Buried pipe optimization method and system based on seasonal energy storage

An optimization method and technology for buried pipes, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as increased drilling costs, small soil thermal conductivity, and large distance between buried pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

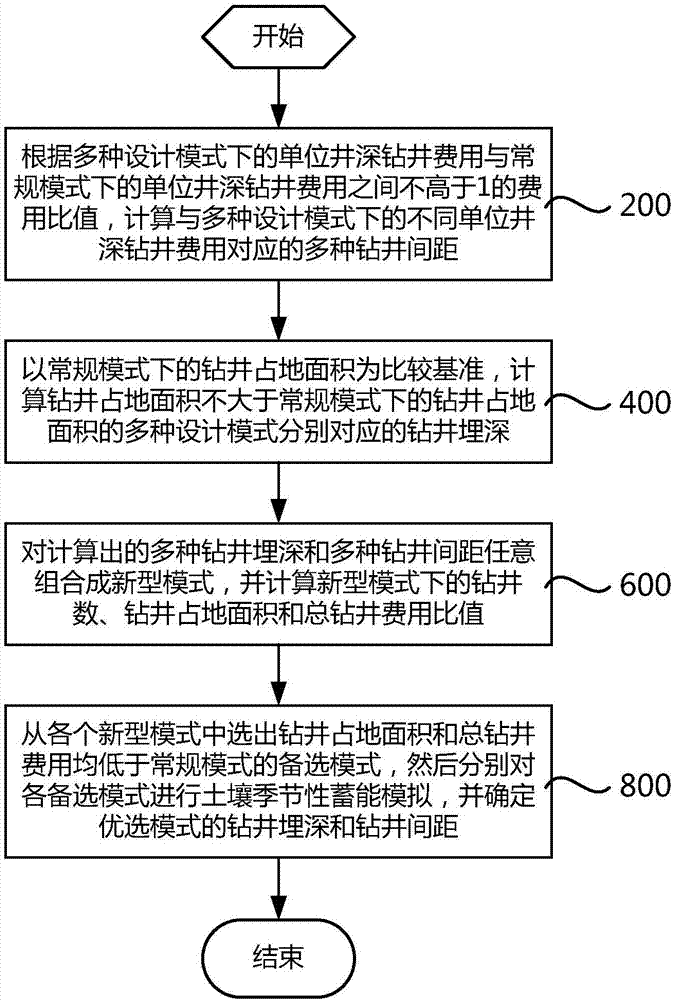

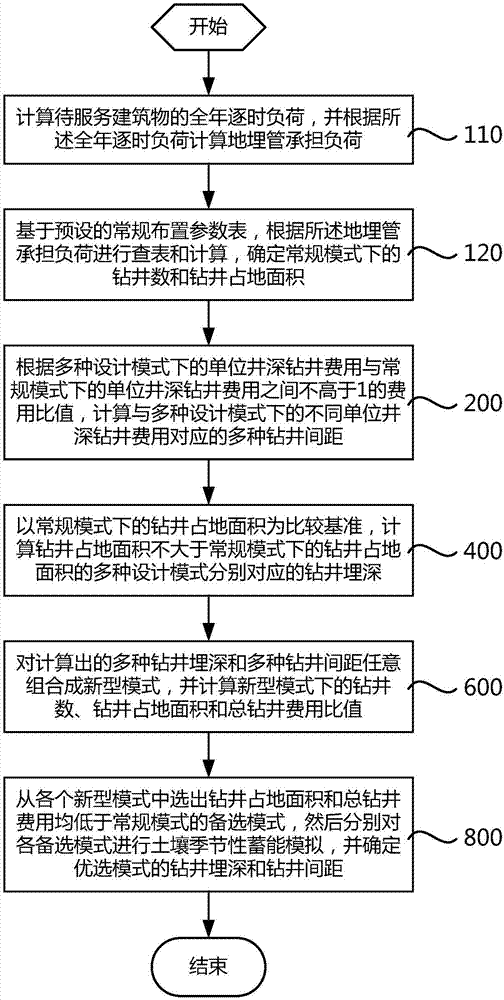

[0090] like figure 1 As shown, it is a schematic flowchart of an embodiment of the method for optimizing buried pipes based on seasonal energy storage in the present invention. In this embodiment, the buried pipe optimization method based on seasonal energy storage includes:

[0091] Step 200, according to the cost ratio between the drilling cost per well depth in various design modes and the drilling cost per well depth in the conventional mode, which is not higher than 1, calculate the corresponding multi-drilling costs for different unit depths in various design modes Drilling spacing;

[0092] Step 400, taking the drilling footprint in the conventional mode as a comparison reference, calculating the drilling depths corresponding to the various design modes whose drilling footprint is not larger than the drilling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com