Powder return device for hard capsules

A hard capsule and powder returning technology, which is applied in the field of hard capsule powder returning device, can solve the problems of cross contamination, manpower and time consumption, waste, etc., and achieve the effect of high powder returning efficiency, fast cutting speed and pure drug powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

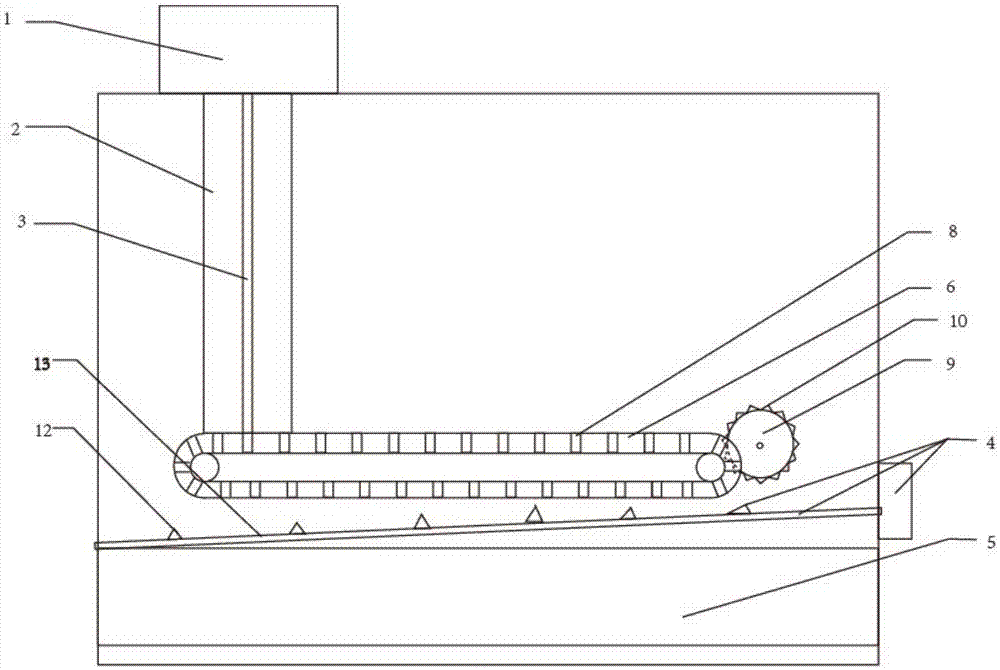

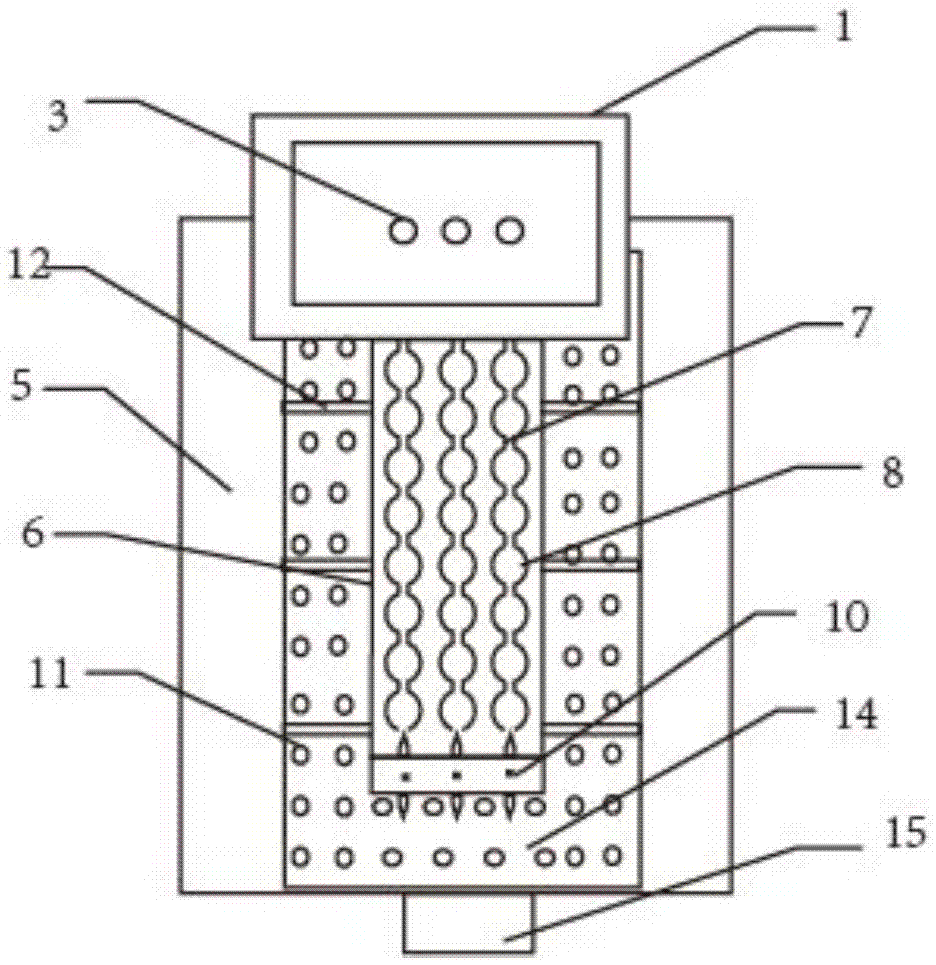

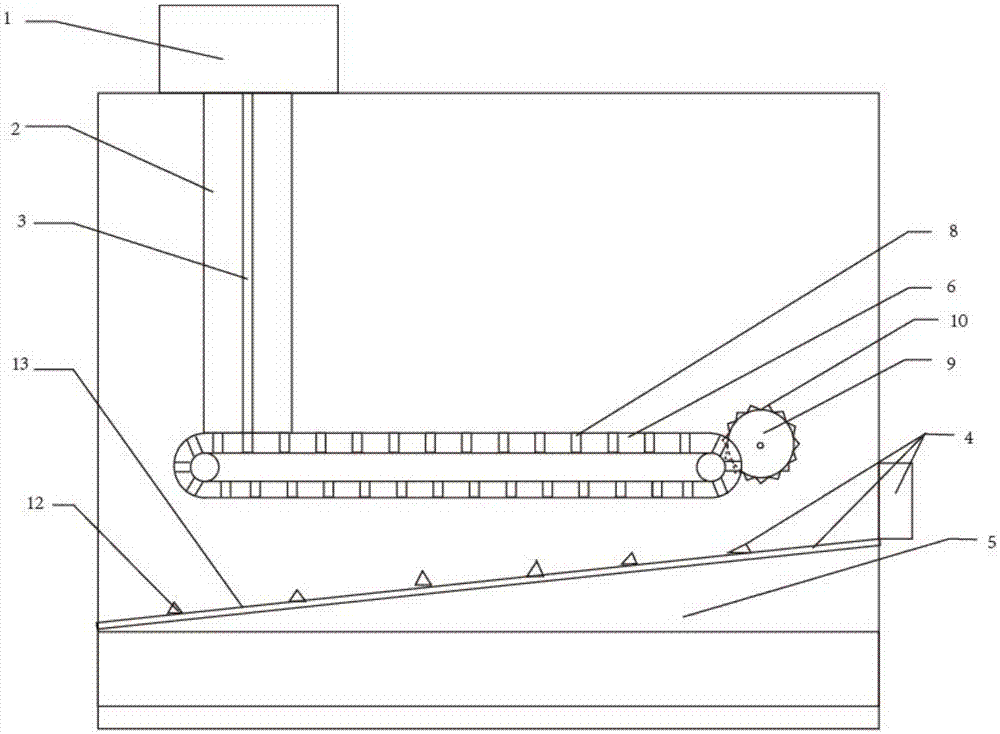

[0018] Such as Figure 1-2 As shown, a hard capsule powder returning device provided by the present invention includes a feeding funnel 1, a longitudinal channel connected to the feeding funnel 1, a longitudinal channel 2 provided with a capsule channel 3 through which a number of single capsules pass, and an oscillation device 4 , Collection trough 5, conveyor belt 6, capsule shell outlet 15, conveyor belt 6 is provided with a cavity 7 parallel to the conveying direction, cavity 7 is provided with a capsule groove 8 matching the capsule, and the end of the conveyor belt 6 is provided with a cutting wheel 9. The cutting wheel 9 is provided with a serrated protrusion 10, and the rotation direction of the cutting wheel 9 is counterclockwise; a screen 14 is provided on the oscillating device, and a screen hole 11 is provided on the screen 14, and the plane of the screen 14 is inclined Plane, the angle between the plane of the screen 14 and the horizontal plane is 5°, the screen 14 ...

Embodiment 2

[0020] Such as Figure 2-3 As shown, a hard capsule powder returning device provided by the present invention includes a feeding funnel 1, a longitudinal channel connected to the feeding funnel 1, a longitudinal channel 2 provided with a capsule channel 3 through which a number of single capsules pass, and an oscillation device 4 , Collection tank 5, conveyor belt 6, the conveyor belt 6 is provided with a cavity 7 parallel to the conveying direction, the cavity 7 is provided with a capsule groove 8 matching the capsule, and the end of the conveyor belt 6 is provided with a cutting wheel 9 and a cutting wheel 9 There is a serrated protrusion 10, the rotation direction of the cutting wheel 9 is counterclockwise; a screen 14 is provided on the oscillating device, the screen is provided with a screen hole 11, the plane of the screen 14 is an inclined plane, and the plane of the screen 14 is located The angle with the horizontal plane is 30°, the screen 14 is provided with a triangu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com