Transparent OLED device structure and preparation method thereof

A device structure and transparent technology, applied in semiconductor/solid-state device manufacturing, electrical solid-state devices, semiconductor devices, etc., can solve problems affecting conductivity and luminous efficiency, and achieve improved transmittance, light extraction efficiency, and increased light intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

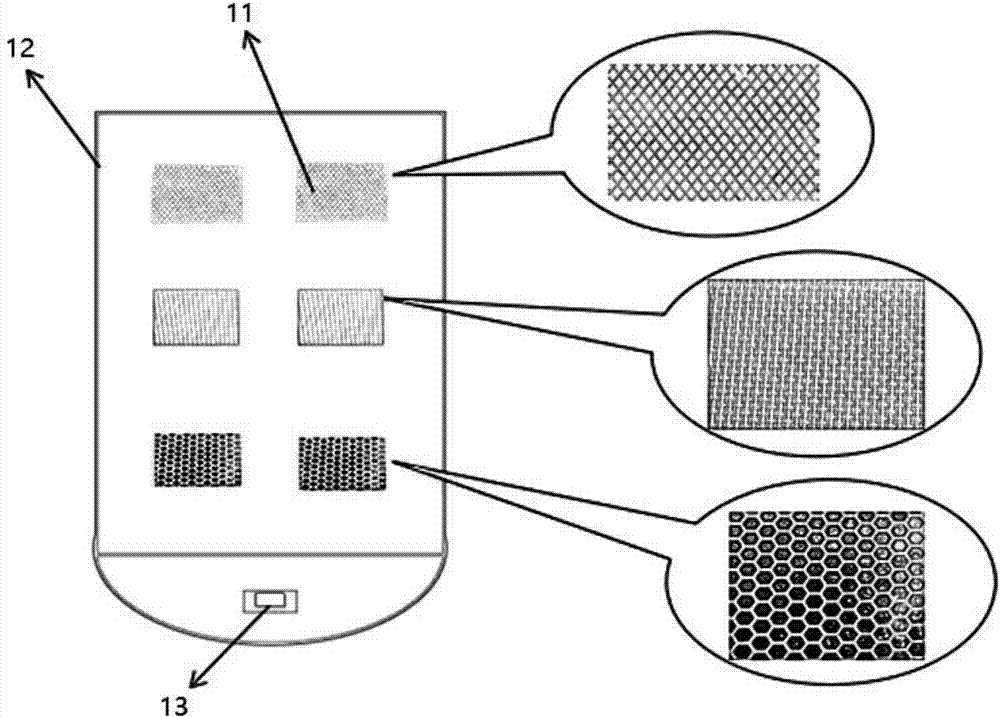

[0028] A preparation process of a transparent OLED comprises a new mesh reticle with an aperture size of 10-500 μm used in the preparation of the device. The thickness of the new mesh reticle is 0.1-0.5 mm, and the shape of the mesh of the reticle can be circle, rhombus, pentagon and hexagon. In addition, in addition to the above-mentioned mesh structure part, a 0.5-0.6 mm etched band part should be reserved.

[0029] Such as figure 2 As shown, the mesh reticle can be applied to prepare OLED cathodes by high vacuum evaporation or magnetron sputtering. And using the mask to prepare transparent OLED can greatly improve the transmittance and efficiency of the device. The material of the new mesh mask is stainless steel alloy sheet or nylon. The thickness of the new mesh reticle is 0.1-0.5mm. The shape of the mesh of the mesh mask plate can be circle, rhombus, square, hexagon and other graphics that can be planarly densely laid. In addition to the above-mentioned mesh struct...

Embodiment 1

[0032] A preparation process of a transparent OLED includes a novel mesh mask plate with an aperture size of 10-500 μm used in the preparation of the device. Wherein, the thickness of the new mesh reticle is 0.1-0.5 mm, and the shape of the mesh of the reticle can be circle, rhombus, pentagon and hexagon. The method of laser engraving is specifically the method of YAG laser combined with dot matrix engraving to obtain various mesh patterns.

[0033] The preparation process is as follows:

[0034] Step 1, preparation of the mask plate: engrave regularly arranged circular small holes on the stainless steel alloy sheet by laser engraving, the radius of the aperture is about 10 μm (the size of the aperture is 20 μm);

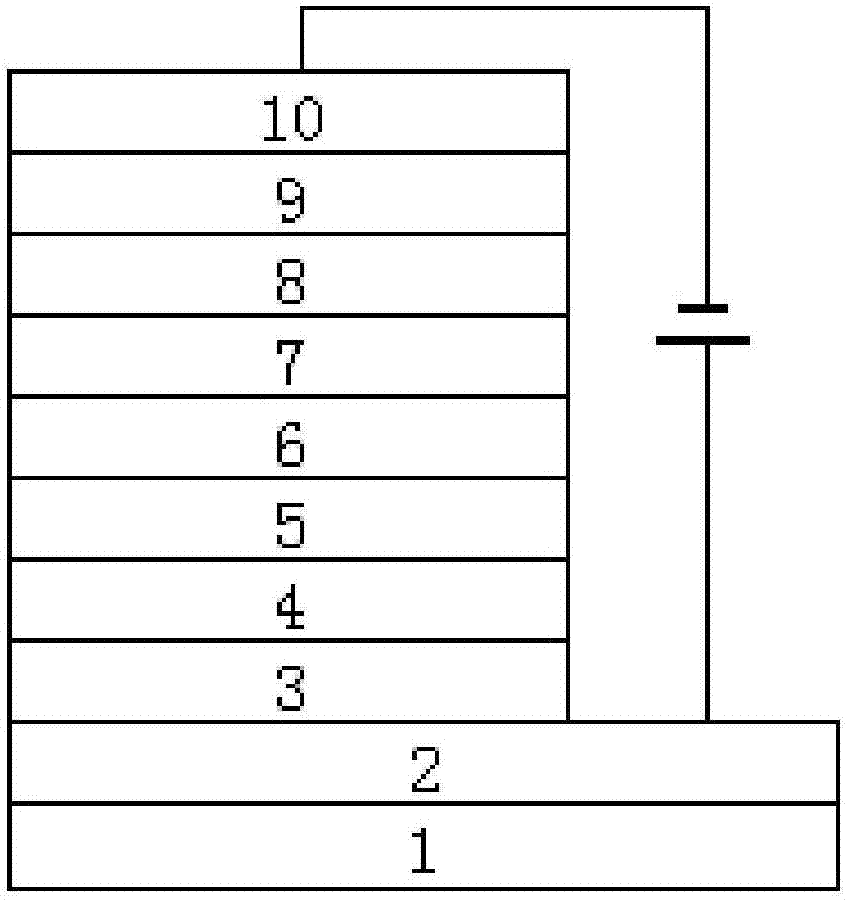

[0035] Step 2, device preparation: the device structure is Glass / ITO / MoO 3 / NPB / Mcp:FIrpic / CBP:R-4B:Ir(ppy) 2 (acac) / BCP / Alq 3 / LiF / Ag:Al (3:1), after vapor-depositing each organic functional layer in sequence, finally vapor-deposit silver-aluminum alloy cathode...

Embodiment 2

[0038] A preparation process of a transparent OLED comprises a new mesh reticle with an aperture size of 10-500 μm used in the preparation of the device. Wherein, the thickness of the new mesh reticle is 0.1-0.5 mm, and the shape of the mesh of the reticle can be circle, rhombus, pentagon and hexagon. The method of laser engraving is specifically the method of YAG laser combined with dot matrix engraving to obtain various mesh patterns.

[0039] The preparation process is as follows:

[0040] Step 1, preparation of the mask plate: engrave regularly arranged diamond-shaped small holes on the stainless steel alloy sheet by laser engraving, and the side length of the rhombus is about 20 μm;

[0041]Step 2, device preparation: the device structure is Glass / ITO / MoO 3 / NPB / Mcp:FIrpic / CBP:R-4B:Ir(ppy) 2 (acac) / BCP / Alq 3 / LiF / Ag:Al (3:1), after vapor-depositing each organic functional layer in sequence, finally vapor-deposit silver-aluminum alloy cathode with a mesh mask.

[0042...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com