Robot closed-loop machining system used for pin welding of membrane water wall

A membrane-type water-cooled wall and welding robot technology, applied in general control systems, welding equipment, auxiliary welding equipment, etc., can solve problems such as deviations in theoretical model parameters, improve welding quality, save labor and time, and achieve good economic benefits and the effect of social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

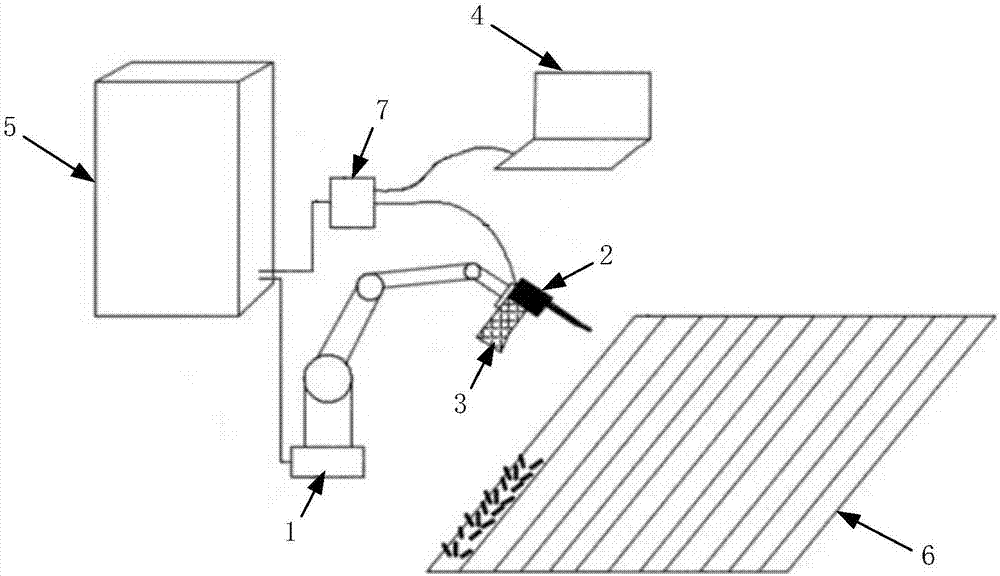

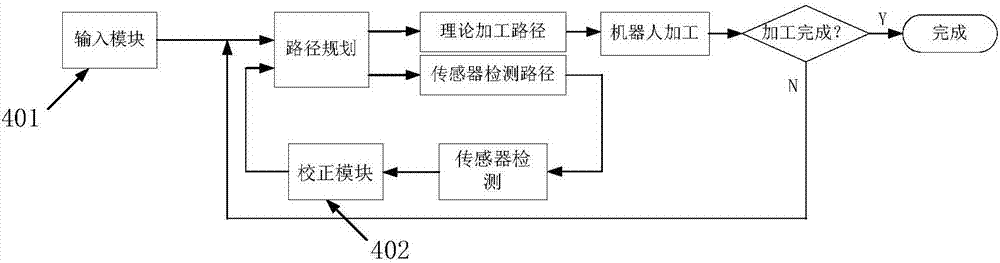

[0024] The present invention is used for the robot closed-loop processing system of membrane type water-cooled wall pin welding, comprises welding robot 1, welding torch head 2, sensor 3, upper computer 4, controller 5 and communication equipment, such as figure 1 shown.

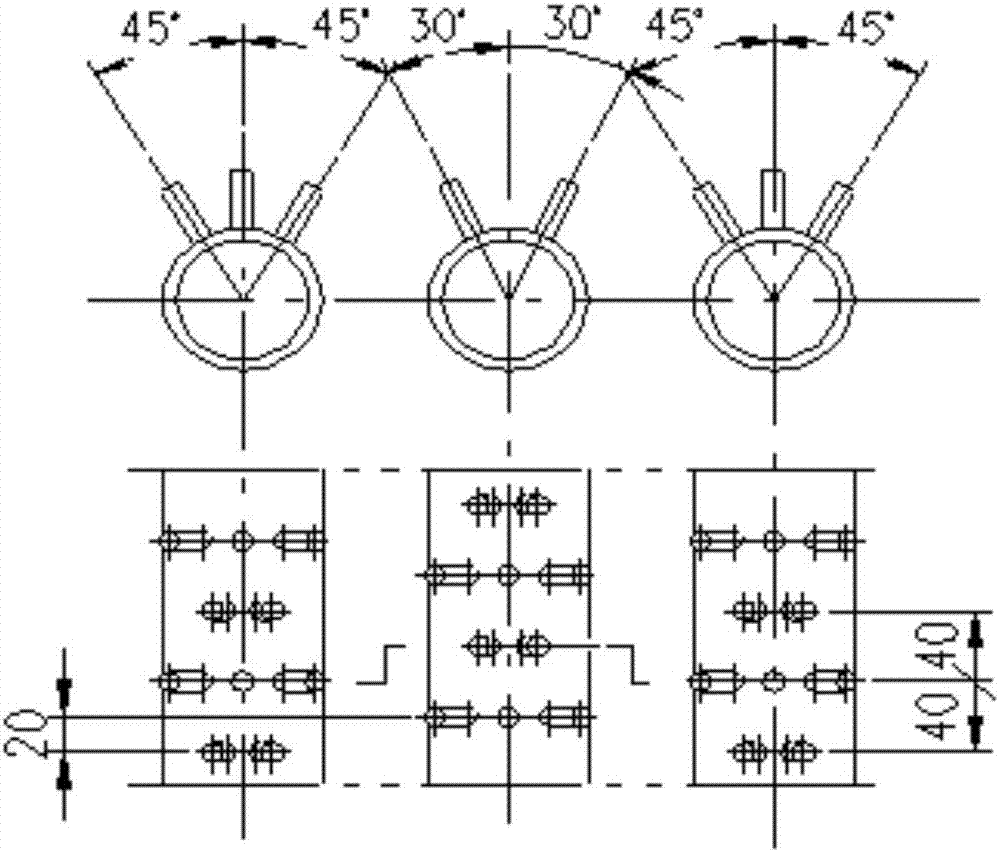

[0025] The welding robot 1 is a welding arm with a welding torch head 2 installed at its end, which is used to guide the welding torch head 2 to perform spot welding in the direction of the normal vector of the welding spot on the steel pipe of the membrane water wall 6 . The sensor 3 is a laser cross-section sensor, which is fixed to the end of the welding robot 1 by bolts, so that the sensor 3 can follow the movement of the welding torch head 2, and the sensor scans the contour of the membrane water cooling wall 6 . The membrane water-cooled wall 6 is a continuous side-by-side welded surface of flat st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com