Steel belt reinforced PE helical bellow welding device and application method thereof

A spiral corrugated pipe and welding device technology, which is applied in the field of steel belt reinforced PE spiral corrugated pipe welding device, can solve the problems of inaccessible workers, high leakage rate, poor sealing effect, etc., to reduce labor intensity and high operating efficiency , the effect of solving welding problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

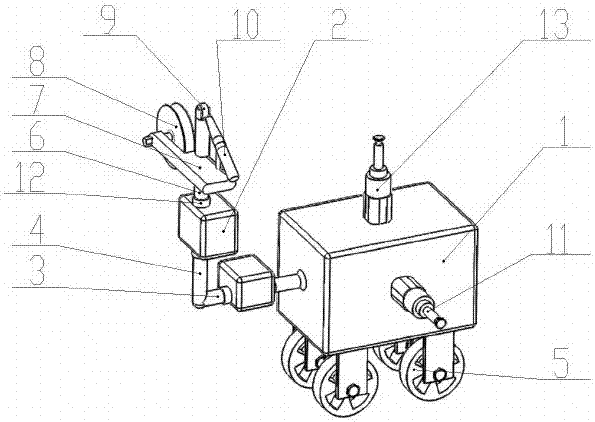

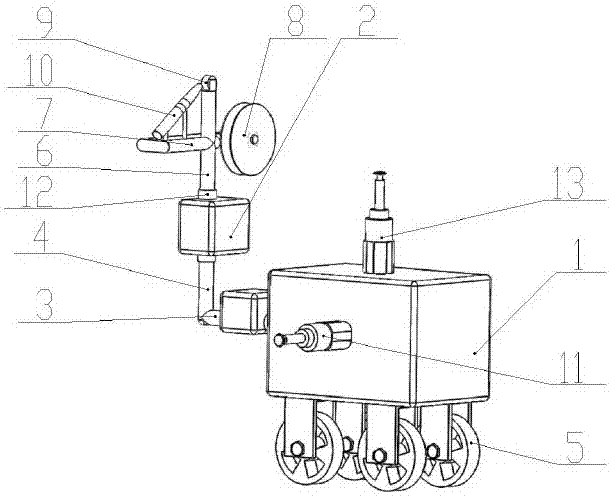

[0024] Embodiment one: as attached figure 1 , 2 As shown, the steel strip reinforced PE spiral corrugated pipe welding device includes a box body 1, a first stepping motor, a second stepping motor 2, a horizontal telescopic support arm 3, a vertical telescopic support arm 4 and a welding torch assembly, The bottom of the box body 1 is fixedly installed with a walking wheel 5, and on the outer wall of the box body 1 is fixedly installed at least one telescopic strut that can be tightened on the inner wall of the steel belt reinforced PE spiral corrugated pipe, and inside the box body 1 is fixedly installed with a first Stepping motor, the first power output shaft left end of the first stepping motor is fixedly installed with the horizontal telescopic support arm 3 extending out of the left side wall of the box body 1, the second power output shaft of the first stepping motor and the walking wheel The rotating shaft of 5 is connected, the left end of the horizontal telescopic s...

Embodiment 2

[0031] Embodiment two: the following is the using method of above-mentioned embodiment one: comprise the following steps:

[0032] In the first step, the heat shrinkable tape is wound on the heat shrinkable tape reel 8, and the exposed end of the heat shrinkable tape is glued to the pressing roller 9;

[0033] The second step is to start the second power output shaft of the first stepping motor, so that the traveling wheel 5 drives the steel belt reinforced PE spiral corrugated pipe welding device to enter the joint of the two steel belt reinforced PE spiral corrugated pipes, and starts the telescopic strut, so that It is pressed against the inner side of the steel belt reinforced PE spiral bellows, and then by adjusting the length of the vertical telescopic support arm 4, the pressing roller 9 is aligned with the annular joint of the axial joint of the corresponding two steel belt reinforced PE spiral bellows. Seam starting position, and start the heat gun 10;

[0034] The t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com