Absorption article and manufacturing method thereof

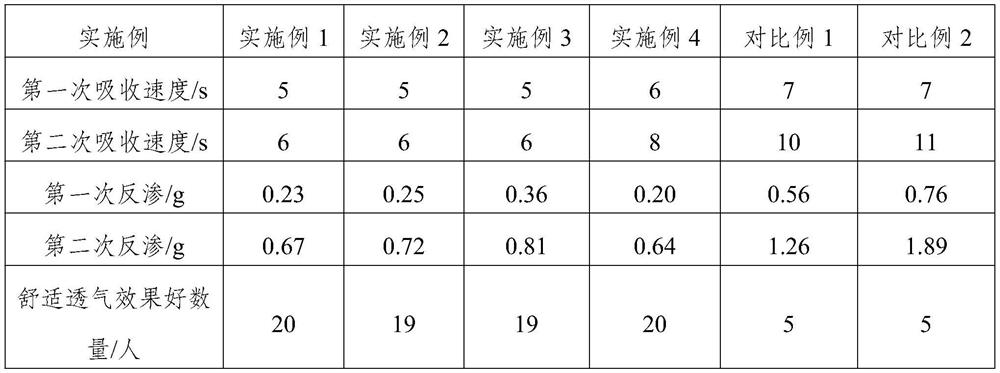

An absorbent article and absorbent layer technology, which is applied in the field of sanitary and hygienic articles, can solve the problems of easy breeding of bacteria, slow infiltration speed, uncomfortable wearing, etc., and achieve the effects of improving dryness, fast infiltration speed and comfortable wearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

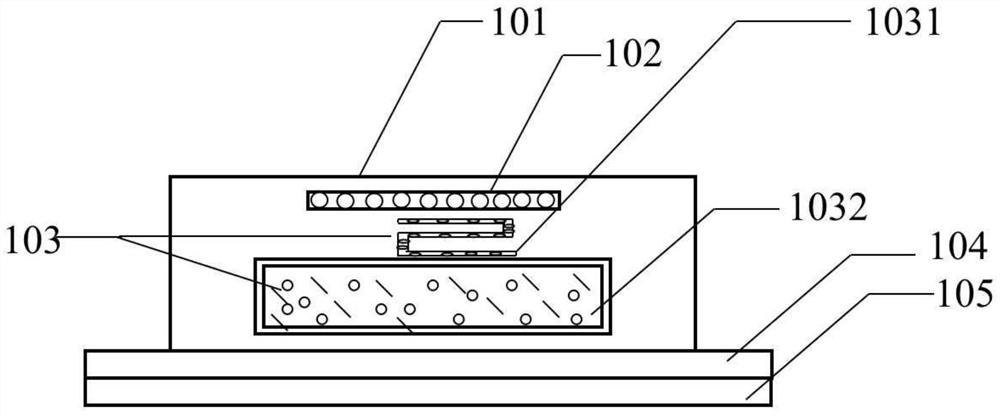

[0085] (1) Make superabsorbent resin water-absorbing paper (gram weight is 150g / m 2 ) is folded into three folded raised cores by folding equipment to obtain the first absorbent layer 1031;

[0086] (2) After the fluff pulp is crushed and super absorbent resin (particle size 30-100 mesh, water retention capacity not less than 25g / g, liquid flow capacity not less than 0.1mL / min) in the hub at a mass ratio of 5:3 Mixing, setting through a shaping cover, and wrapping with a spun-bonded non-woven fabric to obtain the second absorbent layer 1032;

[0087] (3) composite the first absorbent layer 1031 and the second absorbent layer 1032 to obtain the absorbent layer 103;

[0088] (4) On the upper layer of the absorbent layer 103, the flow guide layer 102 (wet-processed superabsorbent resin absorbent paper) and the liquid-permeable surface layer 101 (silk non-woven fabric, the fiber denier is 0.5 denier) are sequentially combined, and the absorbent layer 103 The lower layer of the l...

Embodiment 2

[0092] (1) Make superabsorbent resin water-absorbing paper (gram weight is 100g / m 2 ) is folded into three folded raised cores by folding equipment to obtain the first absorbent layer 1031;

[0093] (2) After the fluff pulp is crushed and super absorbent resin (particle size 30-100 mesh, water retention capacity not less than 25g / g, liquid flow capacity not less than 0.1mL / min) in the hub at a mass ratio of 2:1 Mixing, setting through a shaping cover, and wrapping with a spun-bonded non-woven fabric to obtain the second absorbent layer 1032;

[0094] (3) Composite the first absorbing layer 1031 and the second absorbing layer 1032 to obtain the absorbing layer 103 .

[0095] (4) Composite diversion layer 102 (superabsorbent resin water-absorbent paper made by wet method, grammage is 150g / m) on the upper layer of absorption layer 103 2 ) and the liquid-permeable surface layer 101 (hot air non-woven fabric), and the lower layer of the absorbent layer 103 is sequentially composi...

Embodiment 3

[0099] (1) Make superabsorbent resin water-absorbent paper (gram weight is 70g / m 2 ) is folded into three folded raised cores by folding equipment to obtain the first absorbent layer 1031;

[0100] (2) After crushing the fluff pulp and superabsorbent resin (particle size 30-100 mesh, water retention capacity not less than 25g / g, liquid flow capacity not less than 0.1mL / min) in the hub at a mass ratio of 10:1.5 Mixing, setting through a shaping cover, and wrapping with a spun-bonded non-woven fabric to obtain the second absorbent layer 1032;

[0101] (3) Composite the first absorbing layer 1031 and the second absorbing layer 1032 to obtain the absorbing layer 103 .

[0102] (4) Composite diversion layer 102 (superabsorbent resin water-absorbing paper made by wet method, grammage is 100g / m) on the upper layer of the absorbing layer 2 ) and liquid-permeable surface layer 101 (silk non-woven fabric, fiber denier is 2 deniers), and the lower layer of the absorbent layer 103 is se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com