Electric vehicle charging pile cooling cable

A technology for electric vehicles and charging piles, applied in the field of power cables, can solve problems such as limited heat dissipation and cooling effects, small heat transfer area, damage to cables and charging equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

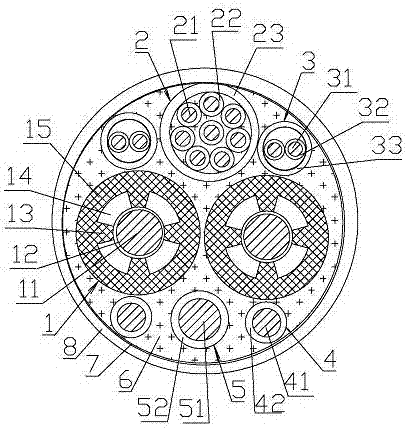

[0019] Such as figure 1 As shown in the electric vehicle charging pile cooling cable, the cable core of the cooling cable consists of two power cables 1, one ground wire 5, two auxiliary power cables 4, two signal cables 3 and one control cable 2 composition. The cable core is filled with a filler 6, which is a highly flame-resistant PP mesh filler rope, and of course it can also be a hydrophobic filler or other commonly used cable core filler materials; the above structure makes the power cable 1, ground The wires 5, auxiliary power cables 4, signal cables 3 and control cables 2 are all buried in the filler 6 and surrounded by the filler material. A tape layer 7 is covered outside the cable core, and a cable outer sheath 8 is extruded on the tape layer 7 . In this implementation, the tape layer 7 is a non-woven tape layer, and the cable outer sheath 8 is extruded from a low-smoke halogen-free cable sheath material.

[0020] The power cable 1 includes a power cable conducto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com