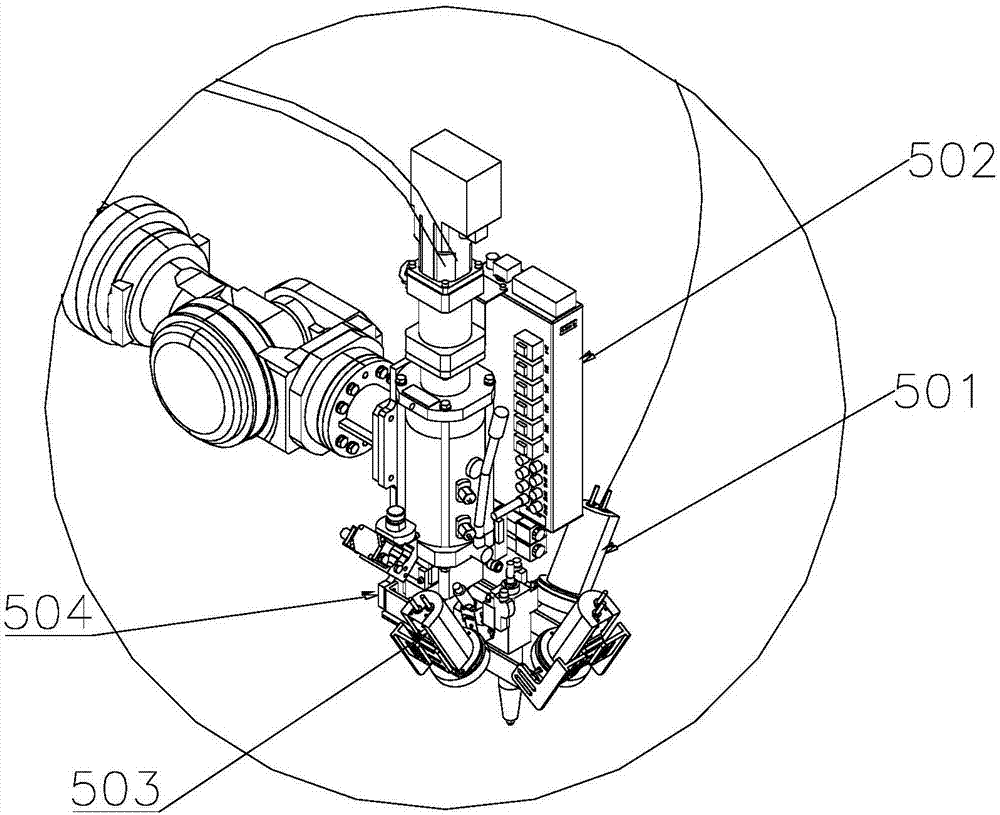

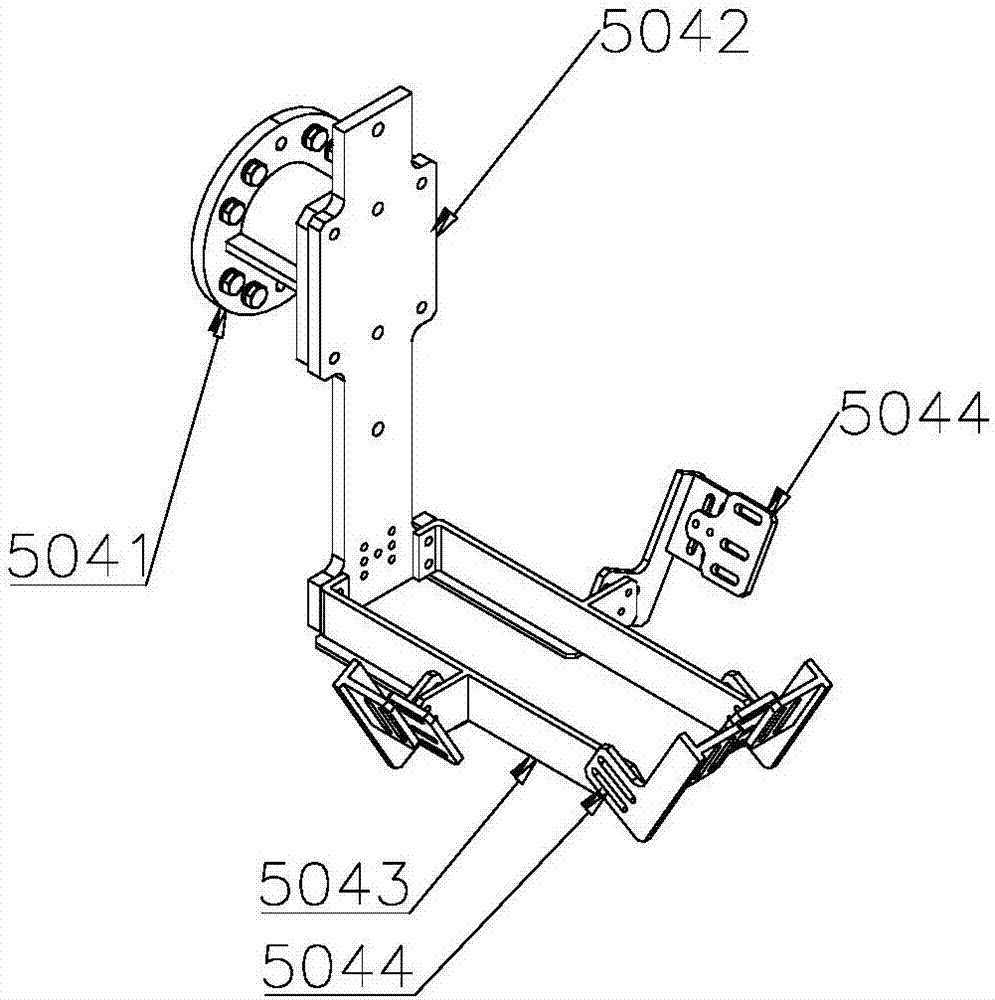

[0025] The end of the gluing robot 1 is equipped with a visual glue gun 5. The visual glue gun 5 includes a visual follow-up detection system 501 and a glue gun 502. The visual follow-up detection system 501 is connected to the vision control cabinet 6 through a cable. 7 is connected to the glue pump 8. The visua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com