Preparation method of polished glutinous rice tea wine

A technology of glutinous rice and tea wine, which is applied in the field of food processing, can solve the problems of poor compatibility of tea and wine, layering, precipitation, uneven color, etc., and achieve the effects of rich and long-lasting aroma, prolonging the shelf life and reducing microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a kind of preparation method of glutinous rice tea wine, comprises the following steps:

[0030] Step 1: Soak the frozen tea leaves in hot water with a temperature above 95°C for 2 to 3 times in a row, and collect the soaking liquid each time into the first tea liquid. , 3 leaves tender shoots as raw materials, the frozen tealeaves made through the steps of sun drying, shaking green, killing green, wrapping, hair fire, wrapping again, deblocking and quick freezing steps, wherein, drying green leaves loses weight by 7-8wt%, shaking The number of greens is 5 times, and the green leaves are slightly thinned and fermented in the later stage. The finishing temperature is 320°C, and the weight loss is 60wt%. 90~110℃, cold pack kneading and quick freezing at low temperature;

[0031] Step 2: Rinse the dried glutinous rice, soak the rinsed glutinous rice in the first tea liquid obtained in step 1, until the color of the glutinous rice is light yellow-gre...

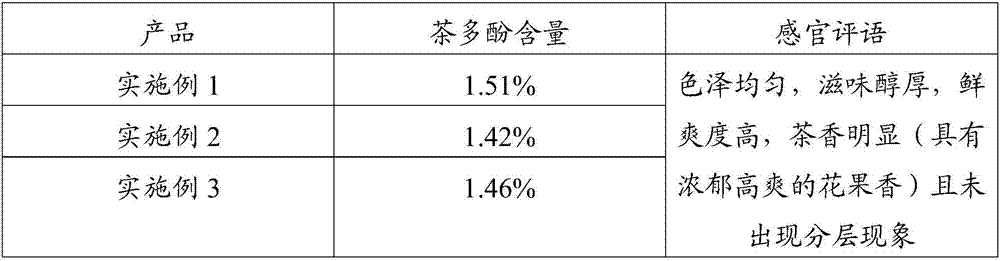

Embodiment 1

[0059] A preparation method of glutinous rice tea wine, comprising the following steps:

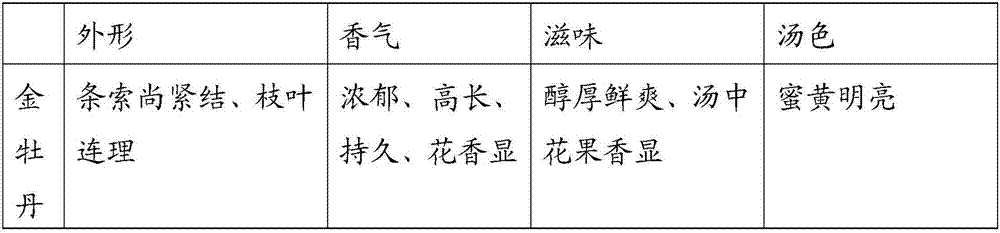

[0060] Step a: Select the young shoots of 2 and 3 leaves of the high-fragrance oolong tea variety (Golden Peony) as the raw material, and go through sun-drying, shaking, killing, kneading, hair-fire, kneading again, and drying Frozen oolong tea is obtained through block and quick-freezing steps, wherein, drying green leaves reduces weight by 7-8wt%, and shaking green leaves is 5 times. 60wt%, the way of kneading and kneading again is moisture recovery cold pack kneading, the hair fire temperature is 90-110°C, and the cold pack kneaded is then frozen at low temperature. The quality of the obtained frozen oolong tea (Golden Peony) is shown in Table 1;

[0061] Step b: Soak the frozen oolong tea in step a with freshly boiled water, soak twice continuously, and collect the soaking liquid each time into the first tea liquid, wherein the time of each soaking is controlled at 2.5min, and the hea...

Embodiment 2

[0069] This embodiment is the same as the method of embodiment 1, the difference is that

[0070] Step b: Soak the frozen oolong tea in step a with freshly boiled water for 3 consecutive times, and collect the soaking liquid each time into the first tea liquid, wherein the time of each soaking is controlled at 3.5min, and the heat used for each soaking is controlled at 3.5 minutes. The mass ratio of water to the frozen oolong tea is 22:1;

[0071] The temperature of controlled fermentation is 22 DEG C in step e, and the addition amount of described distiller's yeast is 2.2% of dry glutinous rice mass in step 2;

[0072] Step f: Brew frozen tea leaves with boiled pure water to obtain brewing liquid, brew continuously for 7-10 times, and collect each brewing liquid into a second tea liquid, and dry the second tea liquid according to step c 1.6 times the mass of glutinous rice is mixed into the glutinous rice in the ceramic tank of step e for re-fermentation, and the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com