High-power eutectic solder inversion structure for ultraviolet LED chip

A LED chip, high-power technology, applied in the direction of electrical components, electric solid devices, circuits, etc., can solve problems affecting stability, heat dissipation, and service life, so as to improve the light output rate and service life, increase the light output rate, and improve The effect of light output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

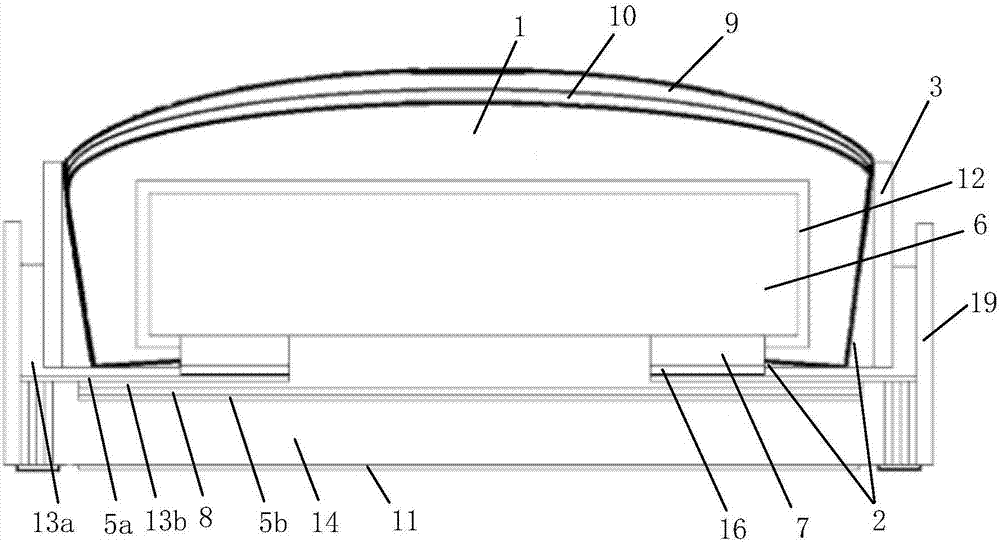

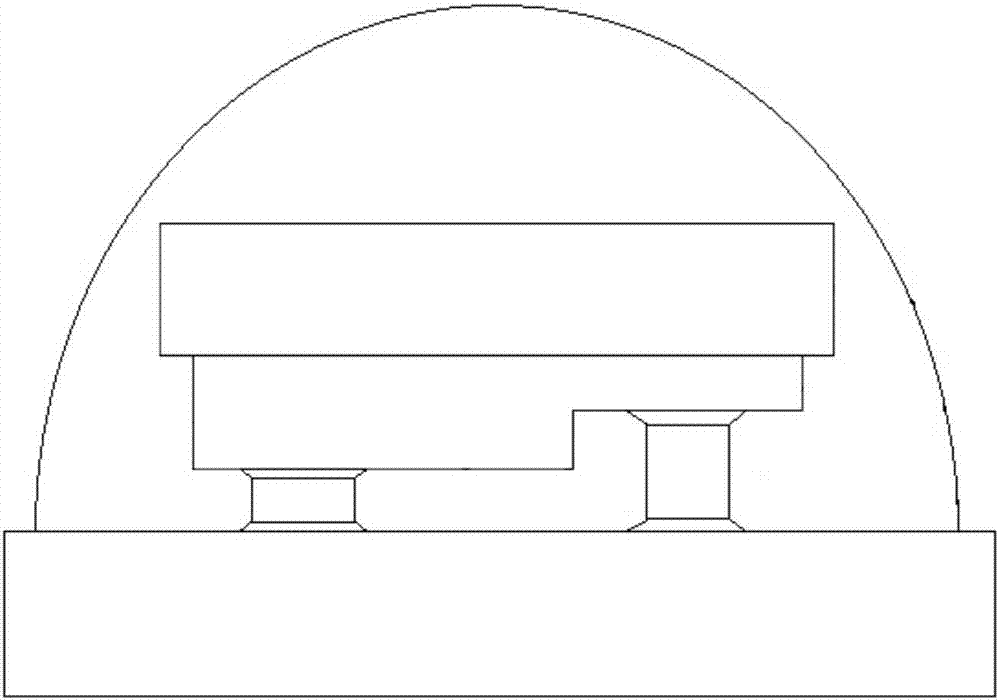

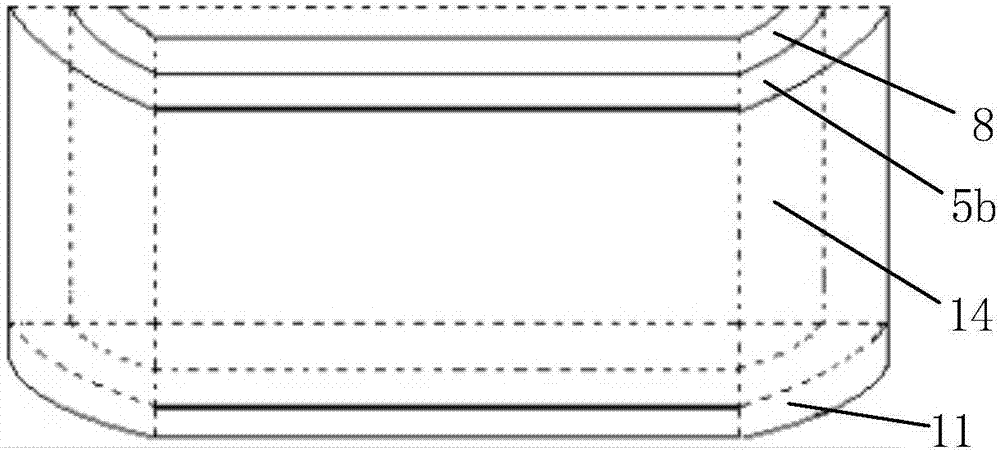

[0051] like figure 1 As shown, the present invention discloses a high-power ultraviolet LED chip eutectic soldering flip-chip structure, which mainly includes an ultraviolet LED chip 6, a packaging adhesive layer 1, a reflective cup 2, a first copper layer 5a, a welding pad 7, and a lens 9. An anti-reflection film 10 and a silicone layer 12 . The LED chip 6 is sequentially welded on the first copper layer 5 a through the pad 7 and the conductive and thermally conductive adhesive layer 16 , and the two copper layers are separated and insulated from each other. The right triangle reflective cup 2 is fixed on the first copper layer 5a through the first thermally conductive adhesive layer 13a, and is connected with the first copper layer 5a. The reflective cup 2 is used to reflect part of the ultraviolet light emitted from the LED chip 6 to the side and to fix the packaging form of the LED.

[0052] Among them, the production of the micro PCB substrate uses a mold to grow the s...

Embodiment approach

[0076] In addition, the heat dissipation structure of the miniature PCB substrate also has another embodiment: the middle part of the miniature PCB substrate 4 is provided with a slot for accelerating heat dissipation, and the slot extends from the upper surface layer of the substrate to the lower surface layer and runs through the entire surface. block substrate. The second thermally conductive adhesive layer 13b extends into the slot and fills up the slot, thereby forming a convex-convex structure, so that the heat generated by the LED chip 6 can be quickly dissipated from the bottom to obtain a better heat dissipation effect.

[0077] Further, the positive and negative electrode strips at both ends of the micro PCB substrate 4 are composed of independent, parallel sub-electrode strips at a certain interval, and the electrode strips are used as a bridge connecting the inside of the LED chip 6 with the external circuit. The parallel connection of the sub-electrode strips ensu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com