Wear resistant and crease resistant fiber fabric

A fiber and fabric technology, applied in the field of wear-resistant and anti-wrinkle fiber fabrics, can solve the problems of poor wear-resistant and wrinkle-resistant properties, and achieve the effects of increasing comfort, avoiding rainwater immersion, and promoting the use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

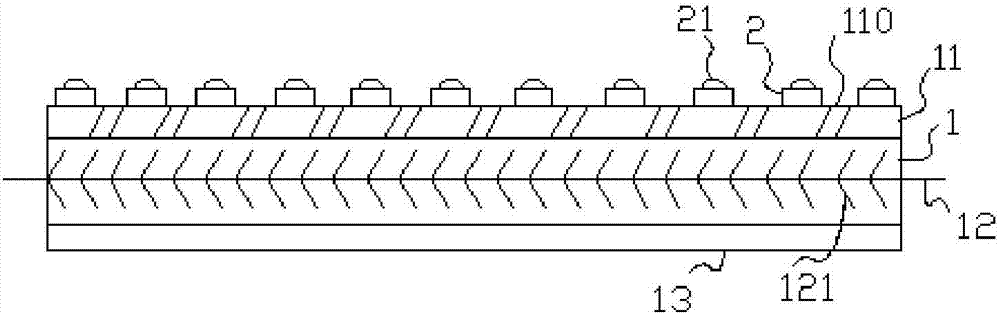

[0023] Such as figure 1 , figure 2 As shown, the structure of this kind of wear-resistant and anti-wrinkle fiber fabric includes a fiber fabric layer 1, the upper surface of the fiber fabric layer 1 is provided with a rubber layer 11, and a plurality of through holes 110 are embedded in the rubber layer 11. The rubber layer can play a wear-resistant role, and can be used in harsh environments, and the through holes can play a ventilation effect, which is beneficial to human skin health.

[0024] In the above embodiment, specifically, several bosses 2 are fixed on the upper surface of the fiber fabric layer 1 between the through holes 110 , and the upper surface of the bosses 2 is provided with spherical protrusions 21 . When in use, the bosses and spherical protrusions can further play a role in wear re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com