Special fixture for long shaft

A special fixture and long-axis technology, which is applied in the field of processing and manufacturing, can solve the problems of unfavorable factory quality goals and profit goals, the inability to completely offset the bending stress of the long-axis, and high scrap pressure, so as to achieve good clamping stability and reliability. Broad application prospects and promotion value, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and preferred embodiments.

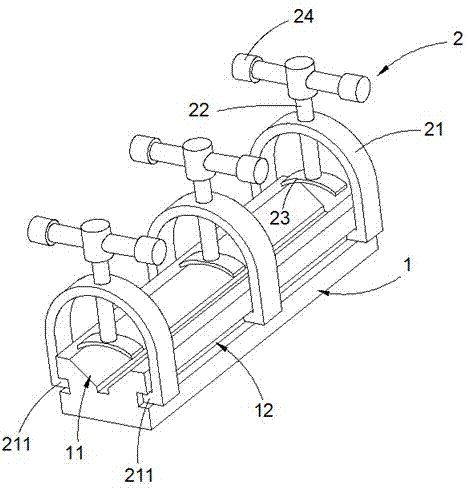

[0016] figure 1 It is a schematic diagram of a preferred embodiment of a long-axis special clamp provided by the present invention. Such as figure 1 As shown, the material of the special fixture for the long axis is stainless steel with excellent performance, which specifically includes a support 1 and three fasteners 2, wherein the top of the support 1 is provided with a centered, end-to-end V-shaped groove 11 , The two side walls of the support 1 are symmetrically provided with two guide rail grooves 12 penetrating from end to end. The cross-sectional shape of the guide rail groove 12 is rectangular, which is convenient for processing and forming. The three fasteners 2 are evenly arranged at the front, middle and rear ends of the support 1 along the direction of the guide rail groove, which can restrain the deformation of each pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com