Preparation method of catalytic reactant with efficient catalysis of thermal reaction

A production method and technology of reactants, which are applied in chemical instruments and methods, catalyst activation/preparation, combustion methods, etc., can solve the problems of low oxidation efficiency and thermal reaction efficiency cannot be effectively or better greatly improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make it easier and simpler to understand the other features and advantages of the present invention and the effects achieved, the features and advantages of the present invention will be described in detail with reference to the accompanying drawings, and the following embodiments will be further described in detail viewpoints of the present invention, but not to limit the scope of the present invention in any way.

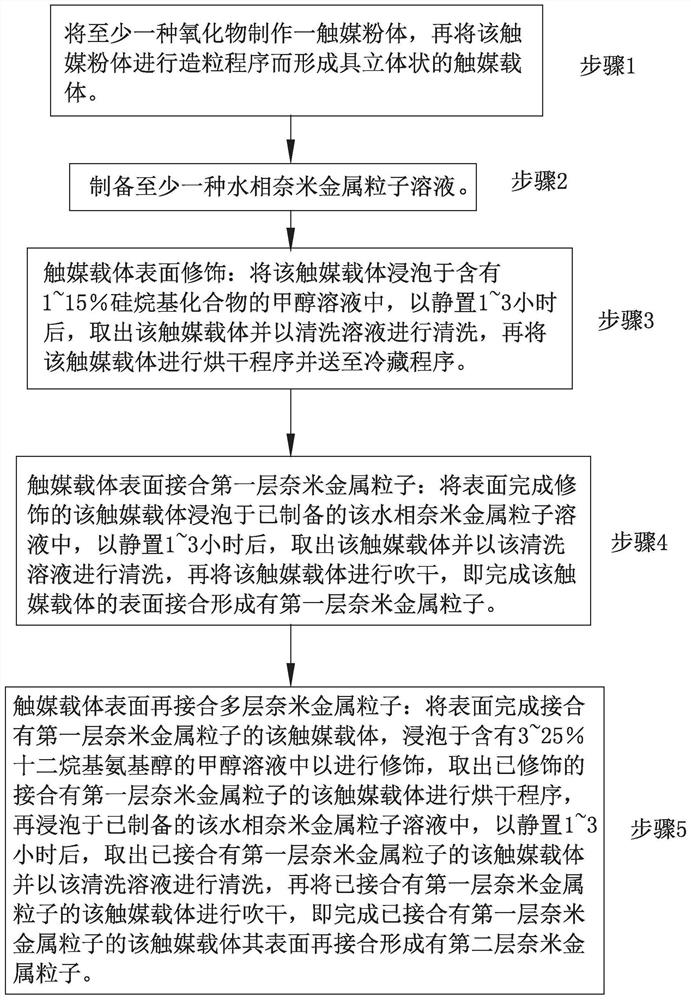

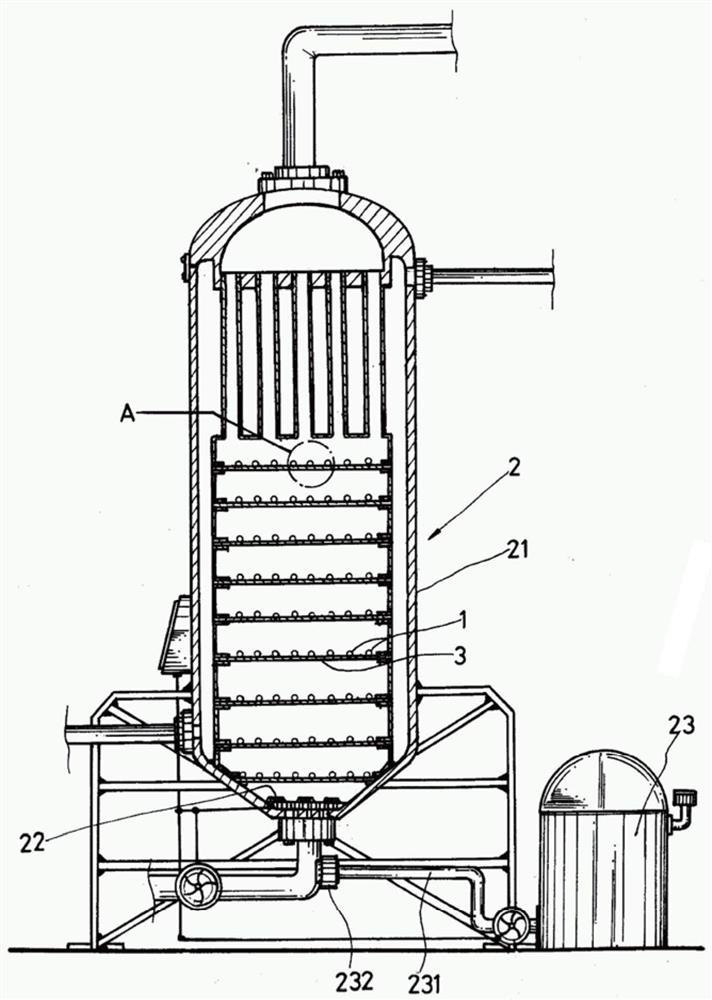

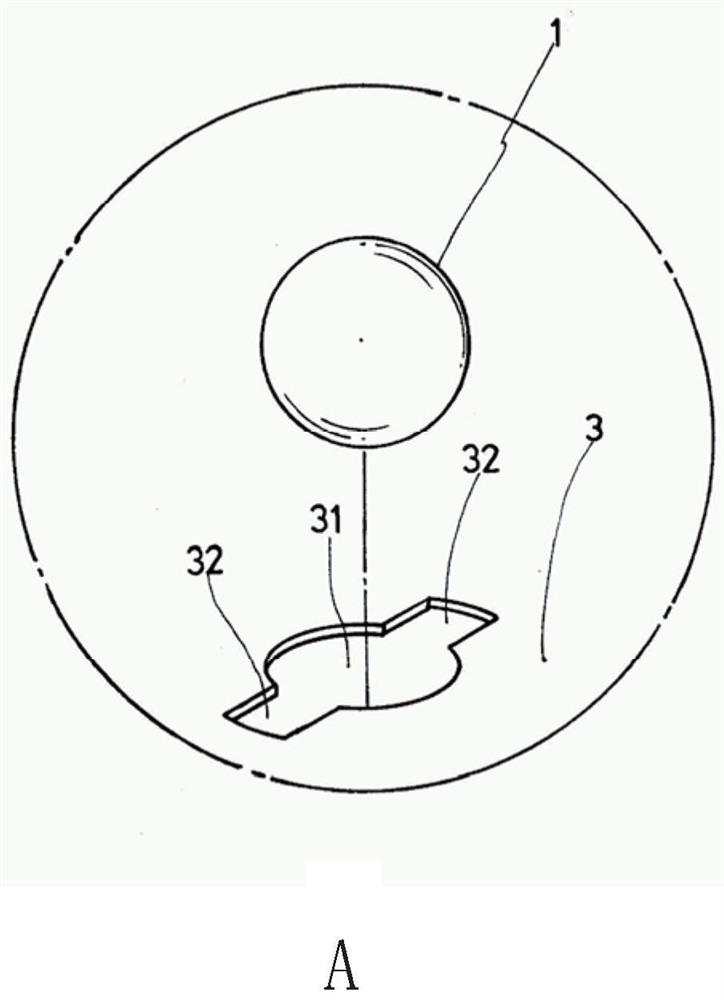

[0040] Please see first figure 1 , figure 2 and image 3 As shown, the present invention discloses a method for preparing a catalyst reactant with high-efficiency catalysis for thermal reaction. The catalyst reactant 1 is especially applied to a catalytic gas-phase reaction system 2, so as to enhance the catalytic gas-phase reaction system 2 and its The catalytic activity of fuel combustion reaction set inside, its preparation method of described catalyst reactant 1 comprises:

[0041] Step 1: Catalyst carrier preparation: At least one oxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com