Gas-solid combined type heat-carrying oil shale fluidized bed dry distilling system

A fluidized bed and combined technology, which is applied in the field of gas-solid combined heat transfer oil shale fluidized bed retort system, can solve the problems of poor resistance to market economic impact, serious environmental pollution, and low resource utilization. Achieve the effects of avoiding gas leakage and air mixing, prolonging the dry distillation time and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

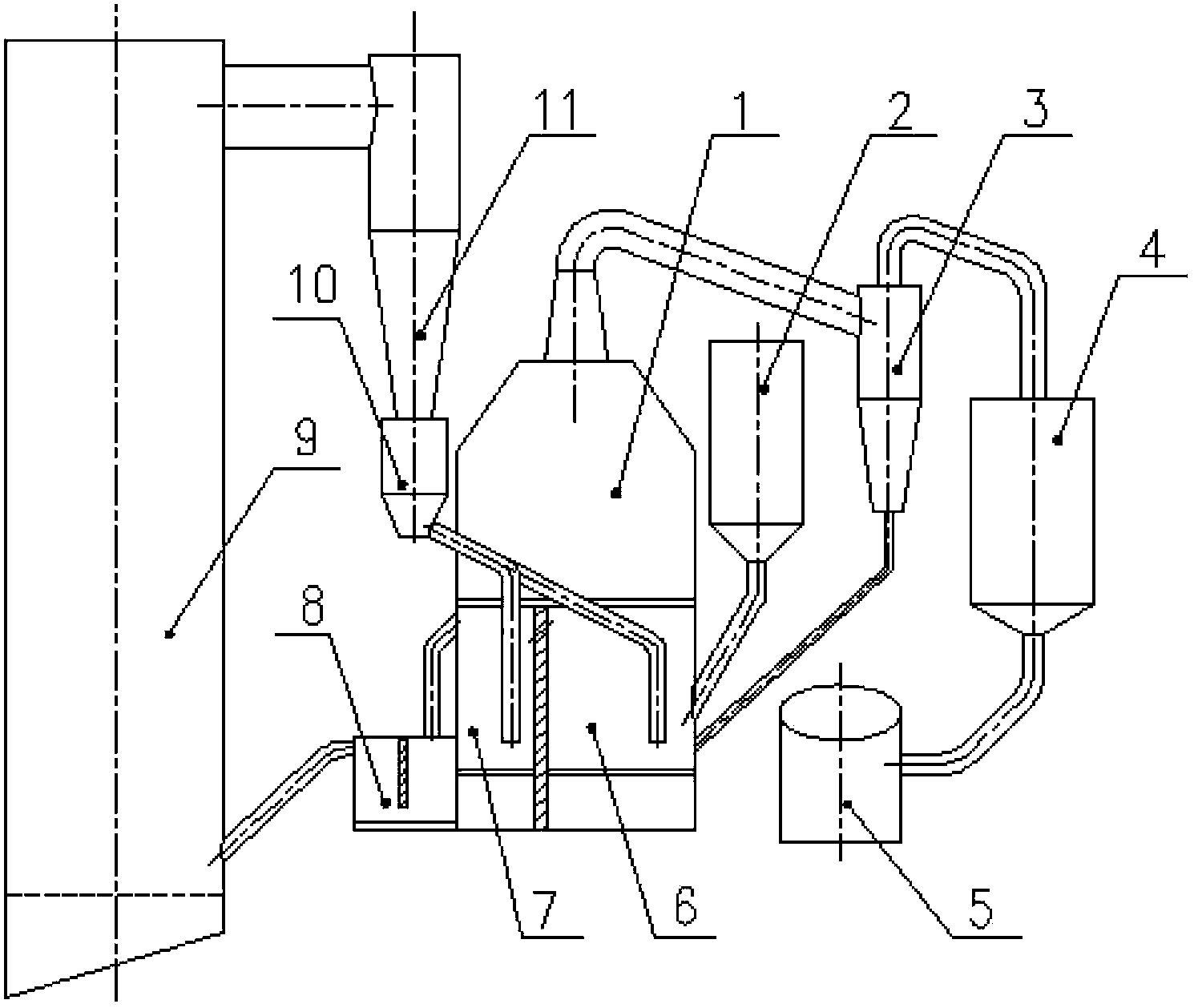

[0021] Gas-solid combined heat-carrying oil shale fluidized bed dry distillation system, its structure is as figure 1 As shown, the system includes a fluidized bed dry distillation furnace 1, an oil shale warehouse 2, a gas-solid separator 3, a gas-liquid separator 4, an oil-water separator 5, a low temperature fluidized bed dry distillation chamber 6, a high temperature fluidized bed dry distillation chamber 7. Return valve 8, semi-coke circulating fluidized bed 9, shale ash bin 10, shale ash separator 11. The above components are connected in the following ways: the lower outlet of the oil shale bin 2 is connected with the low temperature fluidized bed dry distillation chamber at the bottom of the fluidized bed dry distillation furnace 1 6 the oil shale inlet, and the upper overflow port of the low temperature fluidized bed dry distillation chamber 6 is connected with high temperature fluidization The bed dry distillation chamber 7 is connected with the semi-coke inlet, the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com