Food safety testing sampling box

A food safety and sampling box technology, applied in the types of packaging items, impact-sensitive items, internal accessories, etc., can solve the problems of inconvenience and single function, and achieve the effects of convenient use, improved accuracy, and guaranteed stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

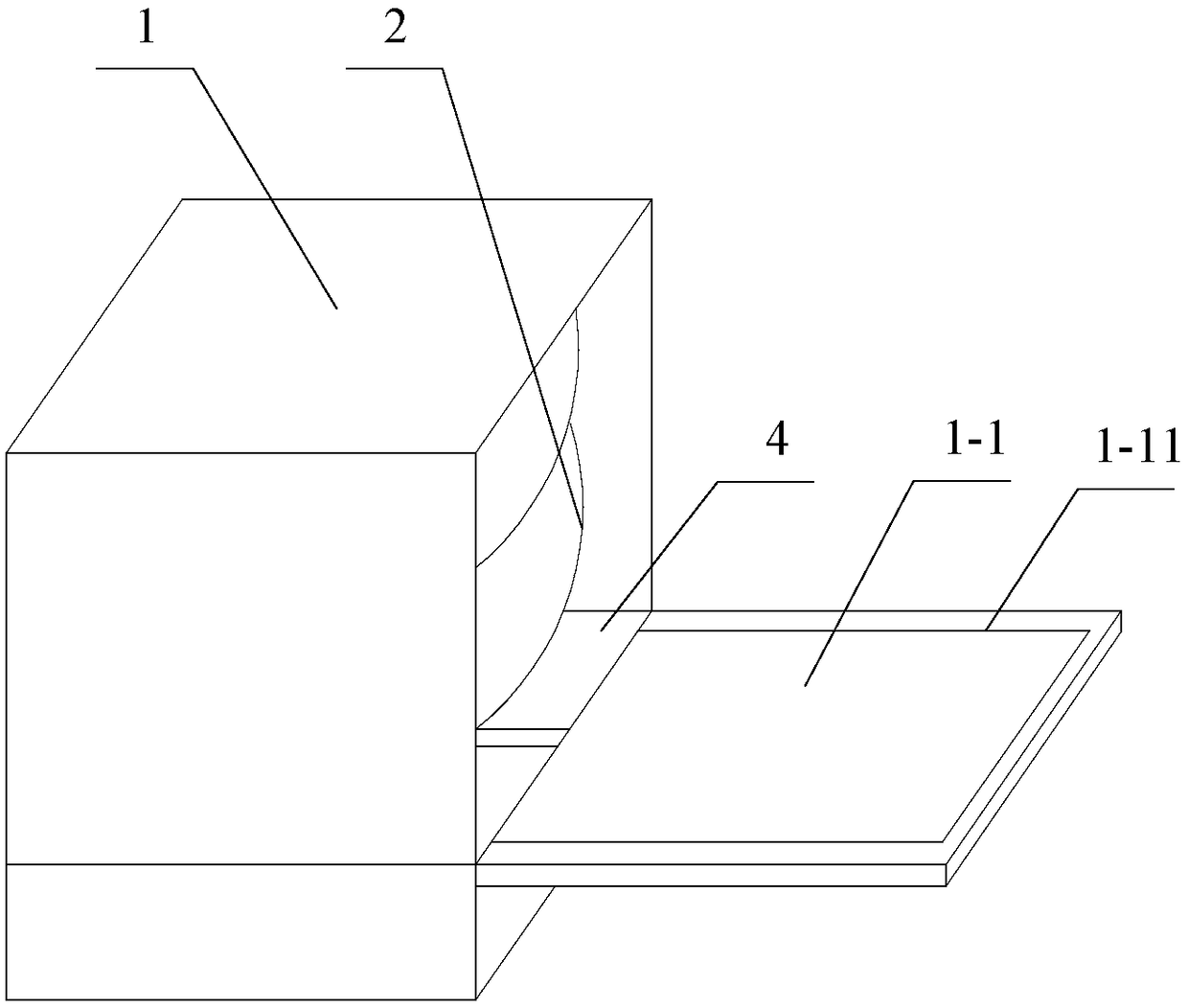

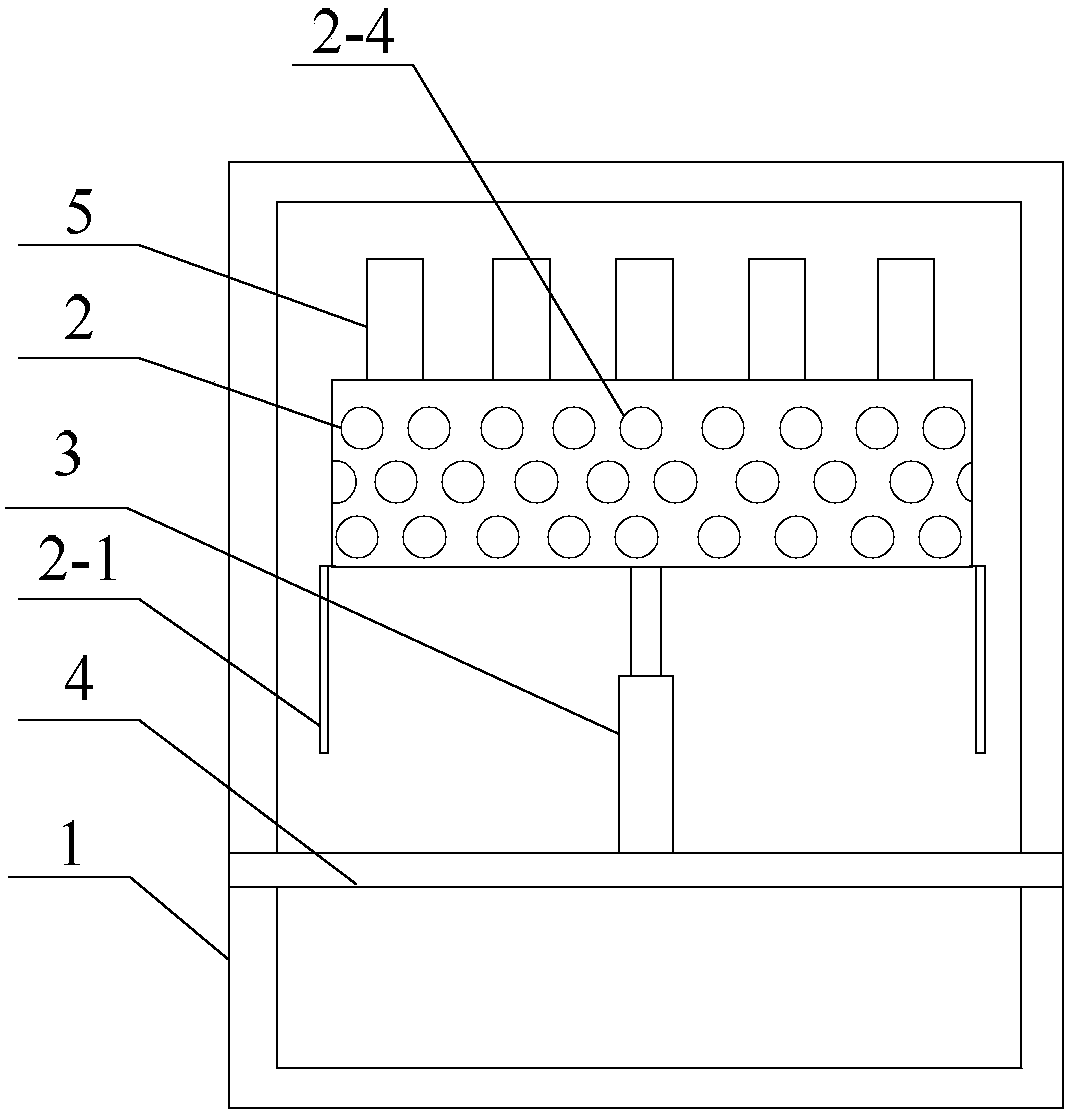

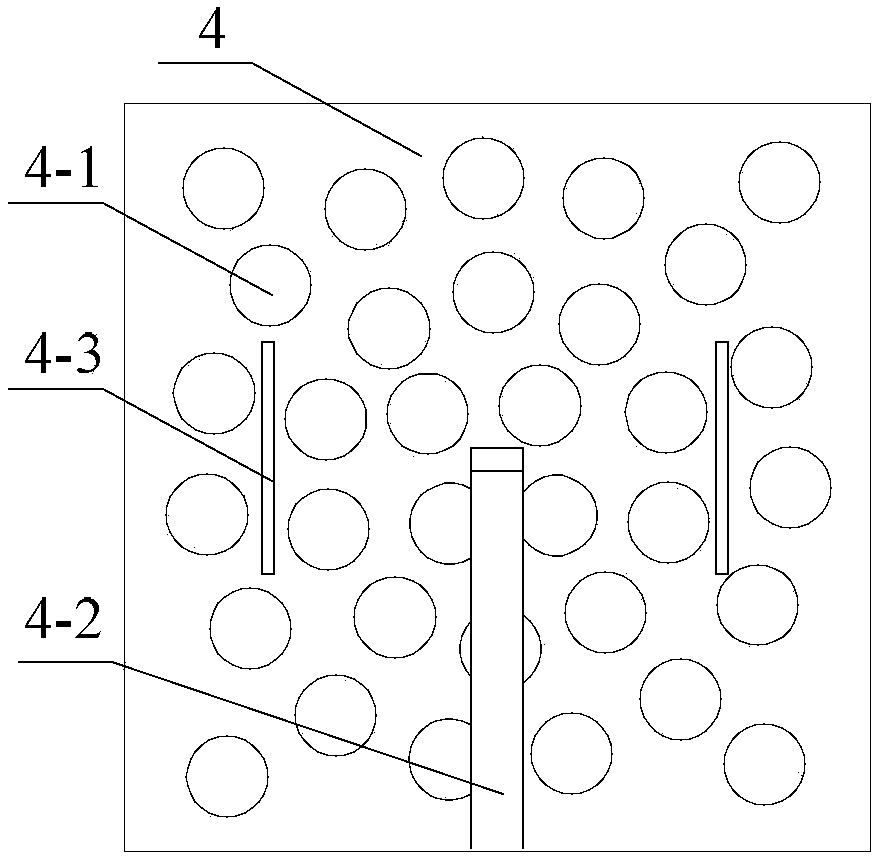

[0018] Specific implementation mode one: the following combination Figure 1 to Figure 5 Describe this embodiment, the food safety detection and sampling box described in this embodiment includes a box body 1, and it is characterized in that it also includes a test tube insert 2, a telescopic support shaft 3, a partition plate 4 and a plurality of test tubes 5,

[0019] The inner cavity of the box body 1 is divided into an upper sampling section and a lower cooling section by a section partition plate 4, and a side wall of the upper sampling section is a side box door 1-1, which is hingedly connected with the box body body; In the sampling interval, the center of the upper surface of the partition plate 4 is fixedly connected to the sliding end of the telescopic support shaft 3, and the telescopic end of the telescopic support shaft 3 is rotatably connected to the outer surface of the bottom of the test tube insert 2; refrigerant is placed in the lower cooling interval;

[002...

specific Embodiment approach 2

[0024] Specific implementation mode two: the following combination Figure 4 Describe this embodiment, this embodiment will further explain Embodiment 1, the sampling box also includes a test tube identification mark 6, on the outer wall of the test tube insert 2, corresponding to each radial insert on the insert plate 2-3 An identification mark 6 is set on the branch of the hole 2-31.

[0025] The identification mark 6 can be a digital sequence mark or other marks that are easy to distinguish and memorize. In this way, labels are set on each radial branch of the test tube, and the storage and distinction of samples will be more convenient. The differential storage of sampling samples is more suitable for the needs of food samples for inspection at any time. The stored samples are distinguished by identifying the marks 6, effectively distinguishing different types of samples, and avoiding the cumbersome steps of specially marking the test tubes.

specific Embodiment approach 3

[0026] Embodiment 3: This embodiment further describes Embodiment 1 or 2. The shell of the box body 1 has a vacuum interlayer, the outer surface of the outer shell is provided with a heat insulating layer, and the inner surface of the inner shell is provided with an insulating layer.

[0027] The vacuum interlayer can better ensure that the inside of the box does not exchange temperature with the outside environment, and it is equipped with a heat insulation layer and an insulation layer, so that the food samples in the test tube have a safer and more suitable storage space.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com