Anti-scratch coated reflective sheet and preparation method thereof

A reflective sheet and anti-scratch technology, which is applied in the field of polyester film, can solve the problems of easily producing shadows and easily scratching the light guide plate, and achieve the effects of preventing adsorption, simple process, and avoiding scratching the light guide plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

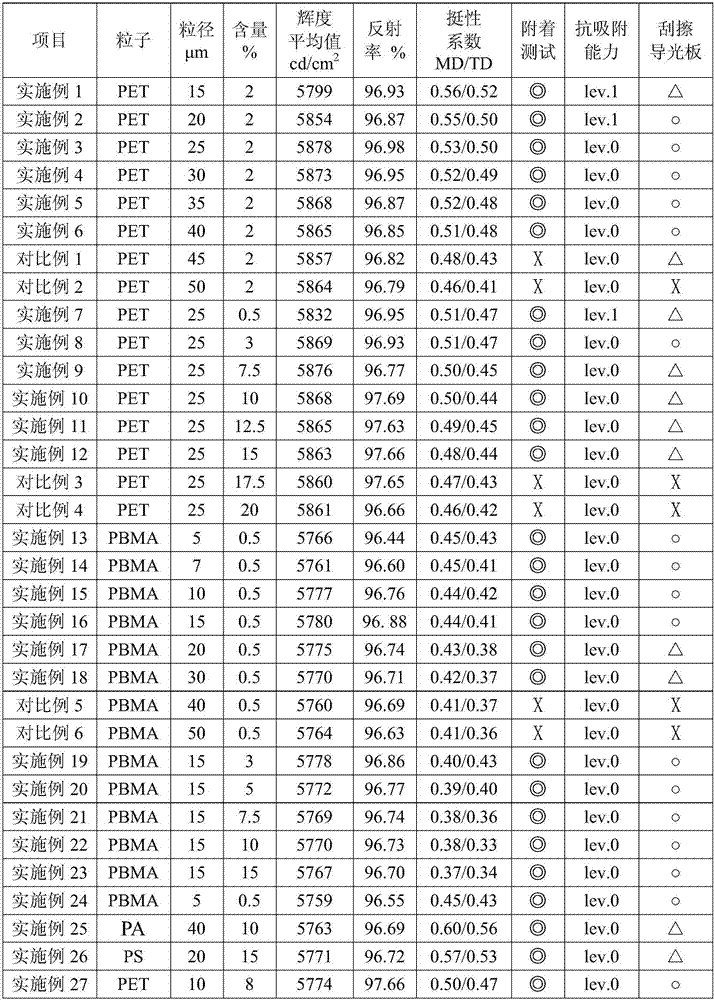

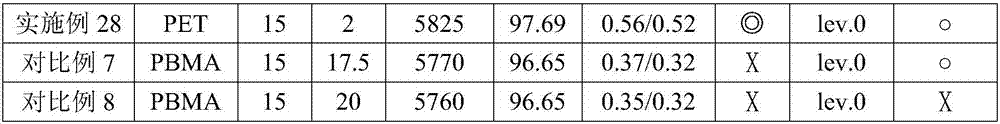

Embodiment 1

[0071] The anti-scratch coated reflective sheet provided by the present invention includes a reflective sheet and a coating layer positioned on the surface of the reflective sheet, and the main layer of the reflective sheet includes TiO with a mass fraction of 5%. 2 , the average particle size of the particles is 0.2 μm, and the mass fraction is 10% polypropylene resin (produced by Borealis, the product model is WF420HMS), 85% polyester resin (PET film grade chips produced by China Yizheng Chemical Fiber Co., Ltd., commodity The grade is FG620); the auxiliary layer of the reflection sheet includes an antistatic agent (plastic antistatic agent 006 produced by Zhongteng Chemical Co., Ltd.) with a mass fraction of 8%, and a hindered amine light stabilizer poly﹛[ 6-[(1,1,3,3-tetramethylbutyl)-amino]]1,3,5-triazine-2,4-bis[(2,2,6,6-tetramethyl- Piperidinyl)-imino]-1,6-hexadiene-[(2,2,6,6-tetramethyl-4-piperidinyl)-imino]﹜ (trade name is CH944, manufactured by BASF Produced by the ...

Embodiment 2

[0078] A coated reflective sheet was fabricated in the same manner as in Example 1, except that the average particle diameter of the PET particles in the coating layer was replaced with particles of 20 μm as in the reflective sheet provided in Example 1. The evaluation results are summarized in Table 1.

Embodiment 3

[0080] The reflective sheet provided in Example 1, except that the average particle diameter of the PET particles in the coating layer is replaced by particles of 25 μm, and the TiO in the main layer of the reflective sheet 2 A coated reflective sheet was produced in the same manner as in Example 1 except that the average particle diameter of the particles was 0.4 μm. The evaluation results are summarized in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com