Method for detecting degree of corrosion of anchor bolt of electric transmission line

A technology for transmission lines and transmission line towers, which is applied in the field of detection of the corrosion degree of corner bolts of transmission lines, can solve problems such as the influence of accuracy and sensitivity, the reduction of sensitivity and accuracy, and deviation from the normal reflection track, so as to improve the matching degree, The effect of high accuracy and reduced risk of overturning

Active Publication Date: 2017-07-04

ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +2

View PDF2 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

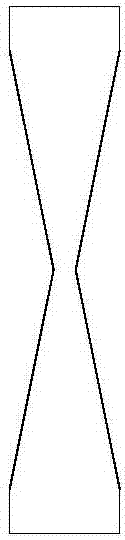

Under normal circumstances, the corrosion of anchor bolts is a large area of surface corrosion within a certain range. The corrosion sections may not be exactly the same everywhere, but the corrosion boundary is smooth, and the outer surface is covered with oxide scales of different thicknesses. When transmission lines When the service time is long and the corrosive medium of the soil is strong, the corrosive medium enters the foundation through the mature concrete, and serious corrosion occurs in the long range of the anchor bolts. For this kind of concealed corrosion defects, the traditional fastening bolts are used The phased array detection method is used to detect this kind of corrosion appearance of anchor bolts, the sensitivity and accuracy of phased array detection are greatly reduced; and in the corrosion section, due to the unevenness of the corrosion surface, the reflection of ultrasonic waves is also different. It will cause the loss of a lot of reflected waves, or deviate from the normal reflection track, forming interference waves, which will seriously affect the accuracy and sensitivity of the detection, especially when the detection length (the distance between the probe detection end face and the position to be detected) reaches more than 300mm , this problem is more serious

Therefore, there is currently no detection method that can accurately detect the degree of corrosion of anchor bolts.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0069] (1) Detection method

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Login to View More

Abstract

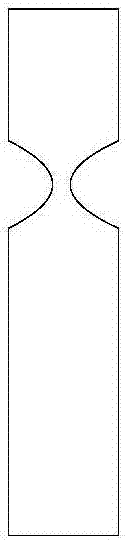

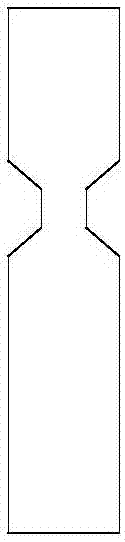

The invention provides a method for detecting a degree of corrosion of an anchor bolt of an electric transmission line. The method comprises selecting a phased array probe according to the bolt diameter and length, debugging a phased array instrument, vertically arranging the phased array probe at the end of an anchor bolt to be detected, and carrying out detection through adjusting a detection range of the phased array instrument along with rotation of the probe. The end of the bolt is an end of the anchor bolt to be detected out of a reinforced concrete foundation bolt. The method detects corrosion conditions of an anchor bolt of an electric transmission line. The method utilizes a phased array technology, utilizes a specified probe, is used for observation of bolt corrosion conditions, has simple processes, can be operated conveniently and has good practicability.

Description

technical field [0001] The invention belongs to the field of transmission line operation and maintenance, and in particular relates to a detection method for the corrosion degree of corner bolts of the transmission line. Background technique [0002] Transmission tower is a kind of high-rise structure that is widely used in overhead transmission lines. As an important "lifeline" for power transmission, transmission lines play an important role in the reliable operation of transmission towers. Usually, transmission towers are built through reinforced concrete foundations buried deep in the soil. In a fixed position, the transmission tower is firmly fixed on the reinforced concrete foundation by means of corner bolts. Most of the anchor bolts are buried in the foundation under the soil, and a small part is located in the nuts and the bottom plate of the tower foot. Due to the long corridor of the transmission line, The landform and climate environment are complex, and the anch...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N17/04

CPCG01N17/04

Inventor 李志明张忠文李新梅杜宝帅邓化凌赵水业菅广营张广成李正利季善浩

Owner ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com