Electrostatic eliminator based on conductive composite nano-materials

A technology of composite nanomaterials and static eliminator, which is applied in the direction of static electricity and electrical components, can solve problems such as the inability to effectively eliminate static electricity hazards, and achieve the effects of increasing heat insulation performance, improving toughness and improving electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

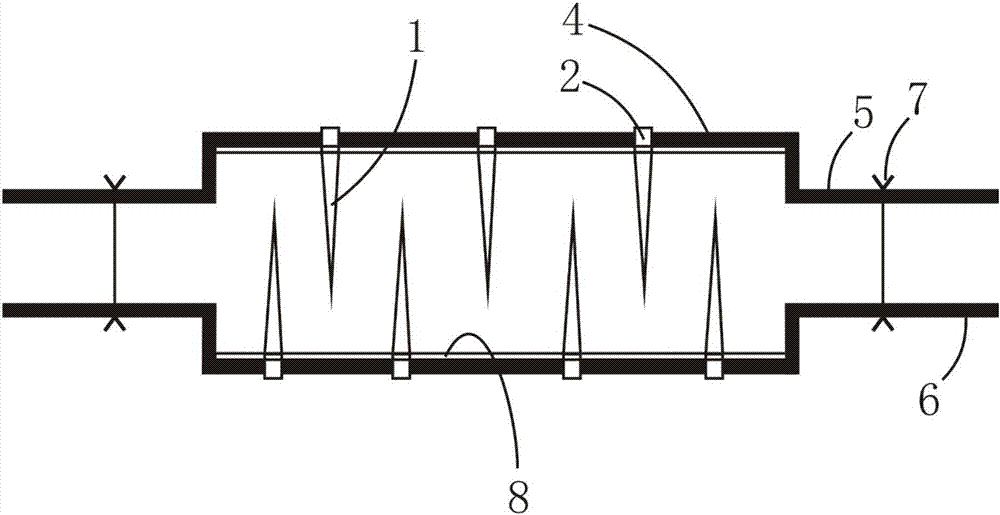

Image

Examples

Embodiment

[0022] Embodiment: In the embodiment of the present application, the preparation process of the conductive composite nanomaterial is:

[0023] S1, first treating a certain amount of carbon nanotubes in ultrasonic waves for 2 hours to activate their surfaces, then mixing them with calcium carbonate in proportion, and then ultrasonically treating them for 1 hour to obtain a mixture of carbon nanotubes and calcium carbonate;

[0024] S2, the above mixture and PA12 were dried in a vacuum oven for 20 hours, and the melt blending method was used to first blend the mixture of PA12, carbon nanotubes and calcium carbonate at 260 ° C for 15 minutes using a micro extruder, and then The resulting PA12 / carbon nanotube / calcium carbonate nanocomposite material was blended with POE-g-MA for 5 minutes, wherein the screw speed was 50rpm, and then the conductive composite nanomaterial described in this application was obtained, and then the conductive composite nanomaterial of suitable size was m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com