Pulverized coal gasification control method and pulverized coal gasification device

A control method and technology of coal gasification, applied in the direction of granular/powder fuel gasification, gasification process, manufacture of combustible gas, etc., can solve the hidden dangers caused by increased consumption, consumption of fuel gas and oxygen, and multi-burner oxygen flow balance and other problems to achieve the effect of prolonging the service life, avoiding the waste of energy and ensuring the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] 【Gasification device】

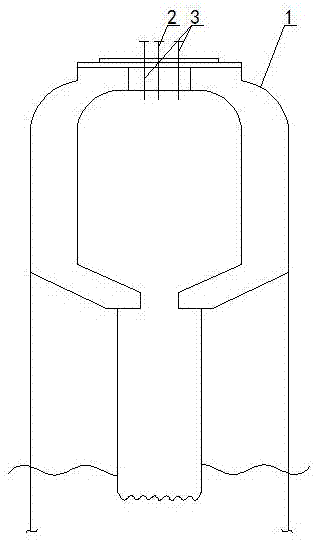

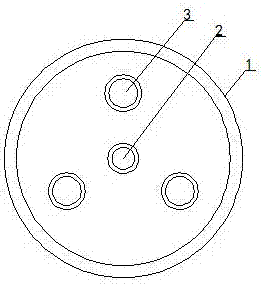

[0033] as attached figure 1 , 2 As shown, the pulverized coal gasification device of the present invention includes a furnace body 1 , a start-up burner 2 and three process burners 3 . Both the starting burner 2 and the process burner 3 are arranged vertically on the top of the furnace body 1 . The start-up burner 2 is assembled in the center position of the furnace body 1 top. The three process burners 3 are evenly distributed around the starting burner 2 .

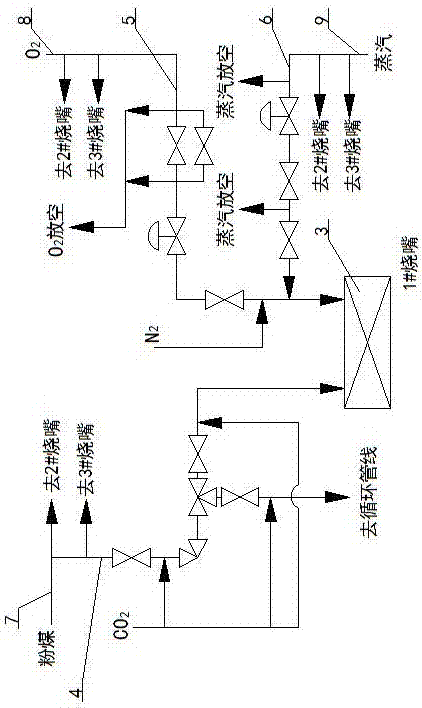

[0034] as attached image 3 As shown, each process burner 3 passes through its own pulverized coal branch pipeline 4, gasification agent branch pipeline (including oxygen branch pipeline 5 and steam branch pipeline 6) and pulverized coal main pipe 7, oxygen main pipe 8 and Steam main pipe 9 is connected.

[0035] The layout method of the control valves on the pulverized coal branch pipeline 4, the oxygen branch pipeline 5 and the steam branch pipeline 6 is the same as that on the corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com