Coal combustion CO2 capturing method and device based on metal oxide-CaCO3 absorbent

An oxide, CO2 technology, applied in chemical instruments and methods, carbon compounds, separation methods, etc., can solve the problems of reduced absorption capacity, low volume share, reduced CaO conversion degree, etc., to achieve low price, avoid absorption capacity, achieve The effect of system energy balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

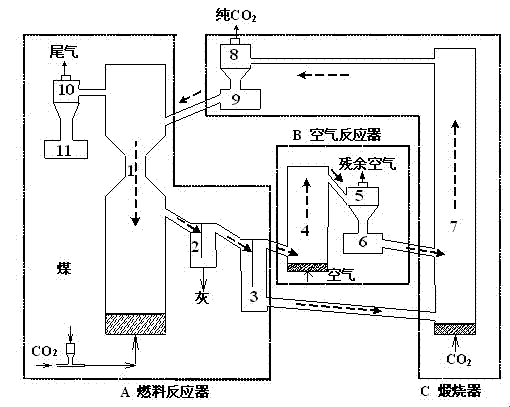

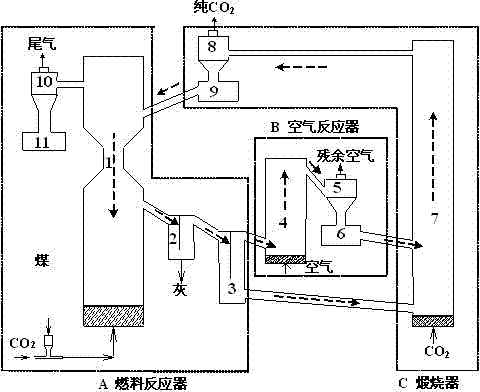

[0040] The pulverized coal combustion CO proposed by the present invention 2 capture devices such as figure 1 As shown, the two-stage bubbling fluidized bed 1, coal ash separator 2, CaCO 3 The separator 3, the third cyclone separator 10 and the coal fly ash trap 11 form the fuel reactor system A; the fast fluidized bed 4, the first cyclone separator 5 and the first sealing valve 6 form the air reactor system B; Finally, the calciner system C is composed of the fast fluidized bed 7, the second cyclone separator 8, and the second sealing valve 9 connected in sequence.

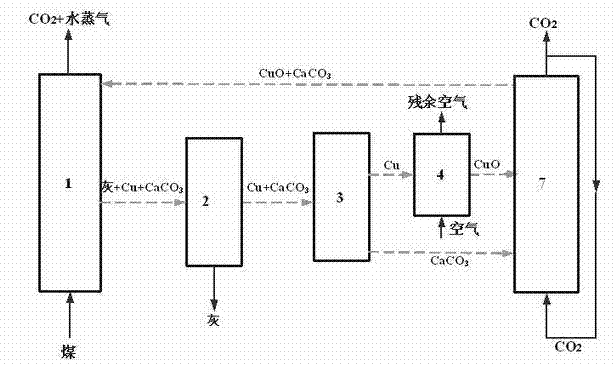

[0041] The present invention uses carbon-containing fuels such as coal and CuO-limestone composite carrier as raw materials to carry out a series of reactions to complete the full combustion of coal and high-concentration CO 2 The capture process is as follows figure 2 As shown, the specific implementation is as follows:

[0042] 1. First, in the lower half of the fuel reactor 1, the reaction temperature is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com