Attached mounting type miniature compound dynamic vibration absorber

A dynamic vibration absorber and duplex technology, applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problems of high stiffness of compression structure rubber, reduced use function and life, and easy falling off of mass blocks. Achieve reasonable distribution of resonance frequency, enhance vibration and noise reduction performance, and facilitate disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

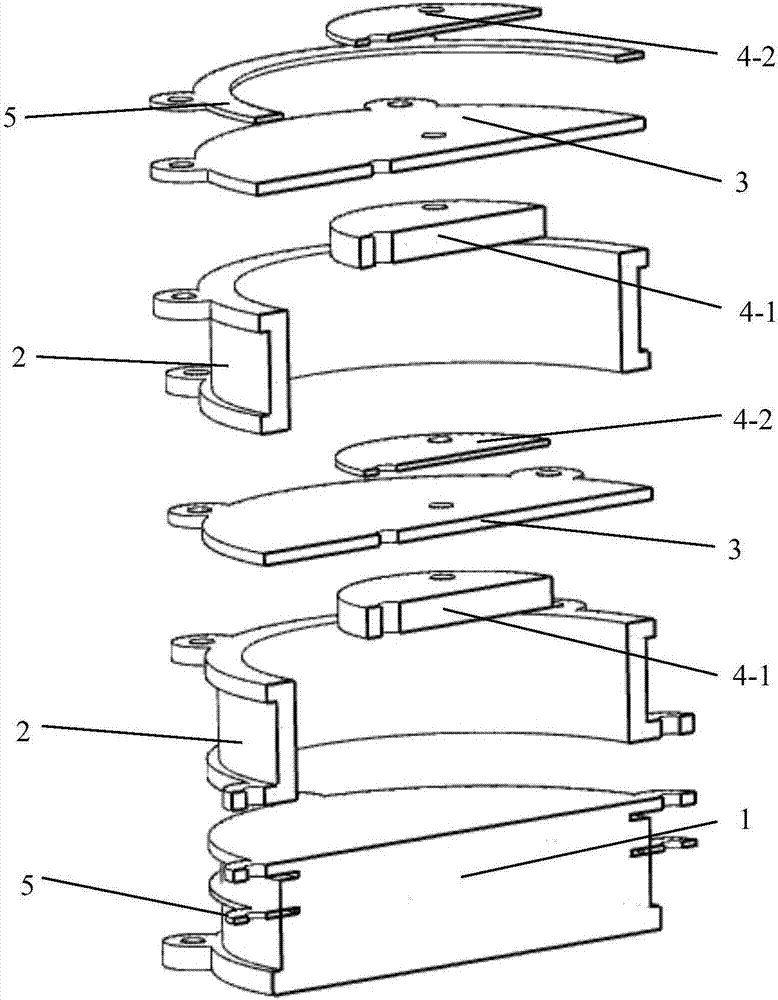

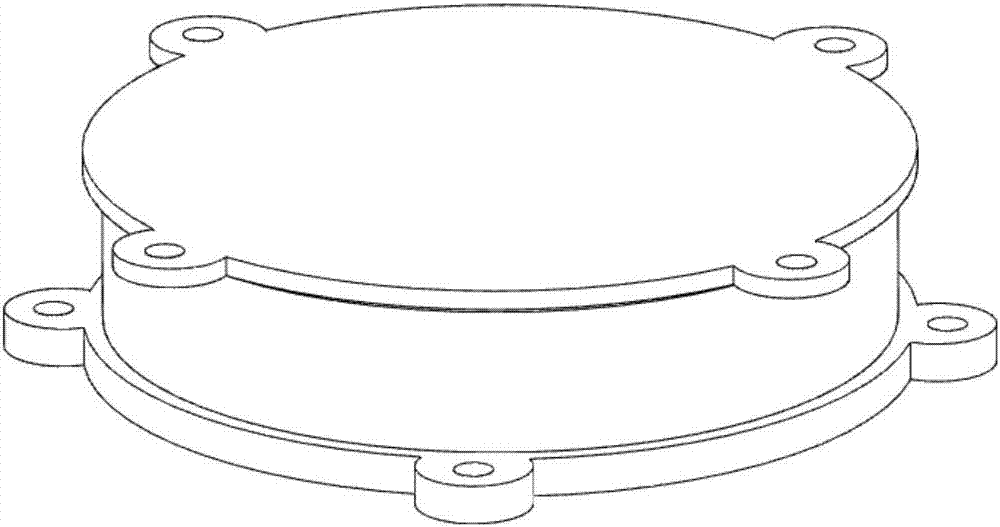

[0025] Such as figure 1 Shown is the attached miniature compound dynamic shock absorber of the present invention, figure 2 Shown is an exploded cross-sectional view of the attached miniature compound dynamic vibration absorber, including: elastic base 1, assembly bracket 2, elastic membrane 3, quality block 4, connector 5 for assembly of the compound dynamic vibration absorber, elastic base 1 The main body of the compound dynamic shock absorber is composed of two assembly brackets 2, and the elastic base 1 is a rubber-like column structure, such as image 3 shown. There are two assembly supports 2, all of which are metal tubular structures with a certain height, such as Figure 4 As shown, one assembly bracket and elastic base 1, connector 5 (such as Figure 5 shown) connection. Install vibration-absorbing components inside the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com