Peanut oil and its preparation method

A technology for peanut oil and peanuts, which is applied in the direction of producing fat, fat oil/fat production, etc., can solve the problems of large differences in the direction of peanut oil flavor and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] Therefore, the preparation method of peanut oil of the present invention and the method for reducing the denaturation rate of peanut protein in peanut oil production process generally comprise:

[0061] (1) Preparation of peanut pulp, comprising roasting peanuts at 70-110°C for 8-18 minutes, then adding water to beat the roasted peanuts into pulp to obtain peanut pulp;

[0062] (2) Enzymolysis, including adding protease, vegetable oil and reducing sugar to the peanut pulp obtained in step (1), performing enzymolysis to obtain an enzymolysis product; and

[0063] (3) Heating, including heat-treating the enzymatic hydrolysis product obtained in step (2) at a temperature of 160-180°C.

[0064] 1. Preparation of peanut pulp

[0065] There are no special restrictions on the source and variety of peanuts. All kinds of peanuts used in the art to prepare peanut oil can be used in the present invention. Usually, peanuts are roasted at 70-110°C, preferably 75-105°C, such as 80...

Embodiment 1

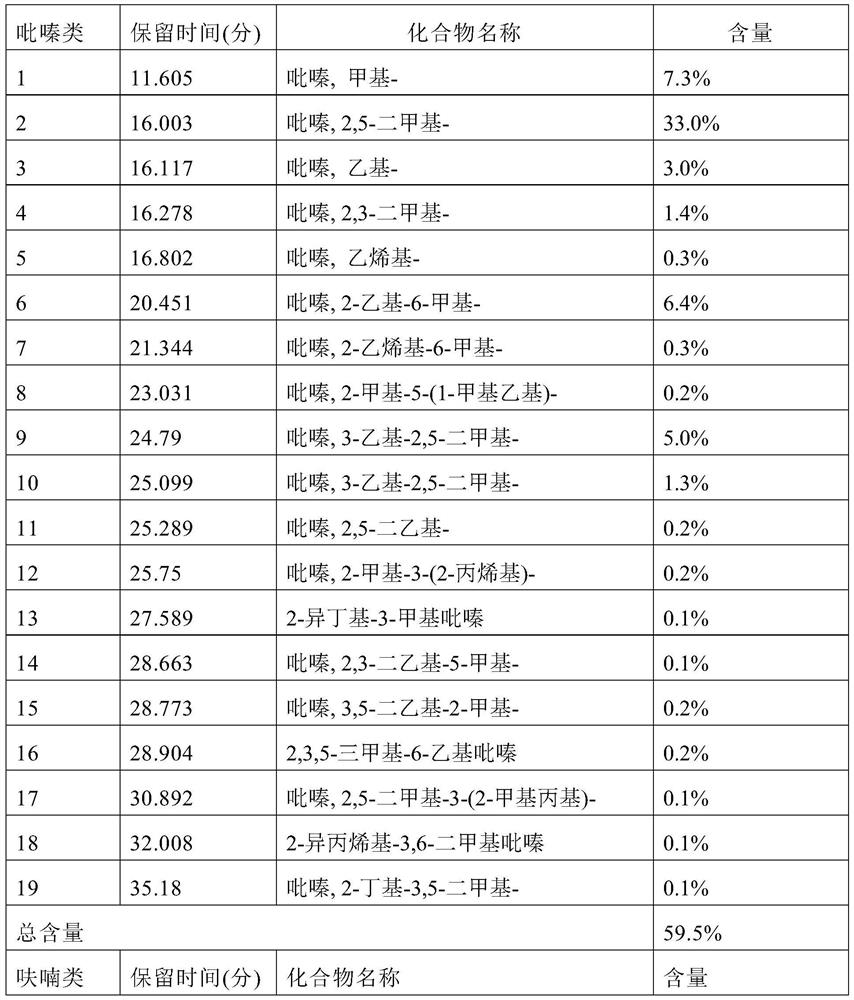

[0104] Example 1: Take 500g of peanuts, bake at 70°C for 15 minutes, add 500g of water, grind for 5 minutes, add 1000g of pH=7.3 phosphate buffer solution, 10g of protease (flavor protease 1000L: neutral protease 0.8L: alkaline protease 2.4L= 3:2:1), 2000g of refined peanut oil, 15g of glucose, enzymolysis at 50°C for 2h, then directly raise the temperature to 170°C for 30min. The tap water was cooled to 18°C and centrifuged to prepare the fragrant peanut oil.

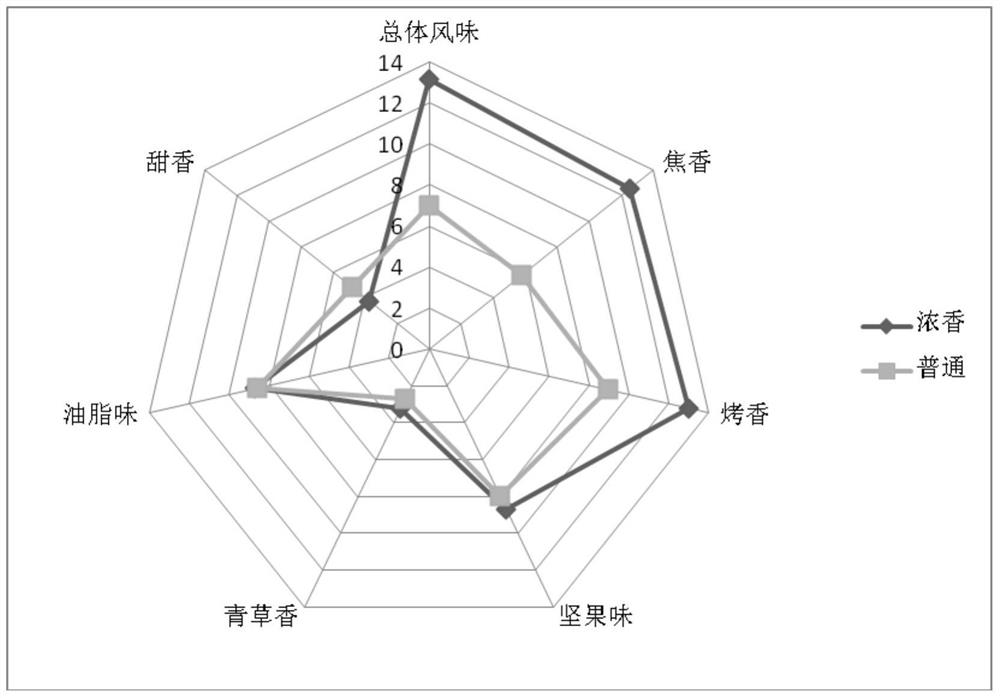

[0105] The prepared peanut oil was subjected to sensory evaluation, and the results showed that the aroma was natural, plump and pleasant, and the aroma was strong.

Embodiment 2

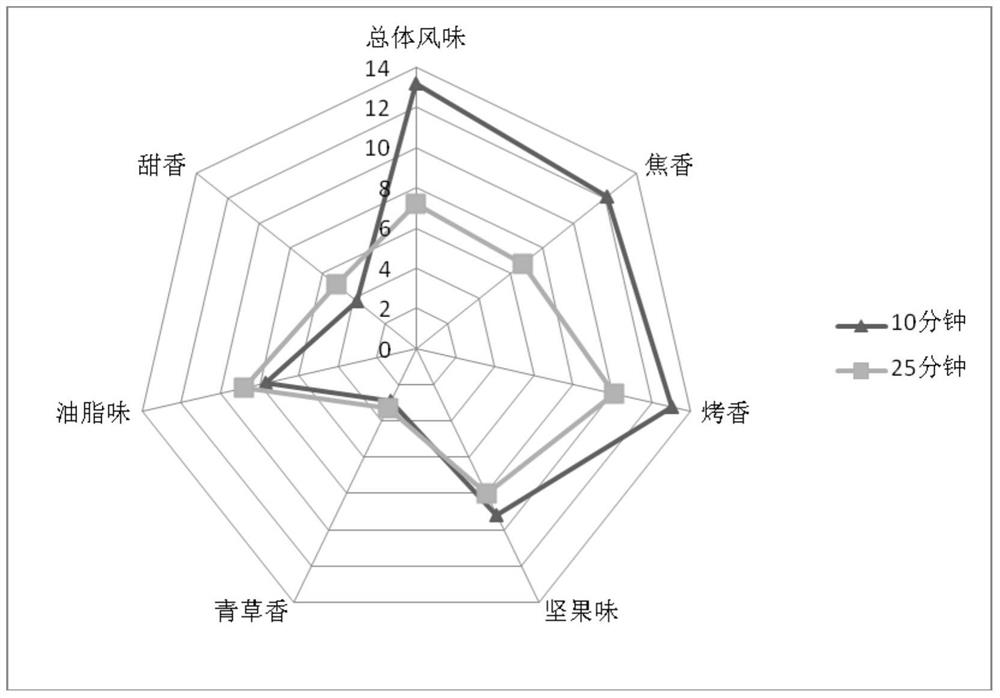

[0106] Example 2: Take 500g of peanuts, bake at 100°C for 10min, add 500g of water, refine the pulp for 5min, add 1000g of pH=7.3 phosphate buffer solution, 10g of protease (flavor protease 1000L: neutral protease 0.8L: alkaline protease 2.4L= 3:2:1), 2000g of refined peanut oil, 15g of glucose, enzymolysis at 50°C for 4h, then directly heated to 170°C for 30min. The tap water was cooled to 18°C and centrifuged to prepare the fragrant peanut oil.

[0107] The prepared peanut oil was subjected to sensory evaluation, and the results showed that the aroma was natural, plump and pleasant, and the aroma was strong.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com