Process for dedusting, desulphurization, denitration and flue gas purification

A flue gas purification process, desulfurization and denitrification technology, applied in the field of flue gas purification, can solve problems such as high operating costs, high site requirements, and complicated procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

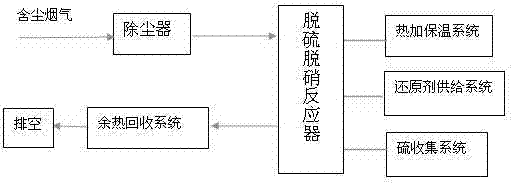

[0011] The dust content of the boiler flue gas is less than 100mg / m3 after the dust is removed by the dust collector 3 , and then the flue gas enters the desulfurization and denitrification reactor. Under the conditions of reducing atmosphere and required temperature, the SO contained in the flue gas 2 is reduced to S and collected by the sulfur collection system, NO x is reduced to N 2 With the flue gas discharged, the flue gas is thoroughly purified. The purified flue gas is discharged through the chimney after the waste heat is recovered by the waste heat recovery system.

[0012] Case 1

[0013] The temperature of the flue gas in the experiment is 200°C, and the dust content of the flue gas is 300mg / m 3 , SO 2 Content 400mg / m 3 , NO 2 Content 300mg / m 3 ,, O 2 The content is 3%, the desulfurization and denitrification reactor temperature is 460°C, and the reducing agent is CH 4 , the amount of reducing agent introduced is 1.1 times of the theoretical requirement. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com