Rock property test system and rock damage evolution test method

A technology for testing systems and rock properties, applied in measuring devices, material analysis using acoustic wave emission technology, instruments, etc., can solve the problems of limited applicability, high research costs, discrete macroscopic mechanical behavior, etc., and achieve the goal of overcoming geometric shapes Effects of restrictions, reliable method support, and low research costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

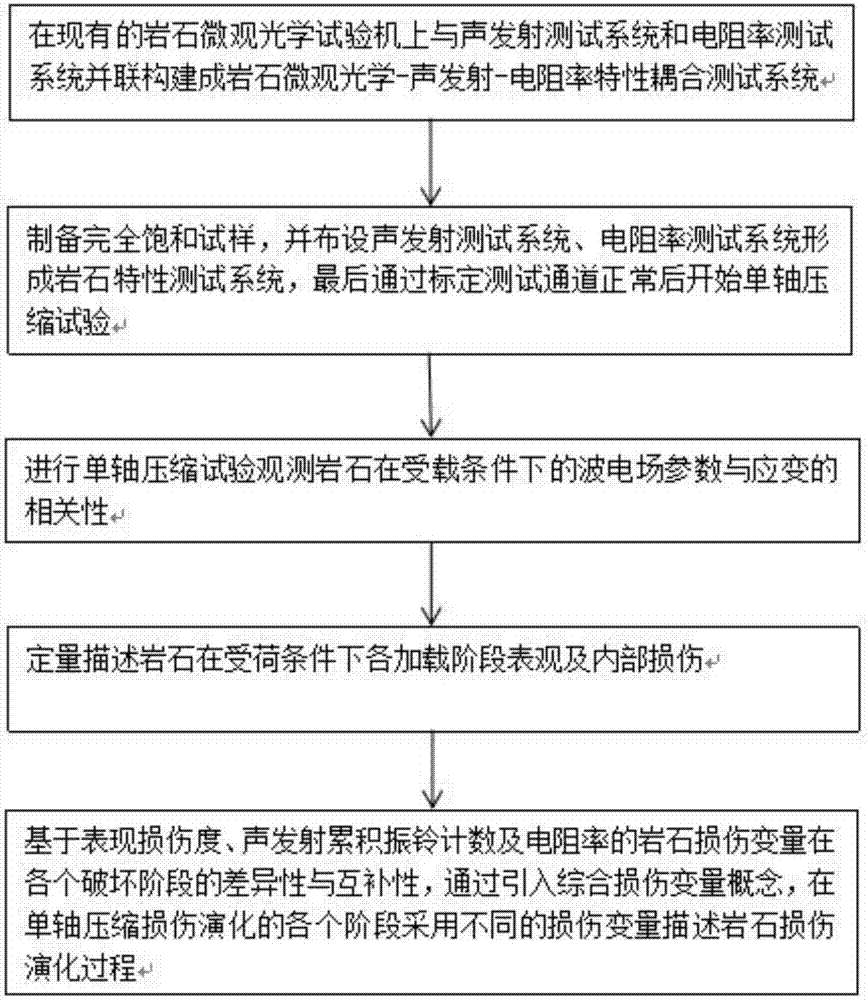

[0034] Such as figure 2 As shown, the rock damage evolution test method of the present invention is carried out successively according to the following steps:

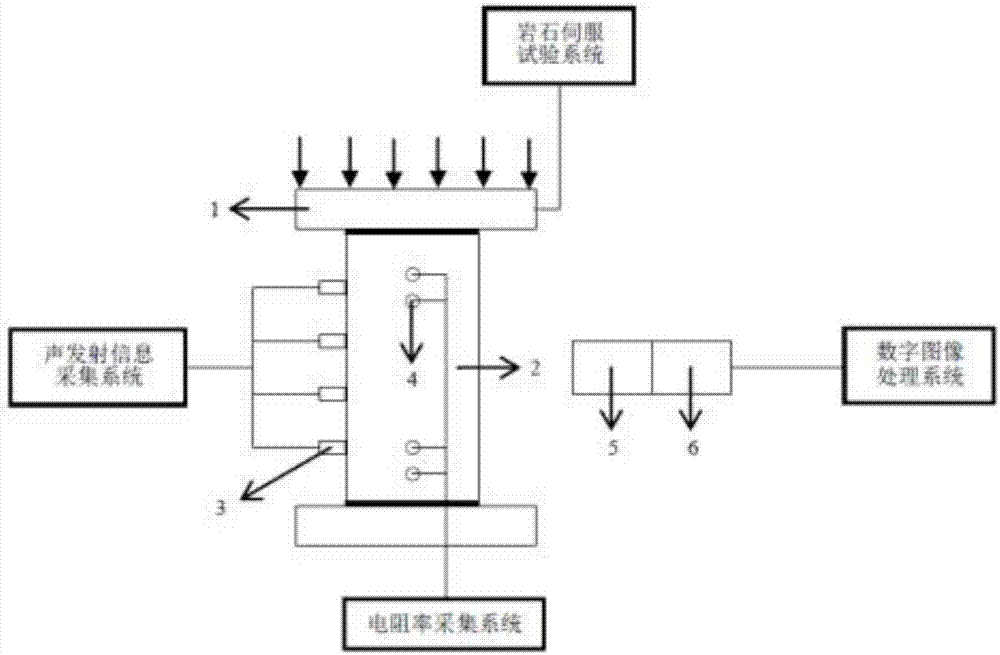

[0035] (1) Construct a rock micro-optics-acoustic emission-resistivity characteristic coupling test system. On the basis of the existing micro-optics testing machine, connect the PCI-8 rock acoustic emission test system and the V8 rock resistivity test system in parallel. The acoustic emission test The system and the resistivity test system are both high-speed sensitive real-time data acquisition systems, which can measure the changes in acoustic emission parameters and resistivity at the moment of rock fracture. The working frequency of the system is about 1.0kHz ~ 2.4MHz.

[0036] (2) A granite core sample with a height of 100mm and a diameter of 50mm was drilled indoors. Both ends...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com