Deinking unit and waste paper recycling unit

A processing device and deinking technology, which is applied in the processing of waste paper, textiles and papermaking, fiber raw material processing, etc., can solve the problem of difficulty in realizing the miniaturization of the device, and achieve the effect of simplifying the device structure and realizing the device structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

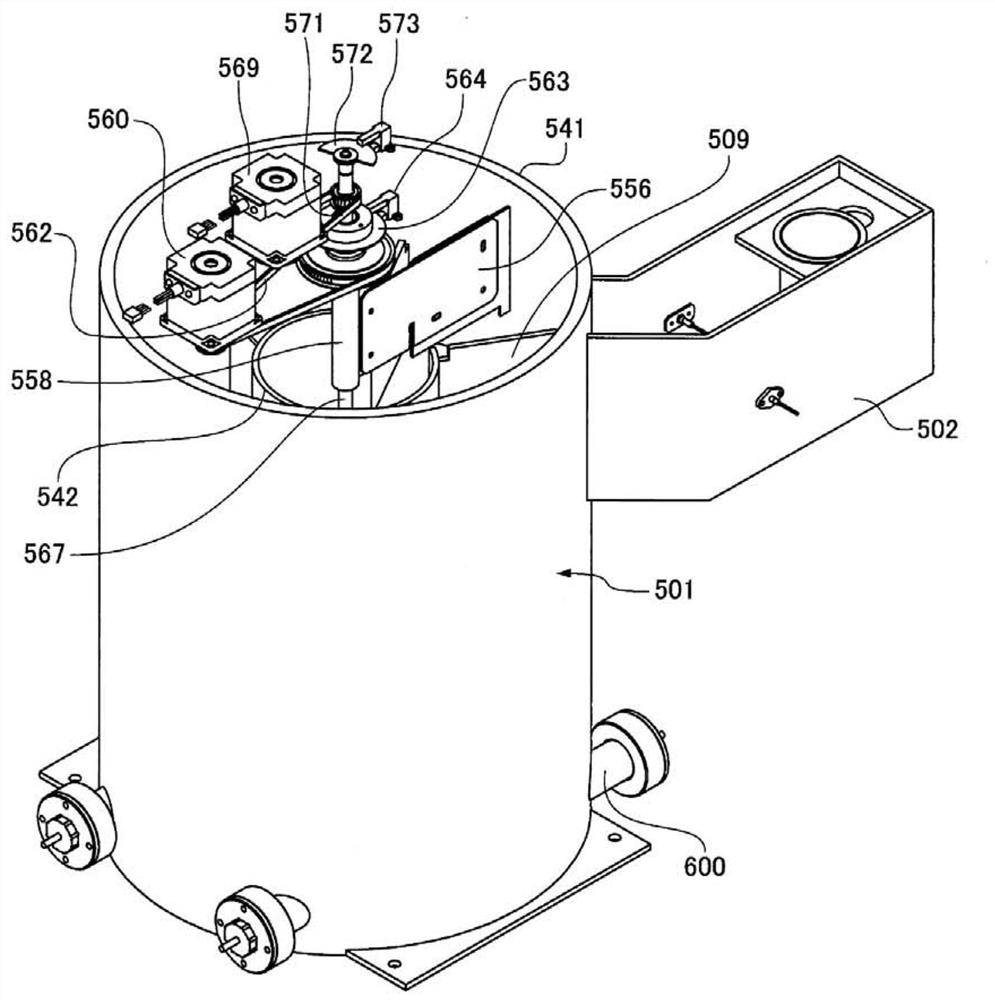

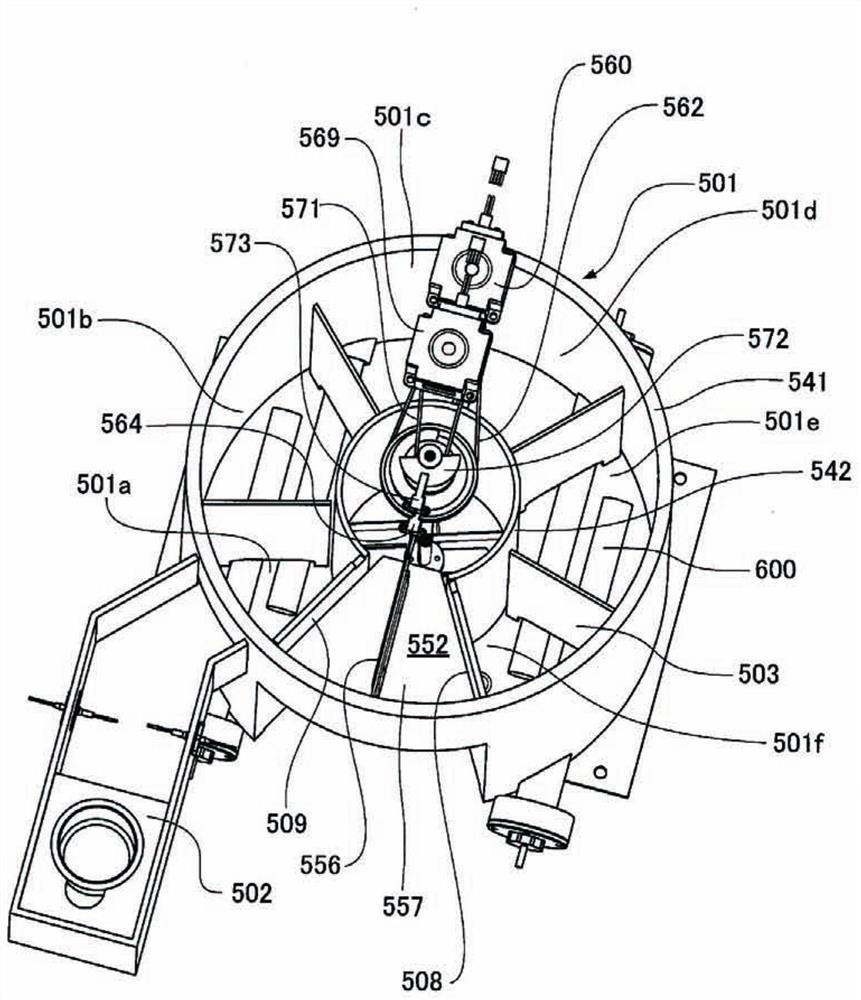

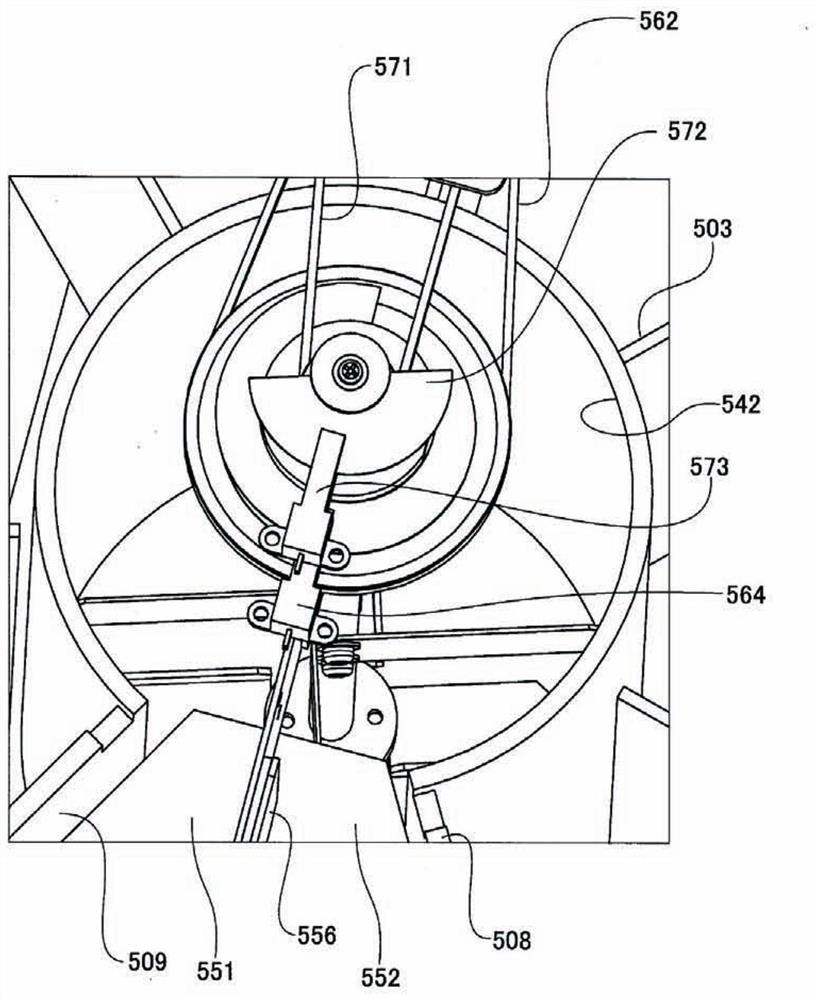

[0030] Embodiments of the present invention will be described below with reference to the drawings. Such as Figure 13 As shown, the waste paper recycling apparatus has a plurality of processing units constituting a waste paper recycling system. The processing section includes a waste paper input section 1 , a pulping section 9 , a deinking section 11 , a papermaking section 13 , a drying section 14 , a finishing section 15 and a white water container section 100 . Moreover, the waste paper recycling processing apparatus is provided with the control part 700 for controlling the operation|movement of each processing part.

[0031] The used paper input unit 1 is used to input used paper used as a recycled raw material into the pulping unit 9 , and input the used paper into the pulping unit 9 in a state of holding sheets or in a state of cutting. The pulping unit 9 has a tank body 91 and a stirring device 92 installed in the tank body 91 , and decomposes waste paper to produce ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com