A method for detecting the air tightness of ko consolidation instrument

A detection method and consolidation instrument technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and by measuring the increase and deceleration rate of fluid, etc., which can solve the problem of pressure sensor reading fluctuations, inability to apply pressure, and pressure failure, etc. problem, to achieve the effect of simple operation, easy acquisition and convenient detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

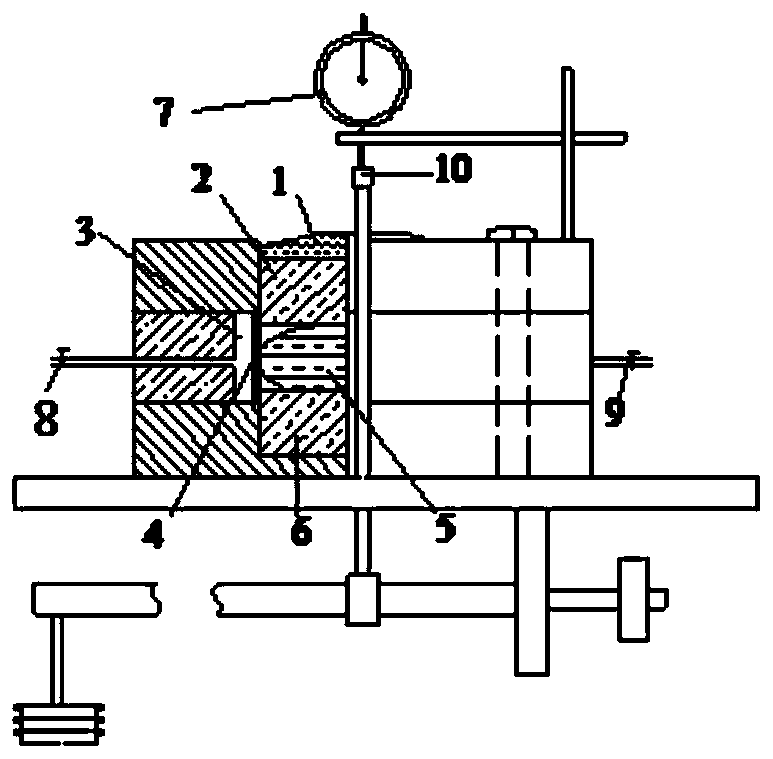

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

[0018] a K 0 The detection method of the airtightness of the consolidation instrument comprises the following steps:

[0019] Step 1: Connect the burette with the water inlet valve 8 with a rubber hose, fill the burette with anaerobic water, open the water inlet valve 8 and the exhaust valve 9, make the water fill the pressure chamber 3, close the water inlet valve 8 and drain Air valve 9, take off the rubber hose connected with water inlet valve 8.

[0020] Step 2: To reduce friction, at K 0 Apply vaseline or silicone grease to the rubber ring or latex film of the consolidation instrument, and put the first calibration block 6 into K 0 In the consolidation instrument, adjust the height of the burette liquid level and K 0 The height difference of the consolidation instrument, when K 0 When the rubber ring or latex film of the consolida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com