Sterilization method of natural casing for sausages

A casing and natural technology, applied in sausage casings, cleaning intestines, slaughtering, etc., can solve the problems of strength, process cannot be copied, etc., achieve the effect of short sterilization treatment time, less environmental pollution and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

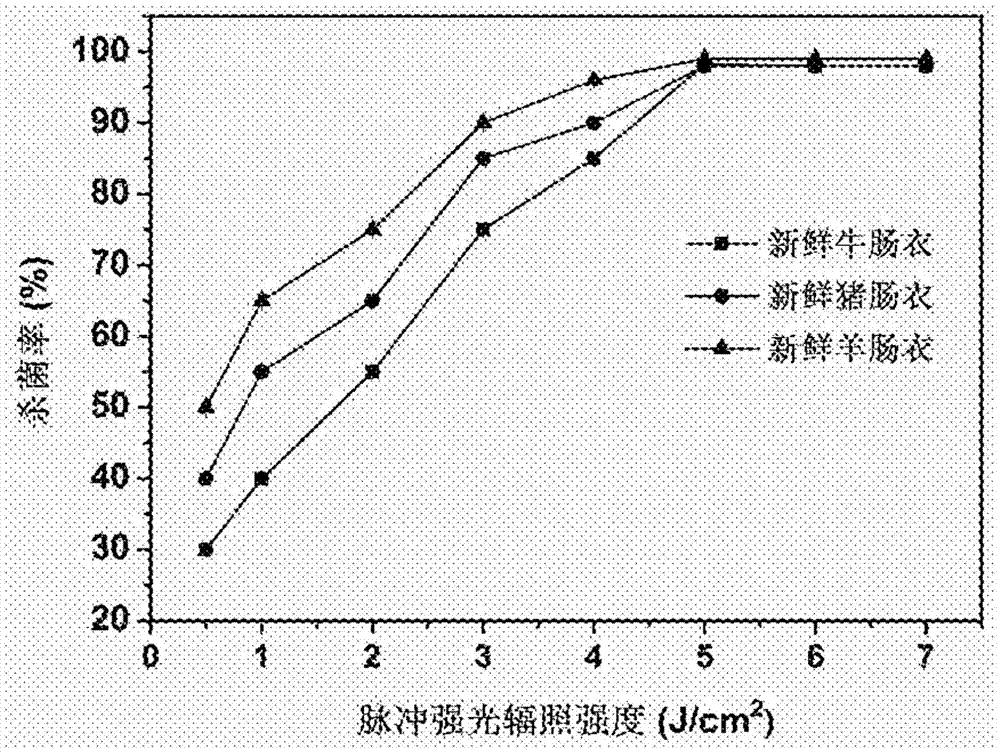

Embodiment 1

[0031] (1) Original intestine selection: choose fresh beef casings that have not been salted, and the casings are free of debris and odor;

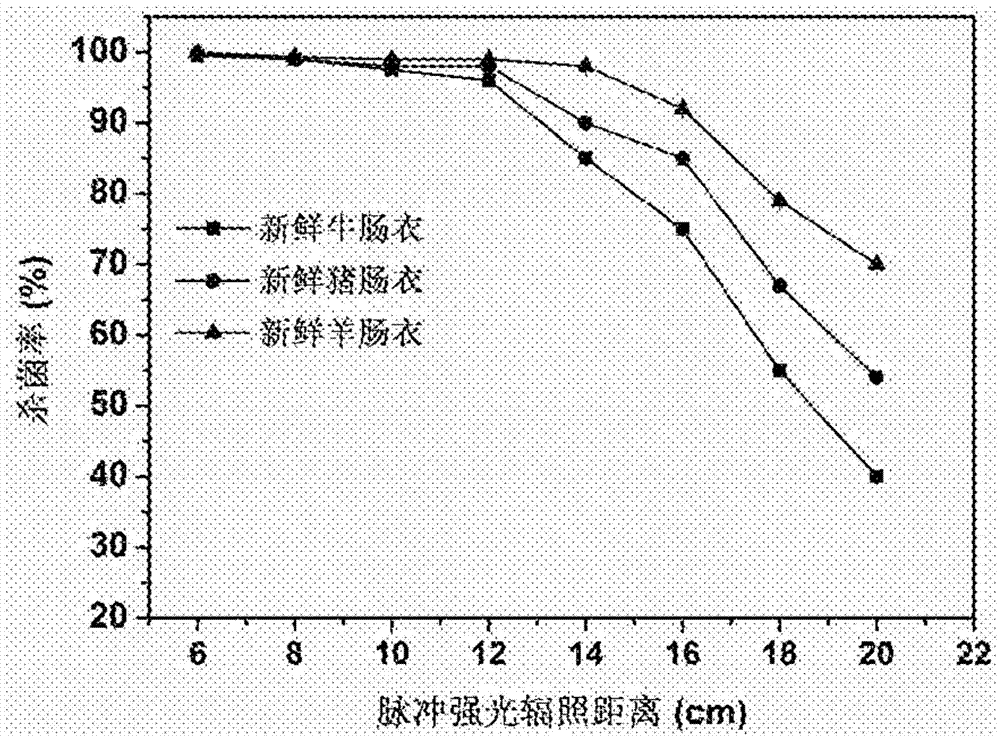

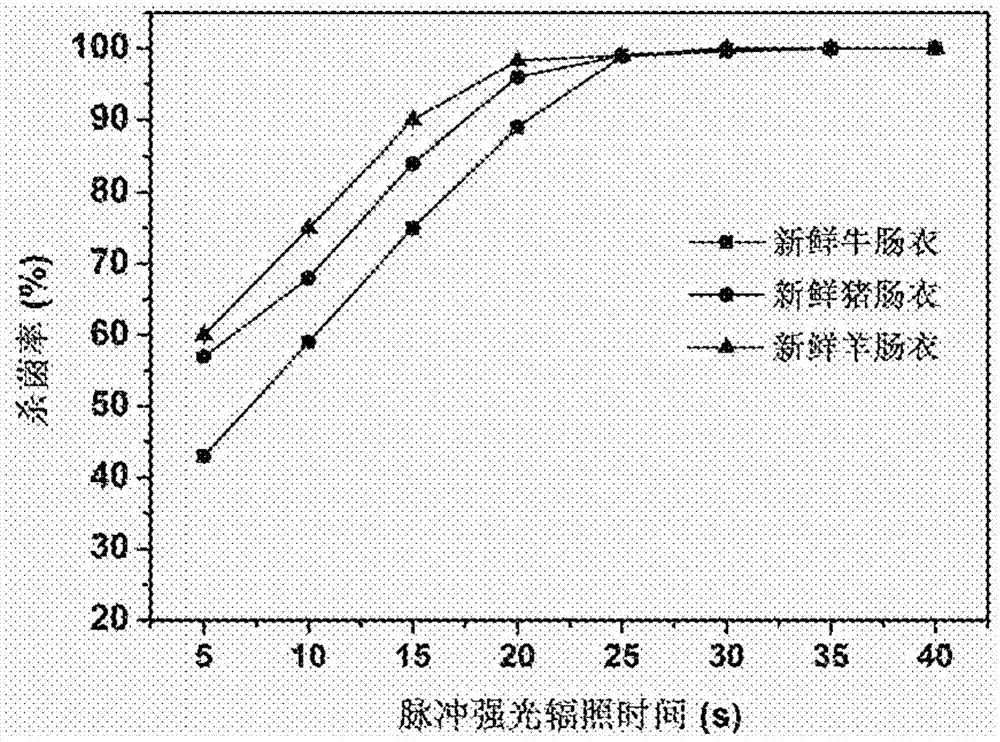

[0032] (2) One-time pulse strong light sterilization: transport the casings to the pulse strong light sterilization equipment, the pulse strong light sterilization intensity is 6J / cm2, the flashing distance is 8cm, the flashing time is 25s on the front and back sides, 7 flashes per second times, and ensure that the casings are not overlapped during the sterilization process;

[0033] (3) Vacuum packaging: lay the casings flat without overlapping and put them into the packaging bags for vacuum packaging;

[0034] (4) Secondary pulse strong light sterilization: transport the casings to the pulse strong light sterilization equipment, the pulse strong light sterilization intensity is 3J / cm2, the flashing distance is 20cm, the flashing time is 10s on the front and back sides, flashing every second 3 times, and ensure that the packaging is not...

Embodiment 2

[0037] (1) Original intestine selection: choose fresh pig casings that have not been salted, and the pig casings have no sundries and no peculiar smell;

[0038] (2) One pulse strong light sterilization: transport casings to the pulse strong light sterilization equipment, the pulse strong light sterilization intensity is 5J / cm2, the flashing distance is 10cm, the flashing time is 24s on the front and back sides, 5 flashes per second times, and ensure that the casings are not overlapped during the sterilization process;

[0039] (3) Vacuum packaging: lay the casings flat without overlapping and put them into the packaging bags for vacuum packaging;

[0040] (4) Secondary pulse strong light sterilization: transport the casings to the pulse strong light sterilization equipment, the pulse strong light sterilization intensity is 2J / cm2, the flashing distance is 23cm, the flashing time is 8s on the front and back sides, flashing every second 3 times, and ensure that the packaging til...

Embodiment 3

[0043] (1) Original intestine selection: choose fresh sheep casings that have not been salted, and the sheep casings have no sundries and no peculiar smell;

[0044] (2) One-time pulse strong light sterilization: transport the casings to the pulse strong light sterilization equipment, the pulse strong light sterilization intensity is 4J / cm2, the flash distance is 15cm, the flash time is 20s on the front and back sides, and 5 flashes per second. times, and ensure that the casings are not overlapped during the sterilization process;

[0045] (3) Vacuum packaging: lay the casings flat without overlapping and put them into the packaging bags for vacuum packaging;

[0046] (4) Secondary pulse strong light sterilization: transport the casings to the pulse strong light sterilization equipment, the pulse strong light sterilization intensity is 1J / cm2, the flashing distance is 27cm, the flashing time is 6s on the front and back sides, flashing every second 2 times, and ensure that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com