Well killing operation throttle valve automatic control system based on feedback adjustment and method thereof

An automatic control system and feedback adjustment technology, which is applied in earthwork drilling, wellbore flushing, wellbore/well components, etc., can solve the problem of pressure transmission lag, difficulty in manually adjusting standpipe pressure, and easy occurrence of lost circulation or blowout, etc. problems, to avoid out-of-control operations, reduce the possibility of errors, and reduce the complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

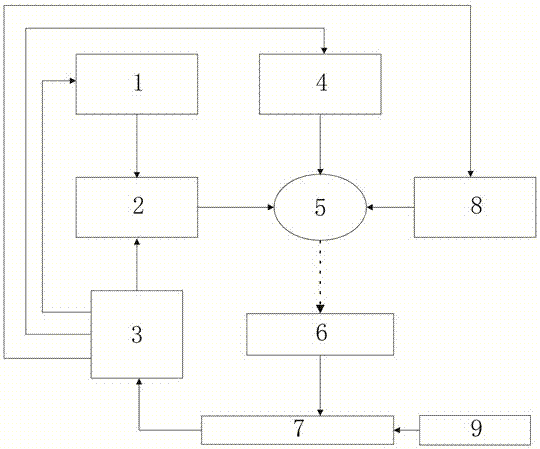

[0020] Such as figure 1 As shown in the figure, an automatic control system for the choke valve in well killing operation based on feedback adjustment, which includes a self-healing controller (1), a PLC controller (2), a central computer (3), a feedback compensator (4), a throttle Flow valve (5), riser pressure transmitter (6), sensor-data acquisition system (7), feed-forward compensator (8), basic data source (9).

[0021] Use the sensor-data acquisition system (7) to collect the necessary data for well killing operations including drilling fluid circulation increment, riser pressure, casing pressure, etc., which can also be used as a reference for manual operations when necessary; the central computer (3) collects data for calculation and multiphase flow numerical simulation, the standpipe pressure control curve and the initial control curve of the throttle valve (5) ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com