Vacuum extruding machine of novel series

A vacuum extruder and series technology, applied in the field of new series of vacuum extruders, can solve the problems of increasing design and manufacturing costs, increasing application maintenance costs, etc., to reduce manufacturing difficulty and shape parameters, effectively control mechanical friction temperature, product The effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

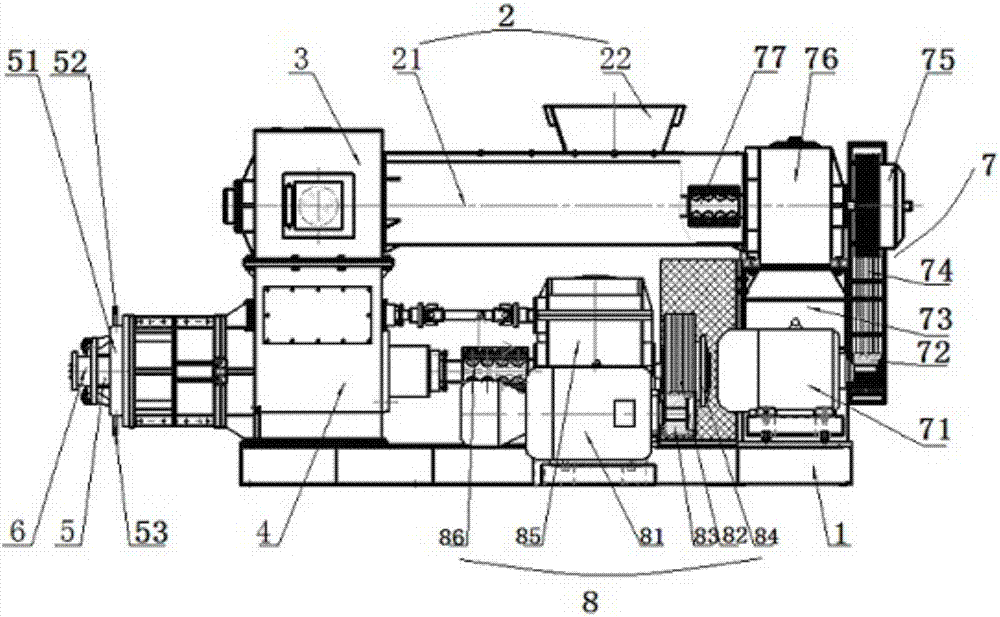

[0028] With reference to the overall structure of the present invention figure 1 , including a stirring system 2, the stirring system 2 includes a stirring box 21, and the top of the stirring box 21 has a feed hopper 22; the mud material enters the stirring box 21 from the feed hopper 22 to be stirred more compactly, and the vacuum System 3 is set at one end of the mixing system 1, and the vacuum system 3 is connected through the mixing system 1; the vacuum system 3 forms a vacuum that meets the required vacuum degree under the action of the vacuum pump, which helps to improve the compactness of the raw materials. The vacuum extrusion system 4 is arranged below the vacuum system 3, and the vacuum extrusion system 4 further squeezes the mud falling from the vacuum system 3 more compactly. The lower port of the vacuum system 3 and the upper por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com