Measurement method of transition position of airfoil surface boundary layer based on distributed thermosensitive optical fiber

A measurement method and distributed technology, applied in the direction of measuring devices, measuring heat, thermometers, etc., can solve the problems of deviation of test results, influence of aerodynamic shape, etc., and achieve the effect of improved spatial accuracy, convenient judgment method, and high spatial measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] This embodiment is a method for measuring surface flow transition based on distributed temperature-sensitive optical fibers.

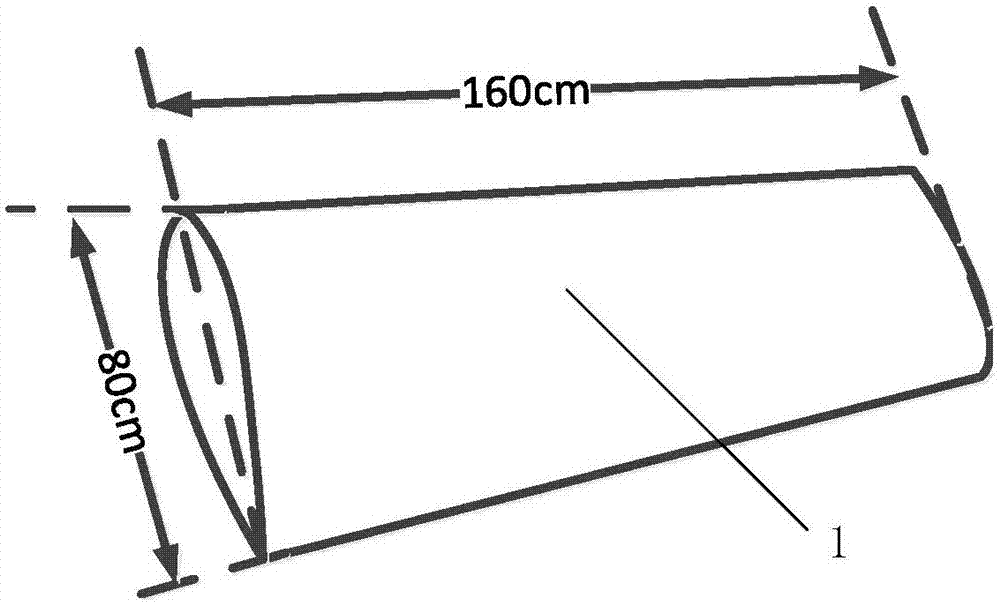

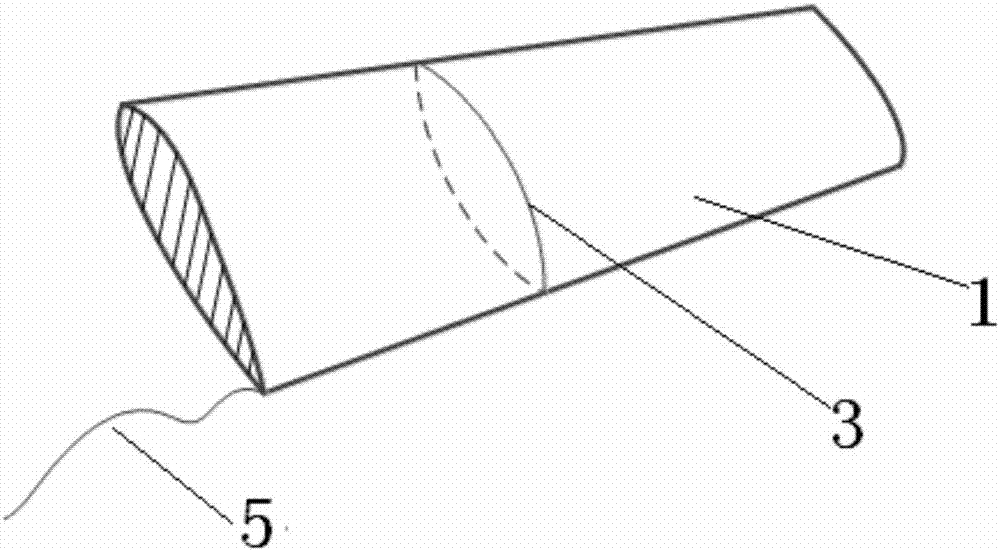

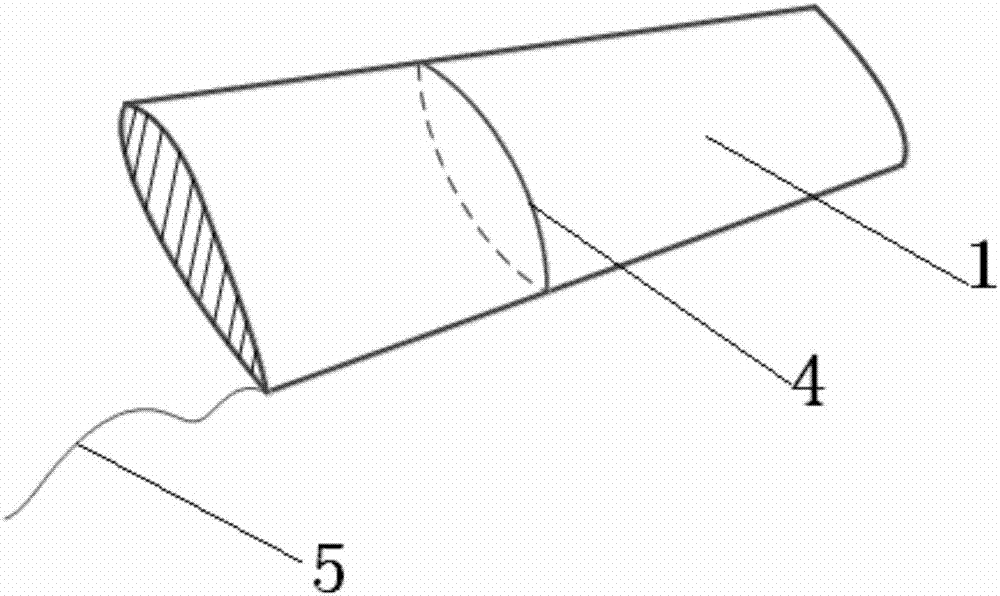

[0049] The optical fiber used in this embodiment is the temperature optical fiber 4 . The optical fiber in the temperature optical fiber 4 casing only feels the temperature change, which can effectively eliminate the problem of thermal coupling. The airfoil model 1 used is attached figure 1 As shown, it is made of aluminum alloy.

[0050] The concrete implementation process of this embodiment:

[0051] Step 1, airfoil model installation:

[0052] The airfoil model 1 is installed in the wind tunnel 7 according to the conventional method, and is fixedly connected with the lower turntable 2 of the wind tunnel, as attached figure 2 shown. The angle of attack of the airfoil model 1 can be adjusted by turning the lower turntable 2 of the wind tunnel.

[0053] Step 2, laying optical fiber:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com