In-place precision measurement method for three-dimensional shape error of aspheric grinding circular arc diamond grinding wheel

A diamond grinding wheel and precision measurement technology, which is applied to the parts of grinding machine tools, grinding/polishing equipment, metal processing equipment, etc. Radian error and other problems, to achieve the effect of simple measurement process and high measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

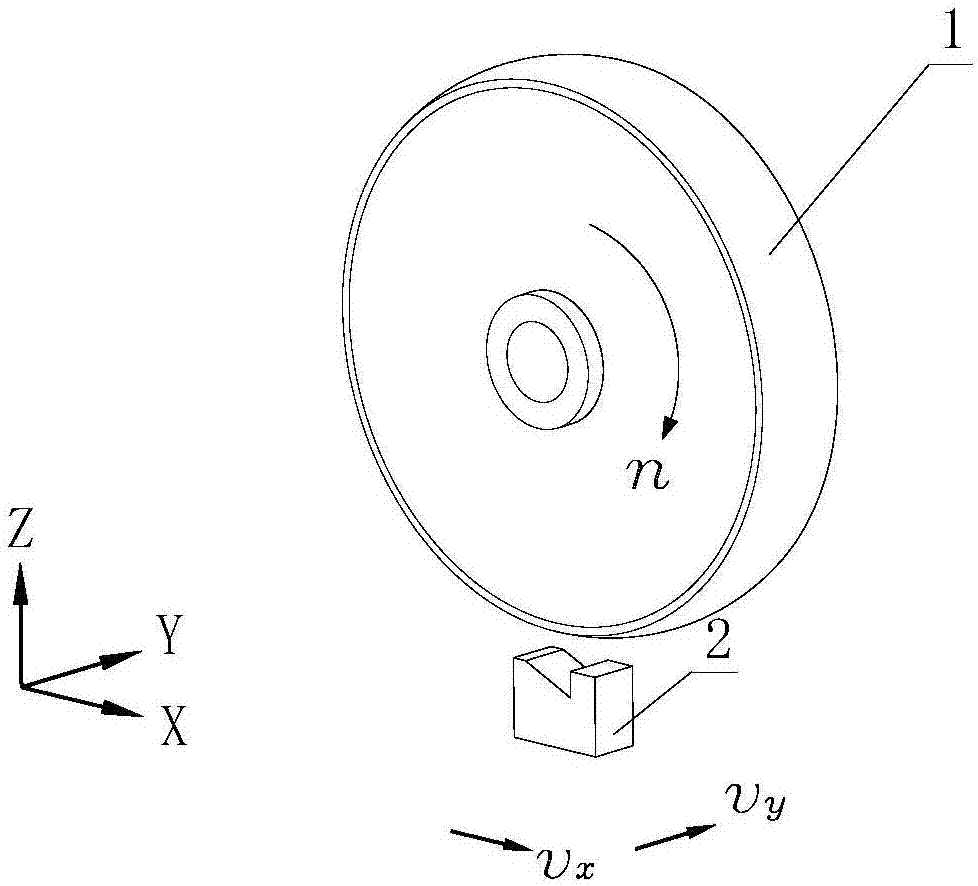

[0047] The measurement object of this embodiment is an arc diamond grinding wheel with a size of Φ400mm×W20mm. Install the diamond grinding wheel on the spindle of the ultra-precision grinding machine, and use a dresser to modify the shape of the grinding wheel. The steps of the in-situ precision measurement method of the present embodiment are as follows:

[0048] 1) Fix the non-contact displacement sensor on the surface of the magnetic table of the machine tool, the direction of the measuring beam is vertically upward, and move the coordinate axis of the machine tool to adjust the spatial position between the sensor probe and the grinding wheel, so that the light spot irradiated by the probe on the surface of the grinding wheel is located on the grinding wheel The lowest point in the X direction, while ensuring that the entire profile of the grinding wheel along the Y direction is within the measurement range of the sensor;

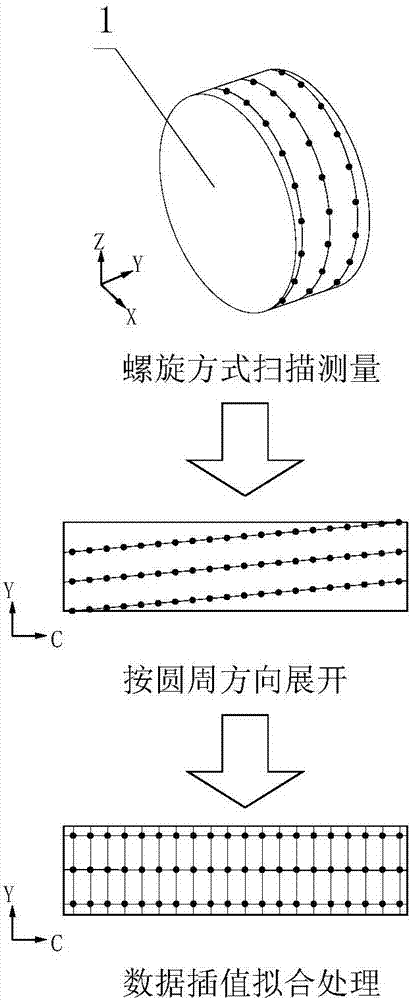

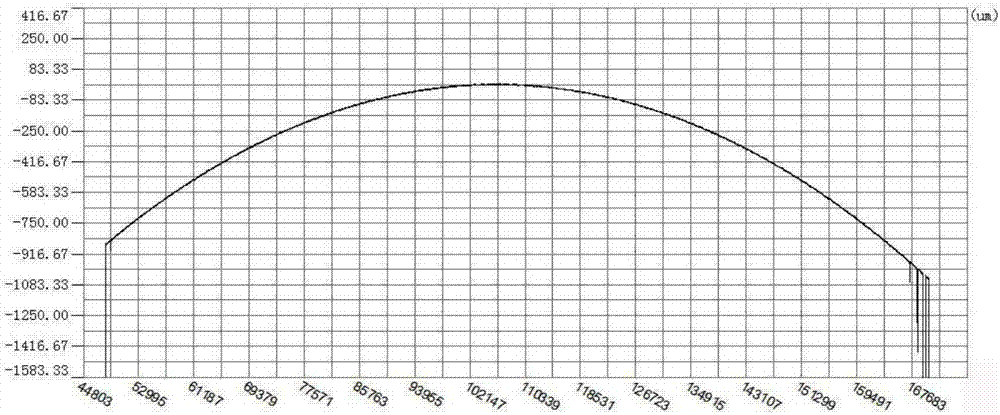

[0049] 2) Move the measuring head along the Y di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com