EGR cooler

An EGR cooler and cooling water technology, applied in the field of engine coolers and EGR coolers, can solve the problems such as the inability to guarantee the brazing dimensional accuracy, the large volume of the EGR cooler, and the leakage at the welding point, so as to ensure the leak-proofness and improve the Production efficiency and the effect of forced heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

[0024]

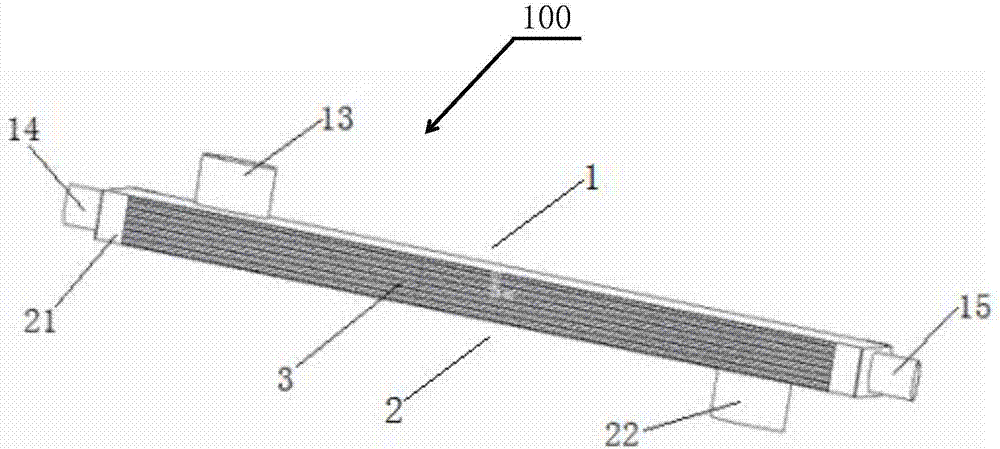

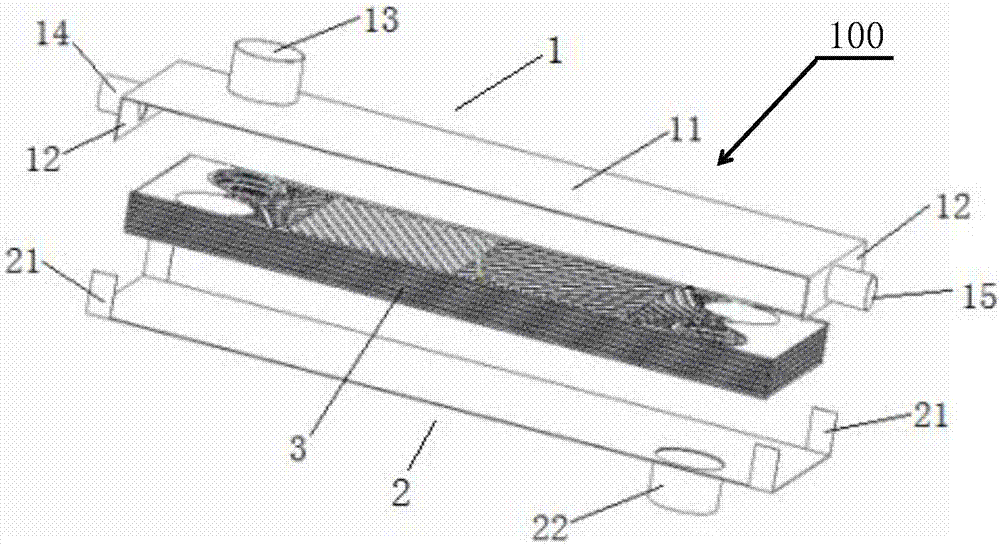

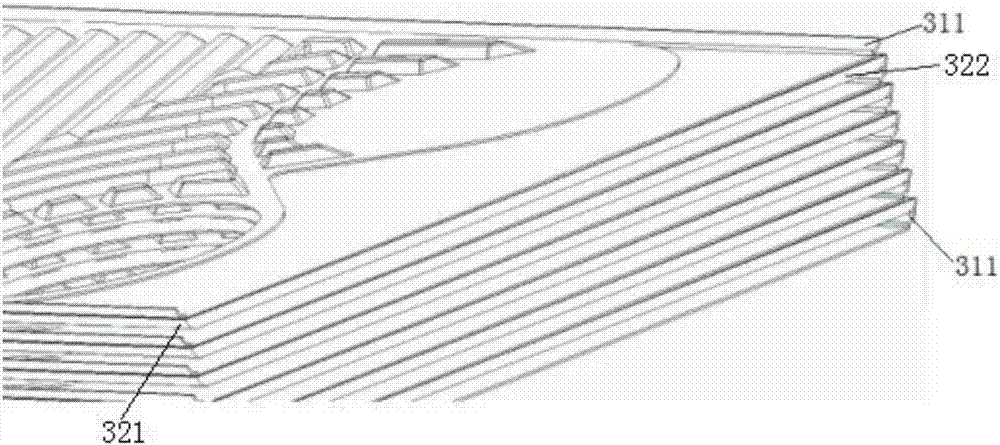

[0025] figure 1 is a three-dimensional schematic view of the EGR cooler of the present invention, figure 2 It is an expanded perspective view of the EGR cooler of the present invention.

[0026] Such as figure 1 , figure 2 As shown, the EGR cooler 100 provided by the present invention includes a cover plate 1 , a bottom plate 2 and a core body 3 .

[0027] The cover plate 1 has a horizontal part 11 and a vertical part 12 arranged at both ends of the horizontal part, a water outlet 13 is arranged on one side of one end of the horizontal part 11, and a waste gas inlet is arranged on the vertical part 12 close to the water outlet 13 14. The other vertical part 12 is provided with a waste gas outlet 15.

[0028] The bottom plate 2 is connected to the two vertical parts 12 through connecting parts 21 respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com